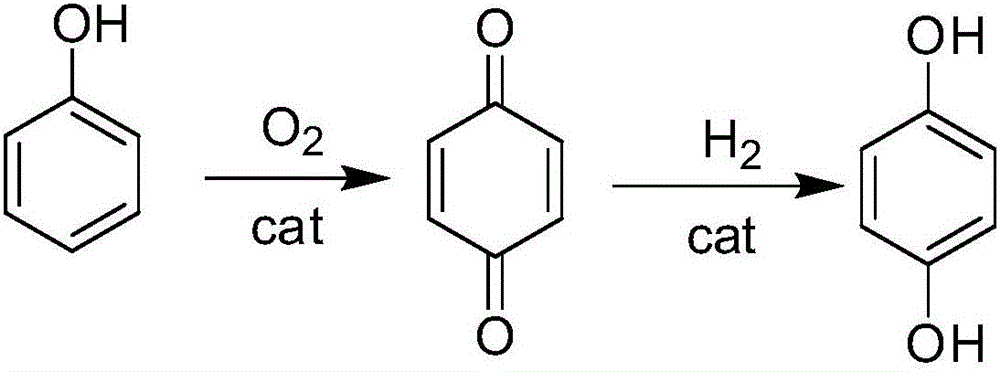

Method for preparing hydroquinone by oxidizing phenol

A technology for hydroquinone and phenol, applied in the field of phenol oxidation to prepare hydroquinone, can solve the problems of complicated separation and low operability, and achieve the effects of reducing separation difficulty and separation loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

