Glass powder enhanced Zr modification montmorillonite honeycomb block chromium sorbent and preparation method thereof

A montmorillonite and glass powder technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of powder loss, difficult separation, no porous structure, etc., and achieve easy separation and adsorption. Good effect, good for adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

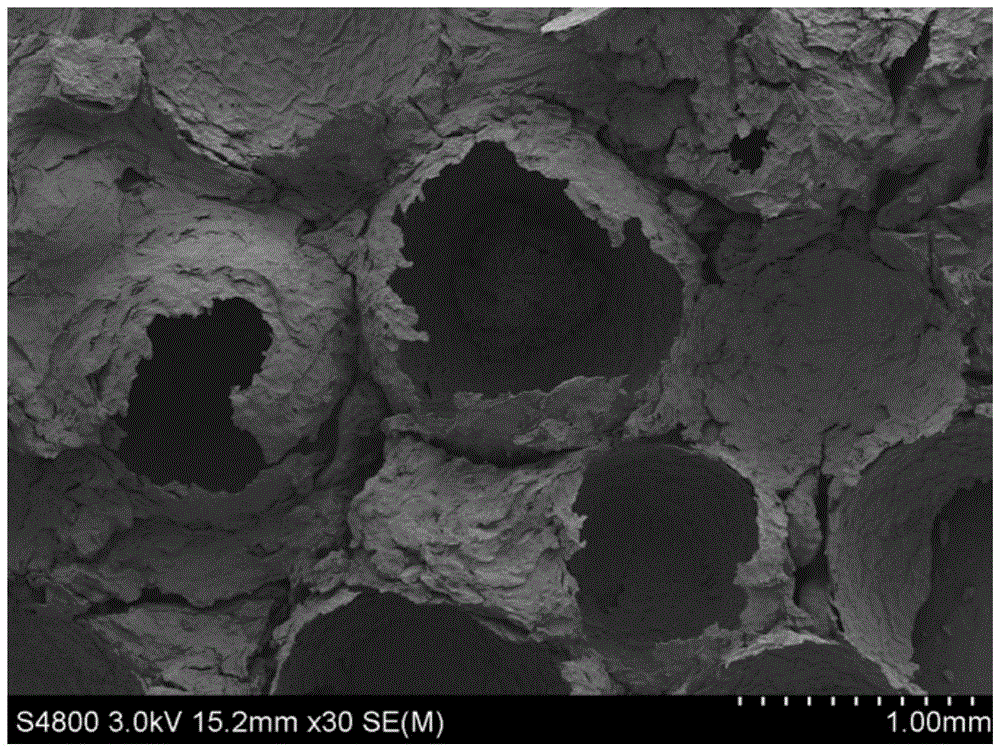

Image

Examples

Embodiment 1

[0042] 1) Take a montmorillonite suspension that is uniformly dispersed and has a mass concentration of 10%.

[0043] 2) Stir at high speed at 40°C, add the zirconium sulfate solution dropwise to the montmorillonite suspension, the mass ratio of zirconium sulfate to montmorillonite is 1:5, continue stirring for 1 hour after the addition, and use 1mol / L The pH value of the sodium hydroxide solution was adjusted to 3, soaked for 7 hours, centrifuged, and the centrifuged filter cake was taken out and placed in a beaker.

[0044] 3) Dry the filter cake at 80°C, grind it through a 200-mesh sieve after drying, and roast at 400°C for 3 hours to obtain Zr-MMT powder.

[0045] 4) Dissolve 12.5g of monomer acrylamide (AM) and 1.25g of cross-linking agent N,N'-methylenebisacrylamide (MBAM) in 15mL of water, add 1.25mL of dispersant polyacrylate ammonium salt after dissolving, Stir evenly to obtain a mixed solution, at this time A:R:S:T=12.5:1.25:1.25:15.

[0046] 5) Slowly add 5 g of t...

Embodiment 2

[0054] 1) Take a montmorillonite suspension that is uniformly dispersed and has a mass concentration of 10%.

[0055] 2) Stir at high speed at 60°C, drop the zirconium sulfate solution into the montmorillonite suspension, the mass ratio of zirconium sulfate to montmorillonite is 2:5, continue to stir for 1h after the dropwise addition, and use 1mol / L The pH value of the sodium hydroxide solution was adjusted to 7, centrifuged after 8 hours of immersion, and the centrifuged filter cake was taken out and placed in a beaker.

[0056] 3) Dry the filter cake at 80°C, grind it through a 200-mesh sieve after drying, and roast at 500°C for 3 hours to obtain Zr-MMT powder.

[0057] 4) Dissolve 11.5g of monomer acrylamide (AM) and 1.35g of cross-linking agent N,N'-methylenebisacrylamide (MBAM) in 15mL of water, add 1.35mL of dispersant polyacrylate ammonium salt after dissolving, Stir evenly to obtain a mixed solution, at this time A:R:S:T=11.5:1.35:1.35:15.

[0058] 5) Slowly add 3 g...

Embodiment 3

[0065] 1) Take a montmorillonite suspension that is uniformly dispersed and has a mass concentration of 10%.

[0066] 2) Stir at high speed at 80°C, drop the zirconium sulfate solution into the montmorillonite suspension, the mass ratio of zirconium sulfate to montmorillonite is 1.2:5, continue to stir for 1h after the dropwise addition, and use 1mol / L The sodium hydroxide solution adjusted the pH value to 2, centrifuged after soaking for 6 hours, and took out the centrifuged filter cake and placed it in a beaker.

[0067] 3) Dry the filter cake at 80°C, grind it through a 200-mesh sieve after drying, and roast at 500°C for 3 hours to obtain Zr-MMT powder.

[0068] 4) Dissolve 13.5g of monomer acrylamide (AM) and 1.15g of cross-linking agent N,N'-methylenebisacrylamide (MBAM) in 15mL of water, add 1.25mL of dispersant ammonium citrate after dissolving, and stir Evenly, a mixed solution is obtained, at this time A:R:S:T=13.5:1.15:1.25:15.

[0069] 5) Slowly add 4 g of the Zr-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com