Porous carbon load noble metal catalyst and preparation method thereof

A precious metal catalyst, porous carbon technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of easy loss of nano-active centers, poor catalyst stability, use Life shortening and other problems, to achieve uniform morphology, stable performance, and improve the effect of affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

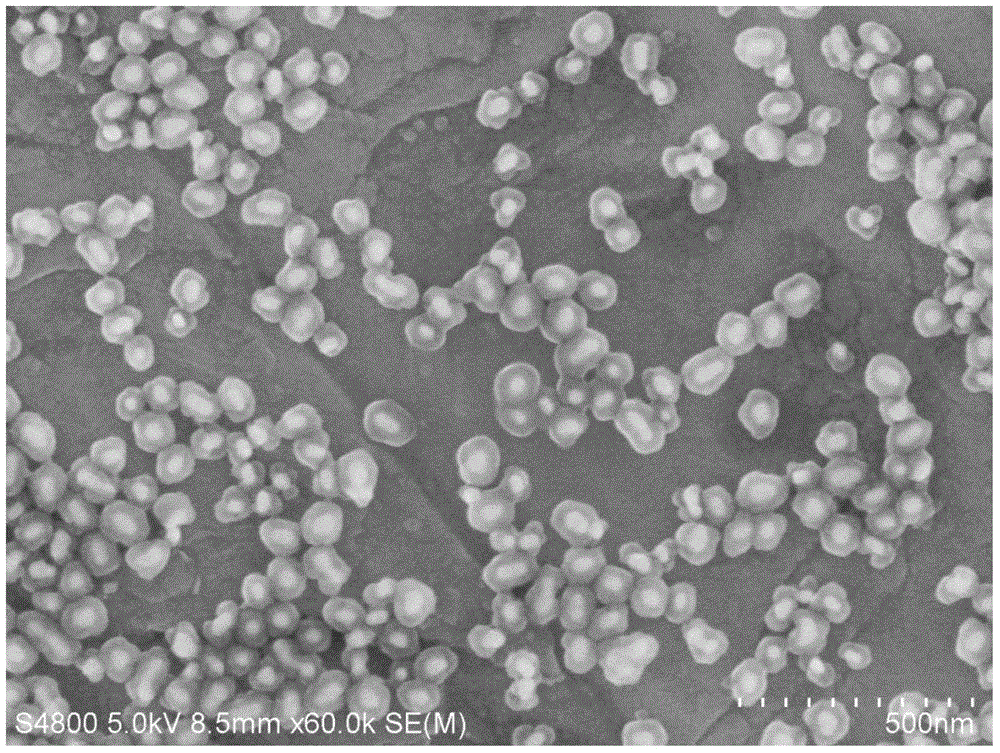

[0030] Place a three-necked flask containing 100mL of chloroauric acid aqueous solution (0.1g / L) in an oil bath at 100°C, and after uniformly heating up, add 1.4mL of sodium citrate aqueous solution (0.113g / mL) dropwise, and add dropwise after 12 minutes 1.4 mL of the above-mentioned sodium citrate solution was reacted for 1 hour, and then the heating was stopped and the temperature was lowered to room temperature to obtain a dispersion liquid containing gold nanoparticles. Add 3mL PVP aqueous solution (9.28wt%) in the obtained dispersion liquid, after stirring for 2 days, centrifuge at 10000r / min rotating speed for 30min, add deionized water after absorbing the supernatant, repeat the above-mentioned centrifugal washing step 2 times after ultrasonic dispersion for 5min, Surface-modified gold nanoparticles were obtained.