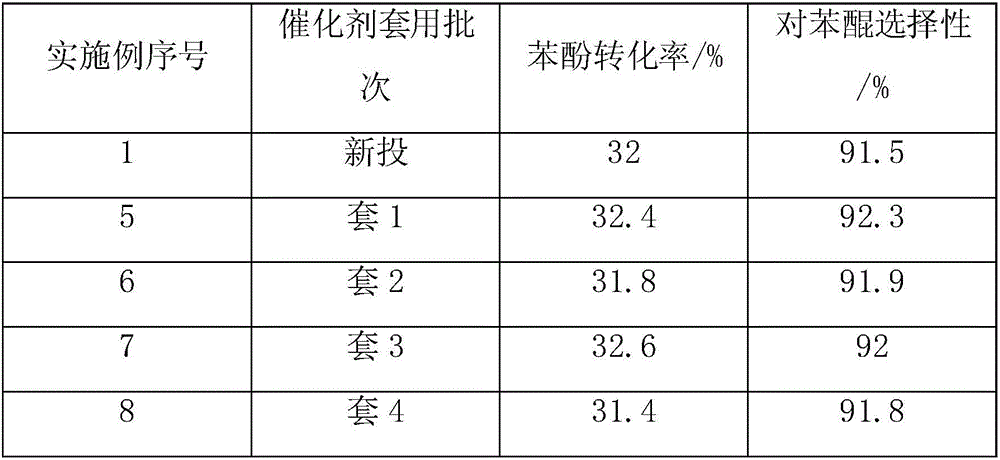

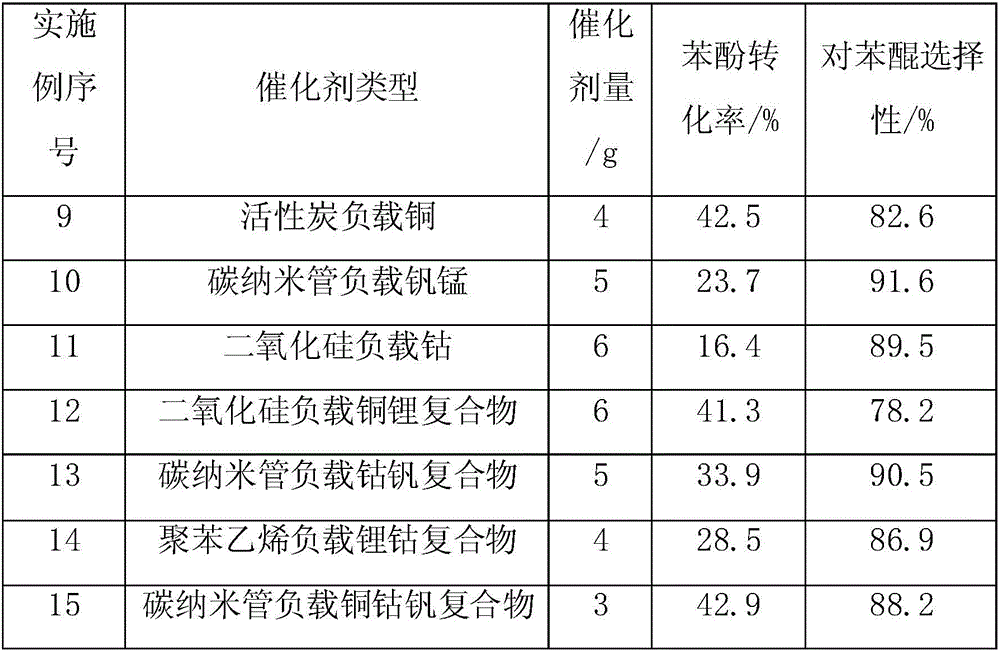

Examples

Embodiment 1

[0021] In order to better illustrate the preparation process of the supported catalyst, take the copper-cobalt catalyst supported by carbon nanotubes used in Example 1 as an example (for other catalyst preparation processes, refer to the aforementioned related patents), introduce its preparation process: 4mmol six Cobalt nitrate hydrate and 8 mmol copper nitrate trihydrate were dissolved in 60 ml DMF, and then 4 mmol trimesic acid and 2 mmol 4,4-bipyridine were added to obtain a mixed solution. The above mixed solution was transferred to an autoclave, the reaction temperature was 80°C, and the temperature was kept for 72 hours. After the heat preservation, it was naturally cooled to room temperature, and the generated crystals were washed with 30ml of DMF three times, and dried for 12 hours under a vacuum degree of -0.1MPa to obtain cobalt-copper Metal organic framework product CuCo-MOF. The obtained CuCo-MOF was calcined in a tube furnace at 600° C. for 3 hours under an argon...

Embodiment 2

[0024] Add 80g of phenol, 300g of dichloroethane, and 6g of activated carbon-supported cobalt catalyst into a 1L oxidation kettle. After sealing the kettle, 2.5MPa oxygen is introduced, and the temperature is raised to 65°C for 1.5 hours of heat preservation. Cool down and dismantle the kettle, filter out the catalyst, and obtain 378g of oxidizing solution. Analytical results: the conversion rate of phenol is 22%, and the selectivity to p-benzoquinone is 82.7%. Put 378g of oxidizing solution and 2g of 3% Pd / C catalyst into a 1L hydrogenation kettle, seal the kettle and feed 1.0MPa hydrogen gas, raise the temperature to 70°C and keep it warm for 3 hours, cool down and dismantle the kettle, filter out the hydrogenation catalyst, and obtain hydrogenation liquid. Analysis results: the conversion rate of p-benzoquinone is 99.5%, and the selectivity of hydroquinone is 95.4%. The hydrogenation solution first removes dichloroethane under normal pressure, and then carries out negativ...

Embodiment 3

[0026] Add 80g of phenol, 340g of acetic acid, and 6g of polystyrene-supported vanadium-cobalt catalyst into a 1L oxidation kettle. After sealing the kettle, 2.5MPa oxygen is introduced, and the temperature is raised to 80°C for 2 hours. Cool down and disassemble the kettle, filter out the catalyst, and obtain 415g of oxidizing solution. Analytical results: the conversion rate of phenol is 15.8%, and the selectivity to p-benzoquinone is 91.2%. Put 415g of oxidizing solution and 2g of 2% Pt / C catalyst into a 1L hydrogenation kettle, seal the kettle and feed 1.5MPa hydrogen, raise the temperature to 75°C and keep it warm for 2.5 hours, lower the temperature and dismantle the kettle, filter out the hydrogenation catalyst, and obtain hydrogenation liquid. Analysis results: the conversion rate of p-benzoquinone is 100%, and the selectivity of hydroquinone is 94.6%. The hydrogenation liquid first desorbs acetic acid under normal pressure, and then carries out negative pressure rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com