Hydrophilic material-doped blended membrane nanoscale zero-valent iron-loading composite material as well as preparation method and application thereof

A technology of nano-zero-valent iron and hydrophilic materials, applied in the field of preparation and modification of nano-materials, can solve the problems of easily deactivated particles, secondary pollution, easy agglomeration, etc., achieve good application prospects, improve service life, disperse high sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

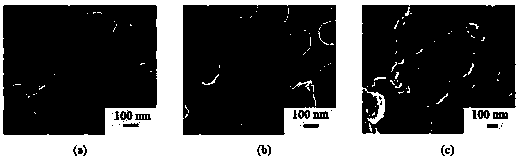

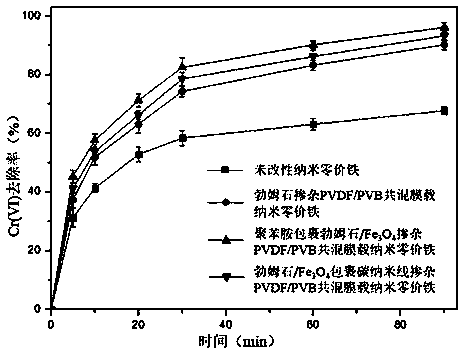

[0035] Example 1: Boehmite-doped PVDF / PVB blend film-loaded nano-zero-valent iron composite material, polyaniline-wrapped boehmite / Fe 3 o 4 Doped PVDF / PVB blend film loaded nano-zero-valent iron composite material, boehmite / Fe 3 o 4 The preparation method of wrapped carbon nanowire doped PVDF / PVB blend film loaded nano-zero-valent iron composite material and its removal of Cr(Ⅵ) in water, the specific content is as follows:

[0036] 1. Preparation of ordinary unmodified nano-sized zero-valent iron particles and its removal effect on Cr(Ⅵ) in water:

[0037] (1) Measure 100 mL of KBH with a concentration of 1 mol / L in a nitrogen-protected environment 4 The solution was added dropwise with 100 mL of FeSO with a concentration of 1 mol / L 4 In the solution, the process is continuously stirred by a magnetic stirrer until the reaction is completed, and the solution after the reaction is passed through a Buchner funnel with a 0.22 micron microporous filter membrane, rinsed with de...

Embodiment 2

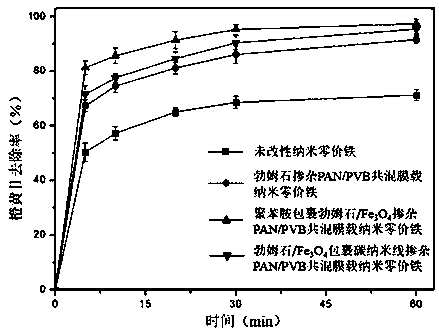

[0053] Example 2: Boehmite-doped PAN / PVB blend film-loaded nano-zero-valent iron composite material, polyaniline-wrapped boehmite / Fe 3 o 4 Doped PAN / PVB blend film loaded nano-zero-valent iron composite material, boehmite / Fe 3 o 4 The preparation method of wrapped carbon nanowire doped PAN / PVB blend film loaded nano-zero-valent iron composite material and its removal of orange yellow II in water, the specific content is as follows:

[0054] 1. Preparation of ordinary unmodified nano-sized zero-valent iron particles and its removal effect on orange II in water:

[0055] (1) Measure 100 mL of KBH with a concentration of 1 mol / L in a nitrogen-protected environment 4 The solution was added dropwise with 100 mL of FeSO with a concentration of 1 mol / L 4 In the solution, the process is continuously stirred by a magnetic stirrer until the reaction is completed, and the solution after the reaction is passed through a Buchner funnel with a 0.22 micron microporous filter membrane, ri...

Embodiment 3

[0070] Example 3: Boehmite-doped PVDF / PVB blend film-loaded nano-zero-valent iron composite material, polyaniline-wrapped boehmite / Fe 3 o 4 Doped PVDF / PVB blend film loaded nano-zero-valent iron composite material, boehmite / Fe 3 o 4 The preparation method of wrapped carbon nanowire doped PVDF / PVB blend film-loaded nano-zero-valent iron composite material and its removal of methyl orange in water, the specific content is as follows:

[0071] 1. Preparation of ordinary unmodified nanometer zero-valent iron particles and its removal effect on methyl orange in water:

[0072] (1) Measure 100 mL of KBH with a concentration of 1 mol / L in a nitrogen-protected environment 4 The solution was added dropwise with 100 mL of FeSO with a concentration of 1 mol / L 4 In the solution, the process is continuously stirred by a magnetic stirrer until the reaction is completed, and the solution after the reaction is passed through a Buchner funnel with a 0.22 micron microporous filter membrane,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com