Foamed PET (polyethylene glycol terephthalate) plate slice, and preparation method thereof

A technology for slicing and sheeting, applied in the field of foamed PET sheet slicing and its preparation, to achieve the effects of improving melt strength, improving melt strength and intrinsic viscosity, and increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

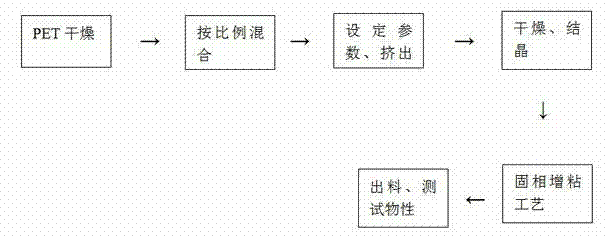

Method used

Image

Examples

Embodiment 1

[0034] 100 parts of PET bottle-grade chips, dried at 140-150°C for 5 hours, the dried PET resin and 0.6 parts of highly active reactive group acrylic polyester multi-polymer were mixed in a high-speed mixer for 10 minutes, and then added polyether polyol and 0.1 parts of antioxidants formed from mixtures of phosphites and polybasic hindered phenols are mixed evenly. Extrude at 240-280°C with a twin-screw extruder, pelletize, dry, and pack for later use.

[0035] The dried slices are dried in a crystallization bed at 160-170°C for 2-3 hours, then solid-phase polycondensed in a vacuum drum at 220-240°C and a vacuum degree of 20-50Pa for 4-8 hours, and then packed.

[0036] The extruder temperature setting: 220°C 240°C 260°C 265°C 265°C 270°C 270°C 265°C; Die: 260°C.

Embodiment 2

[0038] 100 parts of PET bottle-grade chips, dried at 130-140°C for 8 hours, mixed the dried PET resin and 0.4 parts of high-activity epoxy resin chain extender in a high-mixer for 10 minutes, and then added polyether polyol and phosphite Mix 0.1 parts each of the antioxidants formed from the mixture of polyvalent hindered phenols and polybasic hindered phenols evenly. Extrude at 250-270°C with a twin-screw extruder, pelletize, dry, and pack for later use.

[0039] The dried slices are dried in a crystallization bed at 150-170°C for 2-3 hours, then subjected to solid-phase polycondensation in a vacuum drum at 220-240°C and a vacuum degree of 20-50 Pa for 4-8 hours, and then packed.

[0040] The extruder temperature setting: 220°C 240°C 260°C 265°C 270°C 270°C 270°C 265°C; Die: 265°C.

Embodiment 3

[0042] 100 parts of PET bottle-grade chips, dried at 130-140°C for 8 hours, mixed the dried PET resin and 0.3 parts of high-activity epoxy resin chain extender in a high-mixer for 10 minutes, and then added polyether polyol and phosphite 0.1 part of antioxidant formed from a mixture of polybasic hindered phenols and mixed evenly. Extrude at 250-270°C with a twin-screw extruder, pelletize, dry, and pack for later use.

[0043] The dried slices are dried in a crystallization bed at 150-170°C for 2-3 hours, then subjected to solid-phase polycondensation in a vacuum drum at 220-240°C and a vacuum degree of 20-50 Pa for 4-8 hours, and then packed.

[0044] The extruder temperature setting: 220°C 240°C 260°C 265°C 270°C 270°C 270°C 265°C; Die: 260°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com