Preparation method of immobilized microorganisms embedded with aerogel

A technology for immobilizing microorganisms and aerogels, applied in the direction of being immobilized on/in organic carriers, etc., can solve the problems of easy loss of microorganisms, small growth space, weak anti-toxic ability, etc., and is conducive to growth and reproduction. , good biological affinity, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

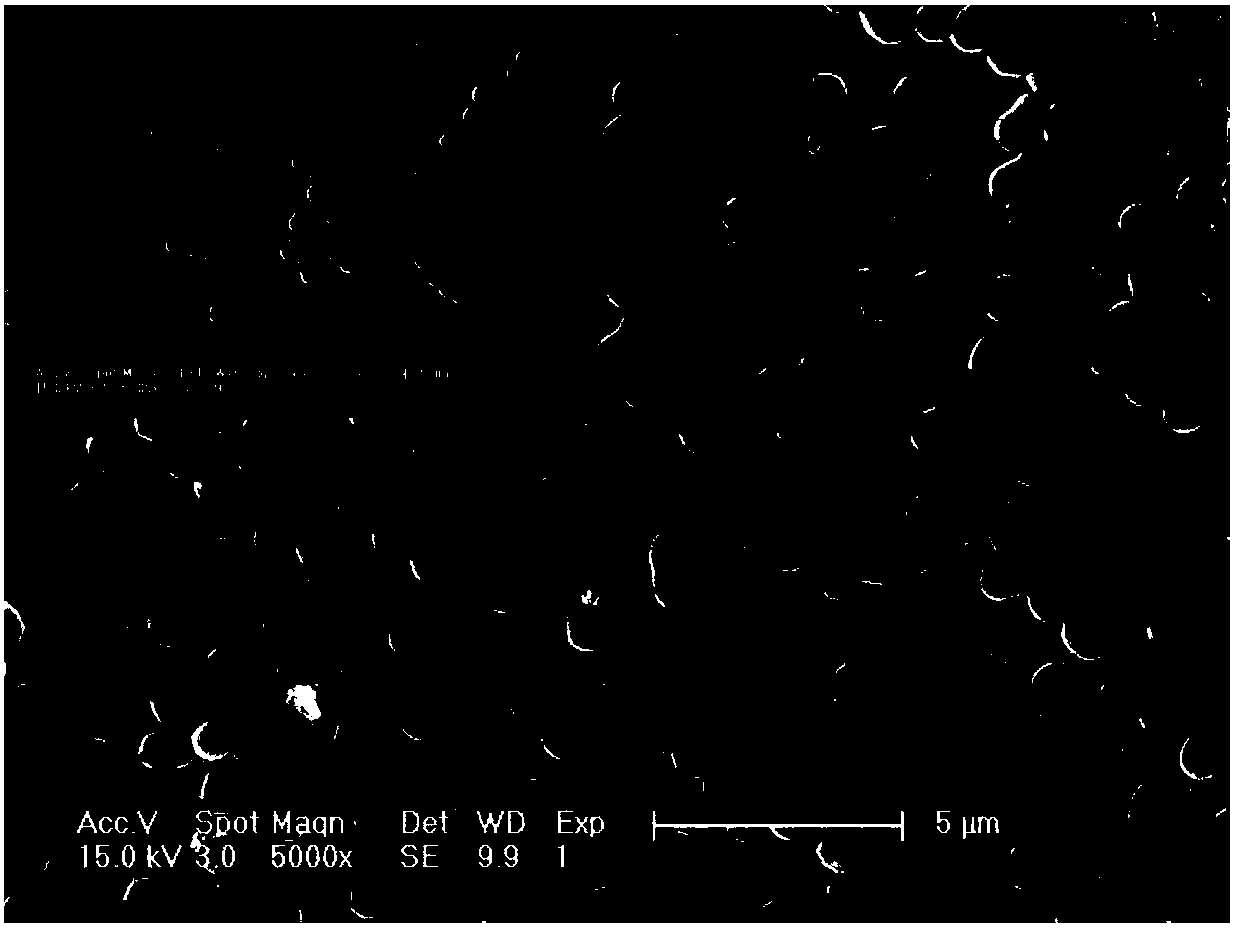

Image

Examples

Embodiment 1

[0031] A preparation method for immobilized microorganisms embedded in airgel, which comprises the steps of:

[0032] S1: Mix the monomers hydroxyethyl methacrylate, N-methylolacrylamide, polyacrylamide and diisodecyl adipate in a molar ratio of 1:3:2:1, and then mix the monomers with water The liquid is mixed evenly according to the volume ratio of 1:7;

[0033]S2: Add 0.5mL (1L of mixed solution) of tetramethylethylenediamine to the above-mentioned mixed solution as a catalyst, and then add 0.5g (1L of mixed solution) of persulfuric acid after magnetic stirring in an ice-water bath environment Ammonium was used as an initiator to react for 8h;

[0034] S3: Freeze the reacted gel in the refrigerator for 12 hours, gradually lower the temperature from -40°C to -80°C in four stages, each stage lowers the temperature by 10°C, and the time interval for changing the temperature between each stage is 3h , and finally lyophilized in a lyophilizer for 24 hours to make hydroxyethyl m...

Embodiment 2

[0041] A preparation method for immobilized microorganisms embedded in airgel, which comprises the steps of:

[0042] S1: Mix the monomers hydroxyethyl methacrylate, N-methylol acrylamide, polyacrylamide and diisodecyl adipate in a molar ratio of 2:3:3:1, and then mix the monomers with water The liquid is mixed evenly according to the volume ratio of 2:5;

[0043] S2: Add 0.6mL (1L of mixed solution) of tetramethylethylenediamine to the above-mentioned mixed solution as a catalyst, and then add 0.6g (1L of mixed solution) of persulfuric acid after magnetic stirring in an ice-water bath environment Ammonium was used as an initiator to react for 8h;

[0044] S3: Freeze the reacted gel in the refrigerator for 24 hours, gradually lower the temperature from -40°C to -80°C in four stages, each stage lowers the temperature by 10°C, and the time interval for changing the temperature between each stage is 6h , and finally lyophilized in a lyophilizer for 72 hours to make hydroxyethyl...

Embodiment 3

[0051] A preparation method for immobilized microorganisms embedded in airgel, which comprises the steps of:

[0052] S1: Mix the monomers hydroxyethyl methacrylate, N-methylol acrylamide, polyacrylamide and diisodecyl adipate in a molar ratio of 3:17:4:2, and then mix the monomers with water The liquid is mixed evenly according to the volume ratio of 2:9;

[0053] S2: Add 0.8mL (1L of mixed solution) of tetramethylethylenediamine to the above-mentioned mixed solution as a catalyst, and then add 1g (1L of mixed solution) of ammonium persulfate after magnetic stirring in an ice-water bath environment As an initiator to react for 9h;

[0054] S3: Freeze the reacted gel in the refrigerator for 24 hours, gradually lower the temperature from -40°C to -80°C in four stages, each stage lowers the temperature by 10°C, and the time interval for changing the temperature between each stage is 6h , and finally lyophilized in a lyophilizer for 36 hours to make hydroxyethyl methacrylate-hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com