Titanium polyester catalyst

A titanium-based polyester and catalyst technology, which is applied in the field of titanium-based polyester catalysts, can solve problems such as multiple side reactions, molecular chain breaks, and affecting the viscosity of polyester slices, and achieve a good hue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of Catalyst A

[0034] Add 124 grams (0.4 moles) of calcium lactate and 28.4 grams (0.1 moles) of tetraisopropyl titanate into a reactor equipped with a stirrer, a condenser and a thermometer, and drop 12.4 grams (0.4 moles) of ethylene glycol into the reactor. mol), reacted at 70°C for 2 hours, the system was slightly turbid, added 53.2 g (0.2 mol) of tributyl phosphate, and reacted for 1 hour, at this time the system completely changed to a homogeneous clear liquid, and catalyst A was obtained.

[0035] Preparation of polyester

[0036] 500 grams of terephthalic acid and 316 grams of ethylene glycol and catalyst A (based on the amount of polyester produced, the weight of titanium atoms are 5ppm), mixed to form a slurry, added to the polymerization tank, and carried out esterification reaction, The esterification temperature is 230-255°C, the pressure is 0.25MPa, and the water generated by the reaction is discharged through a rectification device. After t...

Embodiment 2

[0040] Preparation of Catalyst B

[0041] Add 74 grams (0.4 moles) of zinc acetate into a reactor equipped with a stirrer, a condenser and a thermometer, then add 28.4 grams (0.1 moles) of tetraisopropyl titanate, and drop 12.4 grams of ethylene glycol into the reactor (0.4 mol), reacted at 70°C for 2 hours, the system was slightly turbid, added 28 g (0.20 mol) of trimethyl phosphate, and reacted for 1 hour, at this time the system completely changed to a homogeneous clear liquid, and catalyst B was obtained.

[0042] Preparation of polyester

[0043] Polyester was prepared by the same method as in Example 1, using Catalyst B as the catalyst (based on the amount of polyester produced) with a titanium atom weight of 5 ppm.

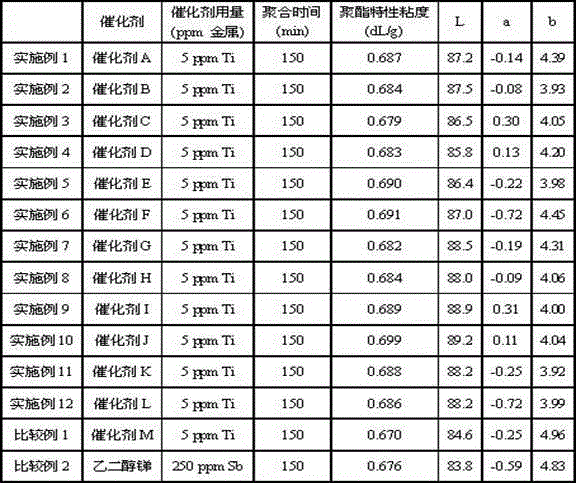

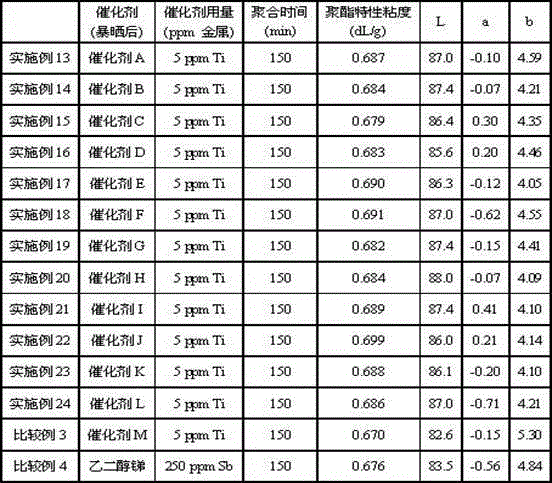

[0044] The test results are shown in Table 1.

[0045]

Embodiment 3

[0047] Preparation of Catalyst C

[0048] Add 103 grams (0.4 moles) of magnesium lactate to a reactor equipped with a stirrer, a condenser and a thermometer, then add 28.4 grams (0.1 moles) of tetraisopropyl titanate, and drop 12.4 grams of ethylene glycol into the reactor (0.4 mol), reacted at 70°C for 2 hours, the system was slightly turbid, added 35 g (0.20 mol) of triethyl phosphate, and reacted for 1 hour, at this time the system completely changed to a homogeneous clear liquid, and catalyst C was obtained.

[0049] Preparation of polyester

[0050] Polyester was prepared by the same method as in Example 1, using Catalyst C as the catalyst (based on the amount of polyester produced) and the weight of titanium atoms was 5 ppm.

[0051] The test results are shown in Table 1.

[0052]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com