Method for integrated treatment of dyeing wastewater by using magnetic activated carbon

A magnetic activated carbon, printing and dyeing wastewater technology, applied in the field of water treatment, can solve the problems of difficult separation of wastewater, non-regeneration, large amount of mud production, etc., to achieve the effect of improving treatment efficiency, improving treatment capacity and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: A method for the integrated treatment of printing and dyeing wastewater with magnetic activated carbon, in which H 2 o 2 Composition of Fe 3 o 4 -H 2 o 2 The Fenton-like system enables the regeneration of magnetic activated carbon. Magnetic activated carbon is powder activated carbon: PAC and nano-iron oxide: Fe 3 o 4 of composite materials. Fe 3 o 4 The / PAC mass ratio is 2. Magnetic activated carbon is produced by chemical co-precipitation method. 3+ / Fe 2+ (Molar ratio)=2 In the reaction system, powdered activated carbon is used as a carrier to complete the reaction by adding lye medium;

[0025] The Fe 3+ / Fe 2+ (molar ratio)=2 reaction system is FeCl3 / FeSO4 (molar ratio)=2 or FeCl3 / FeCl2 (molar ratio)=2;

[0026] The lye medium is NaOH;

[0027] Powdered activated carbon is PAC.

[0028] The specific steps of the chemical co-precipitation method are:

[0029] a. Dry the PAC in an oven at 100°C for 24 hours;

[0030] b. Mix 400mL of FeC...

Embodiment 2

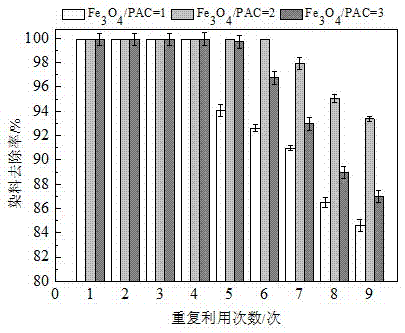

[0034] Example 2: The method of integrated magnetic activated carbon treatment of printing and dyeing wastewater (methylene blue): 1. Under constant temperature conditions, put 500mL of methylene blue wastewater with a certain concentration in a constant temperature water bath for mechanical stirring, and add a certain amount of PAC-Fe 3 o 4 Composite materials, adjust the pH value to the set value, and add the corresponding amount of H at the same time 2 o 2 , Regular sampling, determination of water dye concentration and COD value. 2. At the end of each cycle of experiments, use NdFeB magnets to separate and recover the magnetic activated carbon, and clean the magnetic activated carbon with ultrapure water for the next cycle of reaction. The magnetic activated carbon was recycled and used 9 times, and the COD and dye concentration of the effluent were measured in each cycle.

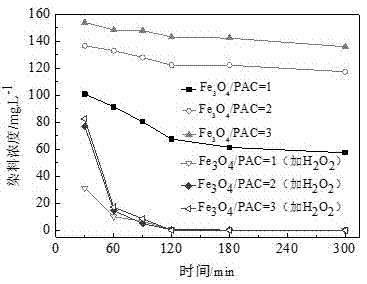

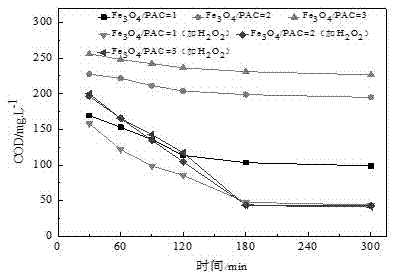

[0035] figure 1 , 2 Indicates that when using PAC-Fe 3 o 4 Synchronous dosing of H in the sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com