Unsaturated polyester resin for polyester concrete and preparation method of unsaturated polyester resin

A polyester concrete and polyester resin technology, applied in the chemical industry, can solve the problems of long post-curing time, low reactivity, and high cost, and achieve the effects of shortening the curing time, increasing the molecular weight, and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

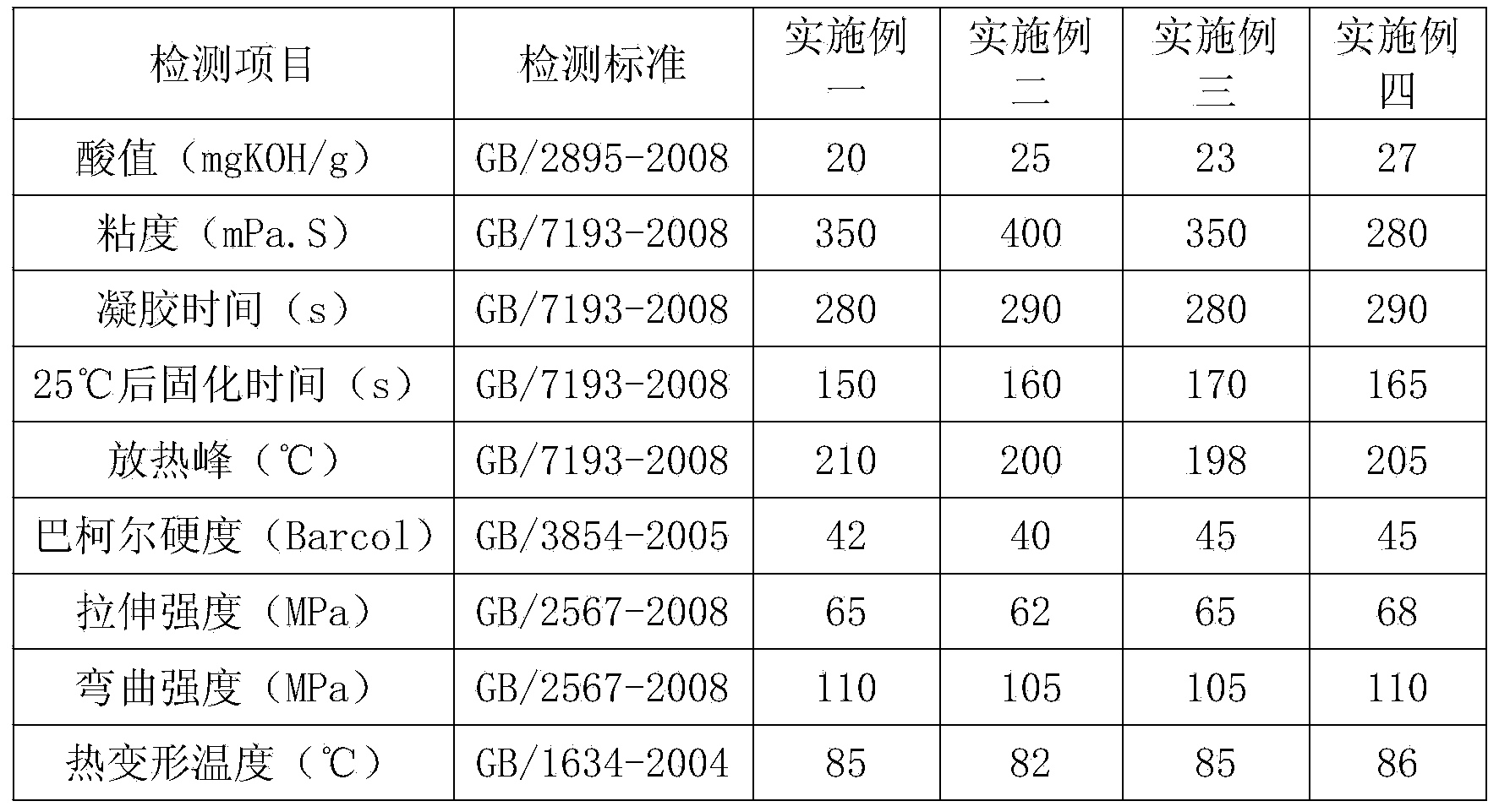

Examples

Embodiment 1

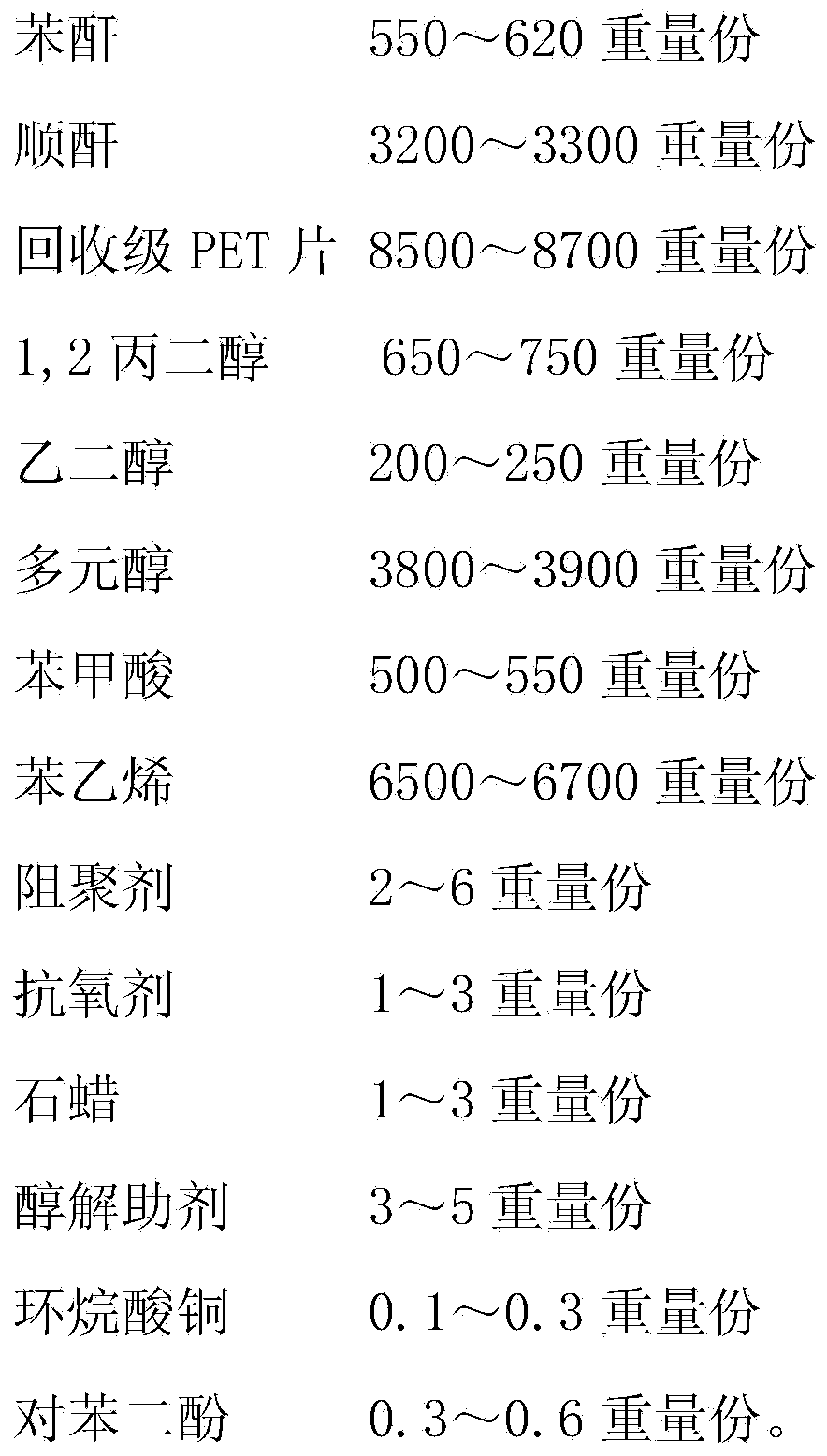

[0024] The preparation formula of the polyester concrete unsaturated polyester resin of present embodiment one is:

[0025] 550 parts by weight of phthalic anhydride, 8500 parts by weight of recycled PET flakes, 3300 parts by weight of maleic anhydride, 500 parts by weight of benzoic acid, 750 parts by weight of 1,2 propylene glycol, 200 parts by weight of ethylene glycol, 3800 parts by weight of polyol, 6500 parts by weight of styrene part, 2 parts by weight of polymerization inhibitor, 3 parts by weight of antioxidant, 2 parts by weight of paraffin, 3 parts by weight of alcoholysis aid, 0.1 part by weight of copper naphthenate, 0.5 part by weight of hydroquinone.

[0026] In Example 1, the recycled grade PET flakes are obtained by pulverizing discarded pure PET beverage bottle flakes; the polymerization inhibitor is 2 parts by weight of p-benzoquinone; the antioxidant is 3 parts by weight of triphosphite Phenyl ester; the alcoholysis aid is 3 parts by weight of stannous chlo...

Embodiment 2

[0033] The preparation formula of the polyester concrete unsaturated polyester resin of present embodiment two is:

