Cheap dicyclopentadiene modified unsaturated polyester resin and preparation method thereof

A technology of dicyclopentadiene and polyester resin, applied in polyester coatings, coatings, etc., can solve the problems that resins do not have relevant properties and cannot be used in synthetic paints, and achieve low price, no peeling, and good fullness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

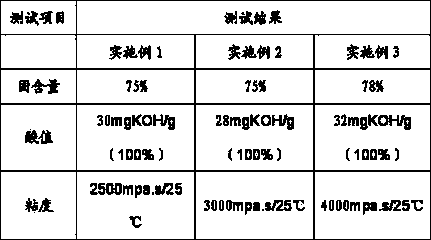

Examples

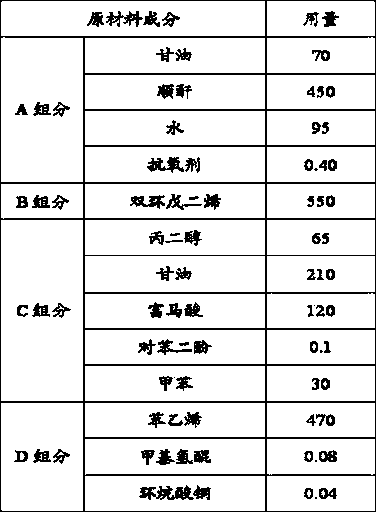

Embodiment 1

[0026]

[0027] The process steps are as follows:

[0028] (1) Put component A (glycerin 70, maleic anhydride 450, water 95, antioxidant 0.40) into the reactor, heat up to 80°C, stop heating, naturally heat up to 105°C, and keep constant temperature;

[0029] (2) Put component B (dicyclopentadiene 550) into the high-level tank, and drop it into the reaction kettle within 2 hours. After the titration, raise the temperature to 120°C and keep it warm for 2.5 hours;

[0030] (3) Add component C (propylene glycol 65, glycerin 210, fumaric acid 120, hydroquinone 0.1, toluene 30) into the reaction kettle, after adding, heat up to reflux temperature 130°C and keep warm for 0.5 hours;

[0031] (4) Slowly raise the temperature to 190°C within 2 hours, keep the constant temperature until the acid value≦35mgKOH / g (100%), and cool down to 120°C when the viscosity is 12s;

[0032] (5) Put in component D (styrene 470, methyl hydroquinone 0.08, copper naphthenate 0.04), and dilute to comp...

Embodiment 2

[0034]

[0035] The process steps are as follows:

[0036] (1) Put component A (glycerin 75, maleic anhydride 420, water 95, antioxidant 0.50) into the reactor, heat up to 80°C, stop heating, naturally heat up to 108°C, and keep constant temperature;

[0037] (2) Put component B (dicyclopentadiene 555) into the high-level tank, and drop it into the reaction kettle within 2 hours. After the titration, raise the temperature to 120°C and keep it warm for 2.5 hours;

[0038] (3) Add component C (propylene glycol 70, glycerin 210, fumaric acid 120, hydroquinone 0.10, toluene 30) into the reaction kettle, after adding, heat up to reflux temperature 130°C and keep warm for 0.5 hours;

[0039] (4) Slowly raise the temperature to 190°C within 2 hours, keep the constant temperature until the acid value≦35mgKOH / g (100%), and cool down to 120°C when the viscosity is 12s;

[0040] (5) Put in component D (styrene 470, methyl hydroquinone 0.08, copper naphthenate 0.04), and dilute to com...

Embodiment 3

[0042]

[0043] The process steps are as follows:

[0044] (1) Put component A (glycerin 80, maleic anhydride 400, water 95, antioxidant 0.60) into the reactor, heat up to 80°C, stop heating, naturally heat up to 110°C, and keep constant temperature;

[0045](2) Put component B (dicyclopentadiene 560) into the high-level tank, and drop it into the reaction kettle within 2 hours. After the titration, raise the temperature to 120°C and keep it warm for 2.5 hours;

[0046] (3) Add component C (propylene glycol 75, glycerin 210, fumaric acid 130, hydroquinone 0.10, toluene 35) into the reaction kettle, after adding, heat up to reflux temperature 130°C, and keep warm for 0.5 hours;

[0047] (4) Slowly raise the temperature to 190°C within 2 hours, keep the constant temperature until the acid value≦35mgKOH / g (100%), and cool down to 120°C when the viscosity is 12s;

[0048] (5) Put in component D (styrene 480, methyl hydroquinone 0.08, copper naphthenate 0.04), and dilute to com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com