Carbon-doped TiO2 visible light-responding catalytic film on glass carrier and preparation method thereof

A photocatalytic film and glass sheet technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc. Photocatalytic activity, solving the effect of easy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

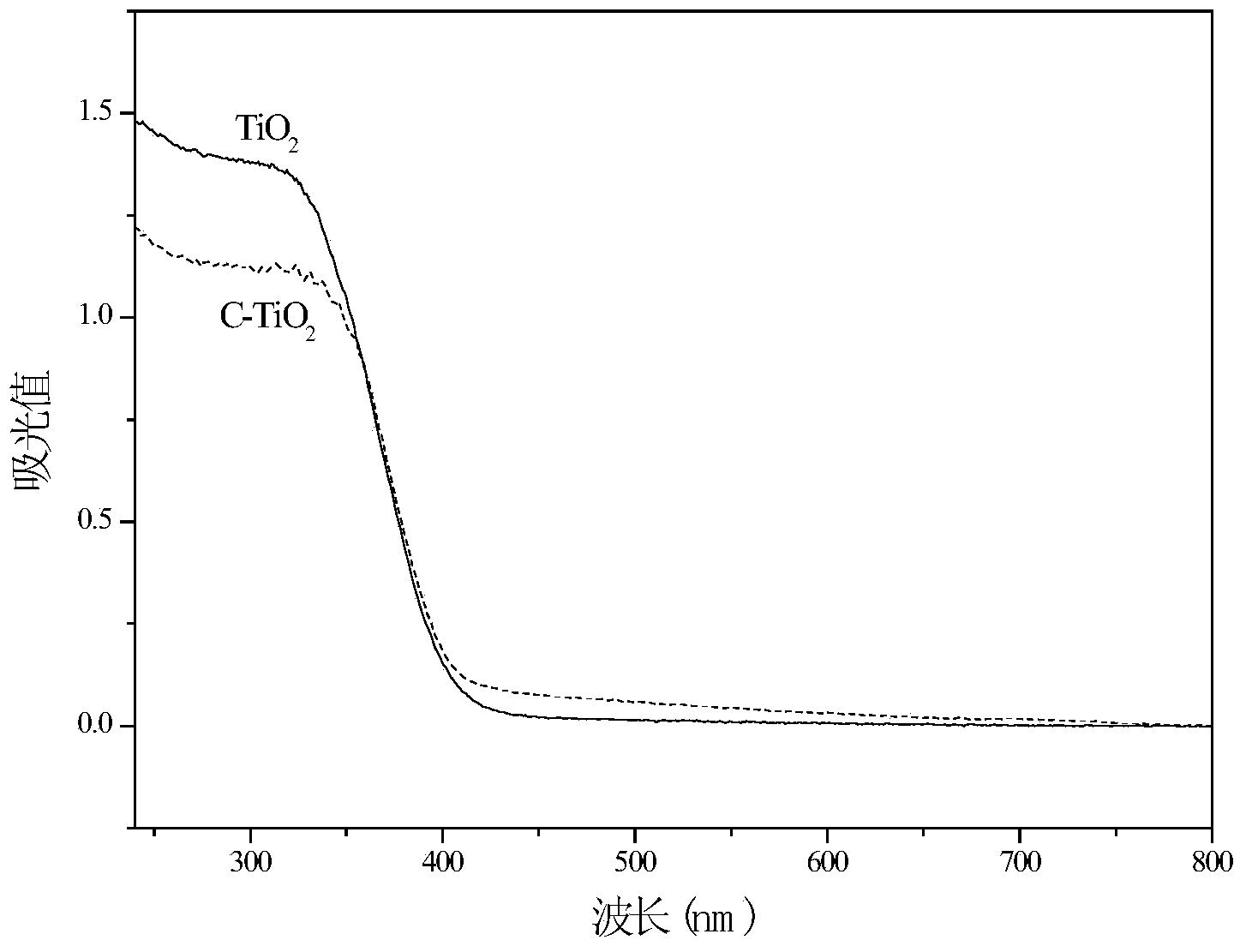

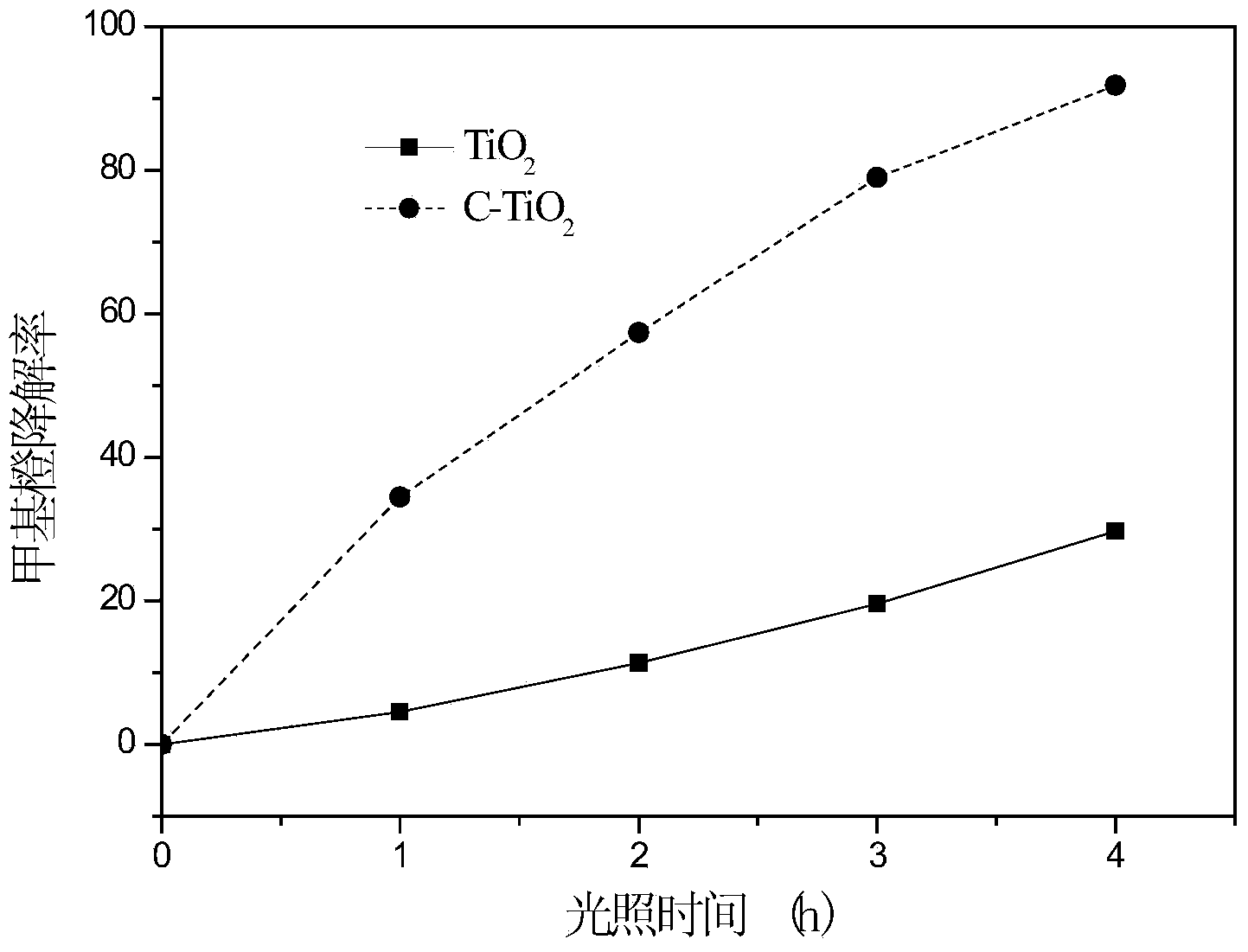

[0024] Carbon-doped TiO on a glass flake carrier 2 Visible light-responsive catalytic membrane, which uses Tween 80 as a template ion and carbon source to prepare non-metallic carbon-doped nano-TiO 2 Photocatalytic thin films, the non-metallic carbon-doped nano-TiO 2 The photocatalytic film is supported on the glass flake carrier, and the non-metallic carbon doped nano-TiO 2 C and TiO in photocatalytic thin films 2 The mass ratio is 0.62:99.38.

[0025] Its preparation method is:

[0026] 1. Non-metallic carbon-doped nano-TiO 2 Preparation of photocatalytic thin film precursor sol:

[0027] Dissolve 10 mL of Tween 80 surfactant in 40 mL of isopropanol and stir. After Tween 80 is completely dissolved, slowly add 6 mL of isopropyl titanate and stir for 5 min. After mixing evenly, add 6 mL of glacial acetic acid, and then increase Magnetic stirring speed, after vigorous stirring for 10 min, the reactor was sealed, stirred and aged at room temperature for 24 h, and a transpa...

Embodiment 2

[0031] Carbon-doped TiO on a glass flake carrier 2 Visible light-responsive catalytic membrane, which uses Tween 80 as a template ion and carbon source to prepare non-metallic carbon-doped nano-TiO 2 Photocatalytic thin films, the non-metallic carbon-doped nano-TiO 2 The photocatalytic film is supported on the glass flake carrier, and the non-metallic carbon doped nano-TiO 2 C and TiO in photocatalytic thin films 2 The mass ratio is 0.49:99.51.

[0032] The preparation method is the same as that of Example 1, except that the amount of Tween 80 used in step 1 is 5 mL.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com