Method and application of preparing high-level oxidation catalyst through cobalt ore smelting slag

An advanced oxidation and catalyst technology, applied in the field of solid waste recycling, to overcome easy loss, improve oxidation efficiency, and the process is simple and controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] At 25°C, take 20g of 200-mesh cobalt ore smelting slag, stir in 100ml of 0.01mol / L hydrochloric acid solution for 1h, filter, and collect the filter cake. Disperse the filter cake with 50ml of distilled water, slowly add 1mol / L sodium hydroxide solution dropwise, and react for 0.5h when the pH=9; then continue to dropwise add sodium hydroxide solution to adjust the pH of the reaction solution to 13, and react for 2h at room temperature ; After the reaction solution was left to age for 6h, the filter material was collected and washed with water until neutral. The filter material was dried in a vacuum oven at 60° C. for 6 hours, and ground to obtain a yellow-brown powder.

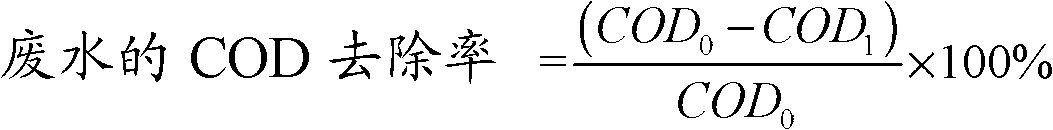

[0033] Add 3 g of the catalyst prepared in this example and 4 g of the oxidizing agent potassium monoperoxohydrogensulfate into 100 ml of cobalt concentrate smelting wastewater (COD is 700 mg / L, pH = 8-9), and stir magnetically at 50 ° C for 12 h , the treatment liquid was tested, and the COD removal ...

Embodiment 2

[0035] At 25°C, take 20 g of 350-mesh cobalt ore smelting slag, stir in 20 ml of 0.1 mol / L sulfuric acid solution for 1 hour, filter, and collect the filter cake. Disperse the filter cake with 50ml of distilled water, slowly add 1mol / L sodium hydroxide solution dropwise, and react for 1h when the pH=9; then continue to dropwise add sodium hydroxide solution to adjust the pH of the reaction solution to 13, and react for 6h at room temperature; After the reaction solution was left to age for 20 h, the solid phase was collected and washed with water until neutral. The slag was simply dried and placed in a vacuum dryer, dried at 60° C. for 4 hours, and then ground to obtain a brown-yellow powder.

[0036] Add 3 g of the catalyst prepared in this example and 4 g of the oxidizing agent potassium monoperoxohydrogensulfate into 100 ml of cobalt concentrate smelting wastewater (adjust the pH of the water sample to 3 with 1M sulfuric acid in advance), and stir magnetically at 50°C for 1...

Embodiment 3

[0038] At 25°C, take 20 g of 350-mesh cobalt ore smelting slag, stir in 100 ml of 0.01 mol / L sulfuric acid solution for 4 hours, filter, and collect the filter cake. Disperse the filter cake with 100ml of distilled water, then slowly add 1mol / L sodium hydroxide solution dropwise, when the pH=9, react for 1h; then continue to dropwise add sodium hydroxide solution to adjust the pH of the reaction solution to 13, and react for 4h at room temperature ; After the reaction solution was left to age for 6h, the solid phase was collected and washed with water until neutral. The slag was simply dried and then placed in a muffle furnace, heated to 500°C at a rate of 10°C / min, calcined for 4 hours, and ground to obtain a brown-red powder.

[0039] Add 3 g of the catalyst prepared in this example and 4 g of the oxidizing agent potassium monoperoxohydrogensulfate into 100 ml of cobalt concentrate smelting wastewater (adjust the pH of the water sample to 3 with 1M sulfuric acid in advance),...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com