Long-carbon-chain semi-aromatic nylon PA14T and preparation method thereof

A semi-aromatic, long carbon chain technology, applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of long synthesis route and continuous production difficulties, and achieve high molecular weight, low price and raw material source. rich effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

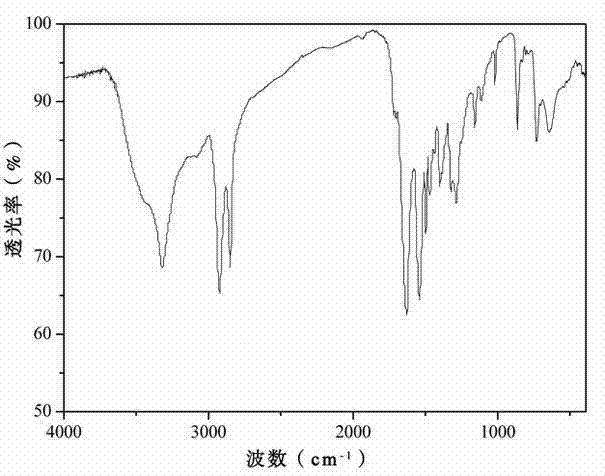

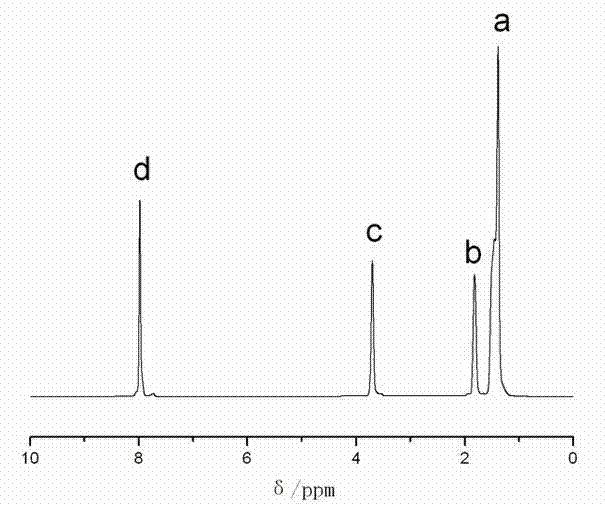

Image

Examples

Embodiment 1

[0028] A kind of long carbon chain semi-aromatic nylon PA14T, its preparation method is:

[0029] (1) Add 1,14-tetradecanediamine into water and heat to 85°C. After the tetradecanediamine is completely dissolved, add 1,4-terephthalic acid to react under stirring. The reaction time After 2 hours, the pH value of the solution was stable at 7.1, and then cooled to room temperature, suction filtered and dried to obtain the PA14T salt in the form of white powder. Wherein, the mass ratio of 1,14-tetradecanediamine to water is 1:10, and the molar ratio of 1,14-tetradecanediamine to 1,4-terephthalic acid is 1:1.05.

[0030] (2) Add the prepared PA14T salt and absolute ethanol into a stainless steel polymerization kettle at a solid-to-liquid ratio of 1:1 by mass. After replacing the air in the kettle with carbon dioxide for 3 times, the system pressure is 0.3MPa. Stir for 2 hours Gradually heat up to 200°C, control the pressure in the kettle to 1.5 MPa, keep the pressure for 2 hours, ...

Embodiment 2

[0037] Embodiment 2 comparative test

[0038] A kind of long carbon chain semi-aromatic nylon PA14T, its preparation method is:

[0039] (1) The preparation method is the same as step (1) in Example 1;

[0040] (2) Add the prepared PA14T salt and absolute ethanol into a stainless steel polymerization kettle at a solid-to-liquid ratio of 1:1 by mass, replace the air in the kettle with carbon dioxide for 3 times, and gradually heat up to 200 °C within 2 hours under stirring. ℃, control the pressure in the kettle to 1.5 MPa, keep the pressure for 2 hours, then slowly release the gas to make the pressure in the kettle drop to normal pressure within 2 hours, then raise the temperature to 230℃, continue the reaction for 3 hours, and obtain a light yellow powder The semi-aromatic nylon PA14T has a melting point of 297°C. The intrinsic viscosity is 1.63 dL / g, and its physical and mechanical properties are tested, and the results are listed in Table 2.

[0041] Table 2 The physica...

Embodiment 3

[0045] A kind of long carbon chain semi-aromatic nylon PA14T, its preparation method is:

[0046] (1) Add 1,14-tetradecanediamine into water and heat to 90°C. After the tetradecanediamine is completely dissolved, add 1,4-terephthalic acid to react under stirring. The reaction time After 2 hours, the pH value of the solution was stable at 7.2, then cooled to room temperature, suction filtered and dried to obtain white powder PA14T salt. Wherein, the mass ratio of 1,14-tetradecanediamine to water is 1:8, and the molar ratio of 1,14-tetradecanediamine to 1,4-terephthalic acid is 1:1.02.

[0047] (2) Add the prepared PA14T salt and absolute ethanol into the stainless steel polymerization kettle according to the mass ratio of 1:1.5, replace the air in the kettle with carbon dioxide for 3 times, the system pressure is 0.3MPa, and gradually heat up within 2 hours under stirring To 215°C, control the pressure inside the kettle to 1.5 MPa, keep the pressure for 3 hours, then slowly re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com