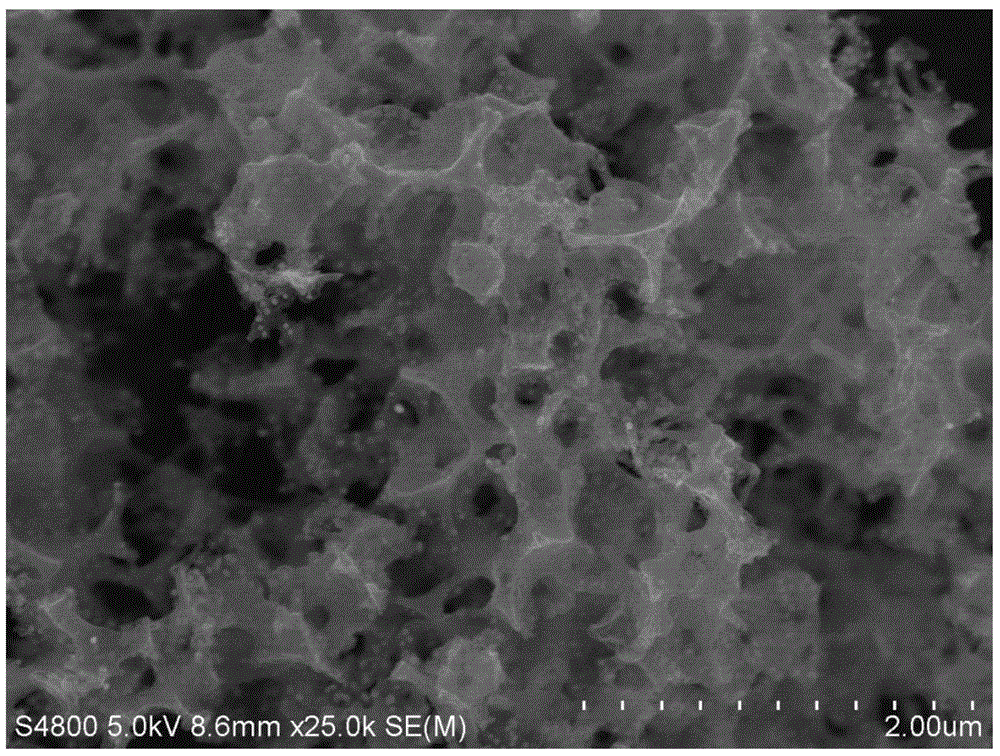

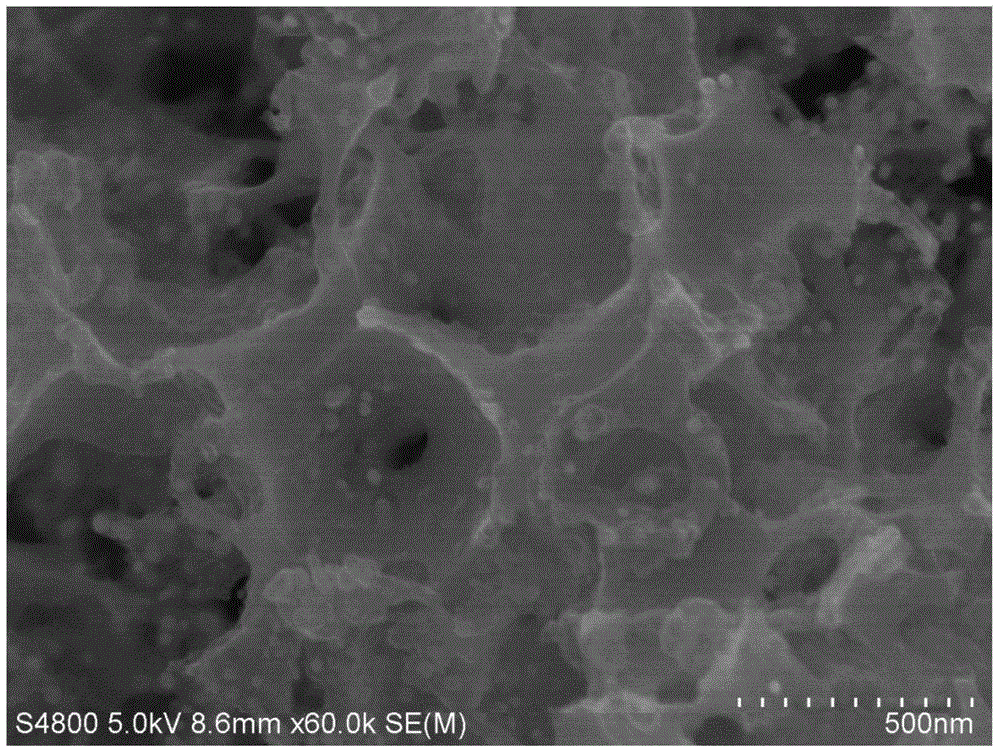

[0031] Mix 0.01 g of the above-mentioned surface-modified gold nanoparticles with 10 mL of absolute ethanol and 0.4 mL of deionized water and disperse ultra...

Embodiment 2

[0035] Place a three-necked flask containing 100mL of chloroauric acid aqueous solution (0.1g / L) in an oil bath at 100°C, and after uniformly heating up, add 1.6mL of sodium citrate aqueous solution (0.113g / mL) dropwise, and add dropwise after 12 minutes 1.6 mL of the above-mentioned sodium citrate solution was reacted for 1 h, and then the heating was stopped and the temperature was lowered to room temperature to obtain a dispersion liquid containing gold nanoparticles. Add 2.5mL PVP aqueous solution (9wt%) to the obtained dispersion, after stirring for 2 days, centrifuge at 10000r / min for 30min, add deionized water after absorbing the supernatant, and repeat the above centrifugal washing step 2 times after ultrasonic dispersion for 5min. Surface-modified gold nanoparticles were obtained.

[0036] Mix 0.01 g of the surface-modified gold nanoparticles obtained above with 10 mL of absolute ethanol and 0.4 mL of deionized water and disperse ultrasonically for 10 min to form a ho...

Embodiment 3

[0040] Place a three-necked flask containing 100mL of chloroauric acid aqueous solution (0.1g / L) in an oil bath at 105°C, and after uniform heating, add 1.6mL of sodium citrate aqueous solution (0.113g / mL) dropwise, and add dropwise after 12 minutes 1.6 mL of the above-mentioned sodium citrate solution was reacted for 1 h, and then the heating was stopped and the temperature was lowered to room temperature to obtain a dispersion liquid containing gold nanoparticles. Add 3 mL of PVP aqueous solution (10wt%) to the resulting dispersion, stir for 2 days, centrifuge at 12,000 r / min for 30 min, add deionized water after absorbing the supernatant, and repeat the above-mentioned centrifugal washing step 2 times after ultrasonic dispersion for 5 min to obtain Surface-modified gold nanoparticles.

[0041] Mix 0.01 g of surface-modified gold nanoparticles obtained above with 10 mL of absolute ethanol and 0.4 mL of deionized water and disperse ultrasonically for 10 min to form a homogene...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com