[0034] 580 parts by weight of phthalic anhydride, 8600 parts by weight of recycled PET flakes, 3250 parts by weight of maleic anhydride, 520 parts by weight of benzoic acid, 700 parts by weight of 1,2 propylene glycol, 230 parts by weight of ethylene glycol, 3850 parts by weight of polyol, 6500 parts by weight of styrene part, 4 parts by weight of a polymerization inhibitor, 1 part by weight of an antioxidant, 2 parts by weight of paraffin, 4 parts by weight of an alcoholysis aid, 0.3 parts by weight of copper naphthenate, and 0.3 parts by weight of hydroquinone.

[0035] In embodiment two, the recycled grade PET flakes are obtained by pulverizing discarded pure PET beverage bottle flakes; the polymerization inhibitor is 2 parts by weight of p-benzoquinone and 2 parts by weight of hydroquinone; the antioxidant is The triphenyl phosphite of 1 weight part; Describ...

Embodiment 3

[0042] The preparation formula of the polyester concrete unsaturated polyester resin of present embodiment three is:

[0043] 600 parts by weight of phthalic anhydride, 8600 parts by weight of recycled PET flakes, 3250 parts by weight of maleic anhydride, 520 parts by weight of benzoic acid, 750 parts by weight of 1,2 propylene glycol, 230 parts by weight of ethylene glycol, 3800 parts by weight of polyol, 6600 parts by weight of styrene part, 4 parts by weight of polymerization inhibitor, 2 parts by weight of antioxidant, 1 part by weight of paraffin, 4 parts by weight of alcoholysis aid, 0.2 part by weight of copper naphthenate, 0.5 part by weight of hydroquinone.

[0044] In embodiment three, the recycled grade PET flakes are obtained by pulverizing discarded pure PET beverage bottle flakes; the polymerization inhibitor is 4 parts by weight of hydroquinone; the antioxidant is 2 parts by weight of triphenyl phosphite ester; the alcoholysis aid is 3 parts by weight of zinc ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bending strength | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com