Processing technology for antiseptic and antibacterial furniture board

A technology of anti-corrosion, anti-bacterial and processing technology, which is applied in the direction of wood processing equipment, wood treatment, impregnated wood, etc., can solve the problems of cumbersome processing and no processing technology for furniture boards, and achieve simple operation, good anti-corrosion and anti-bacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

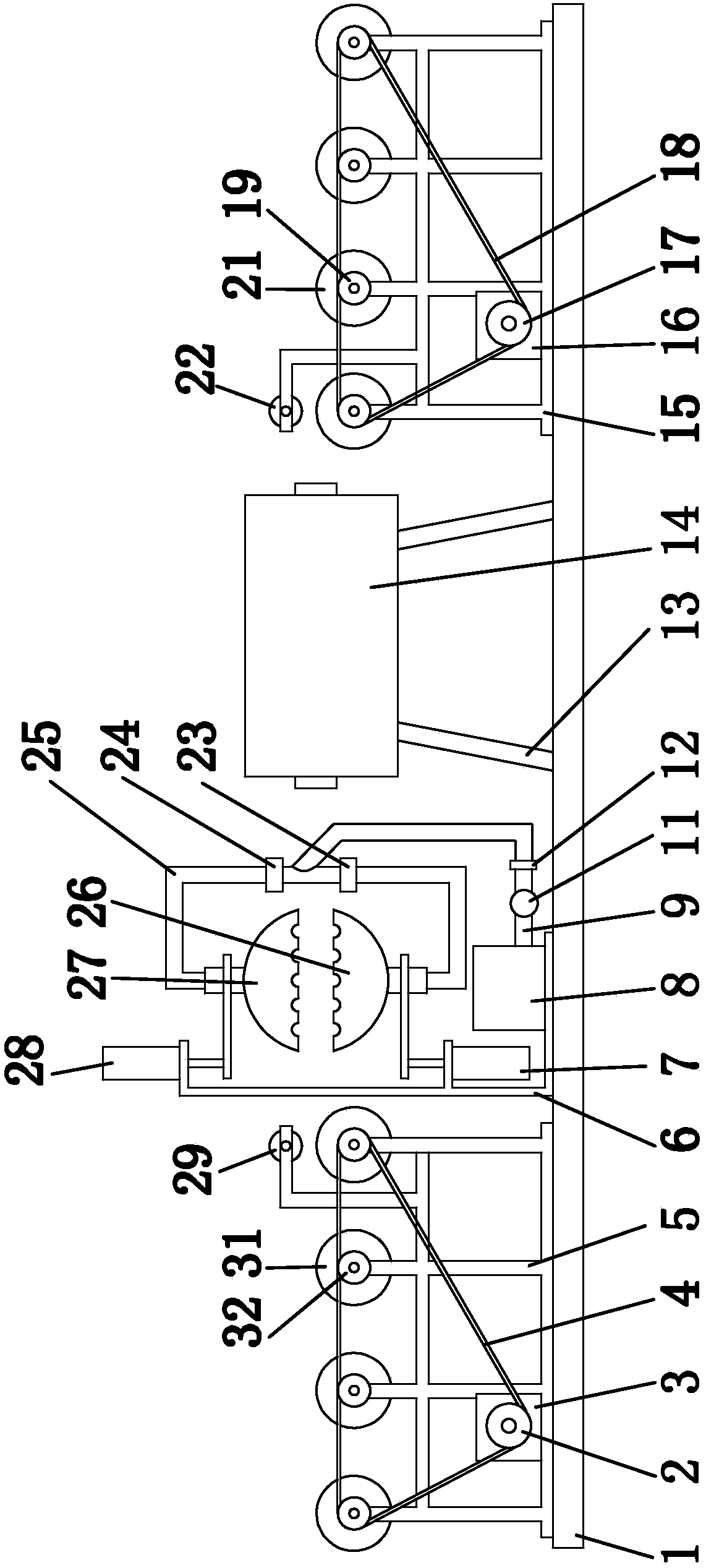

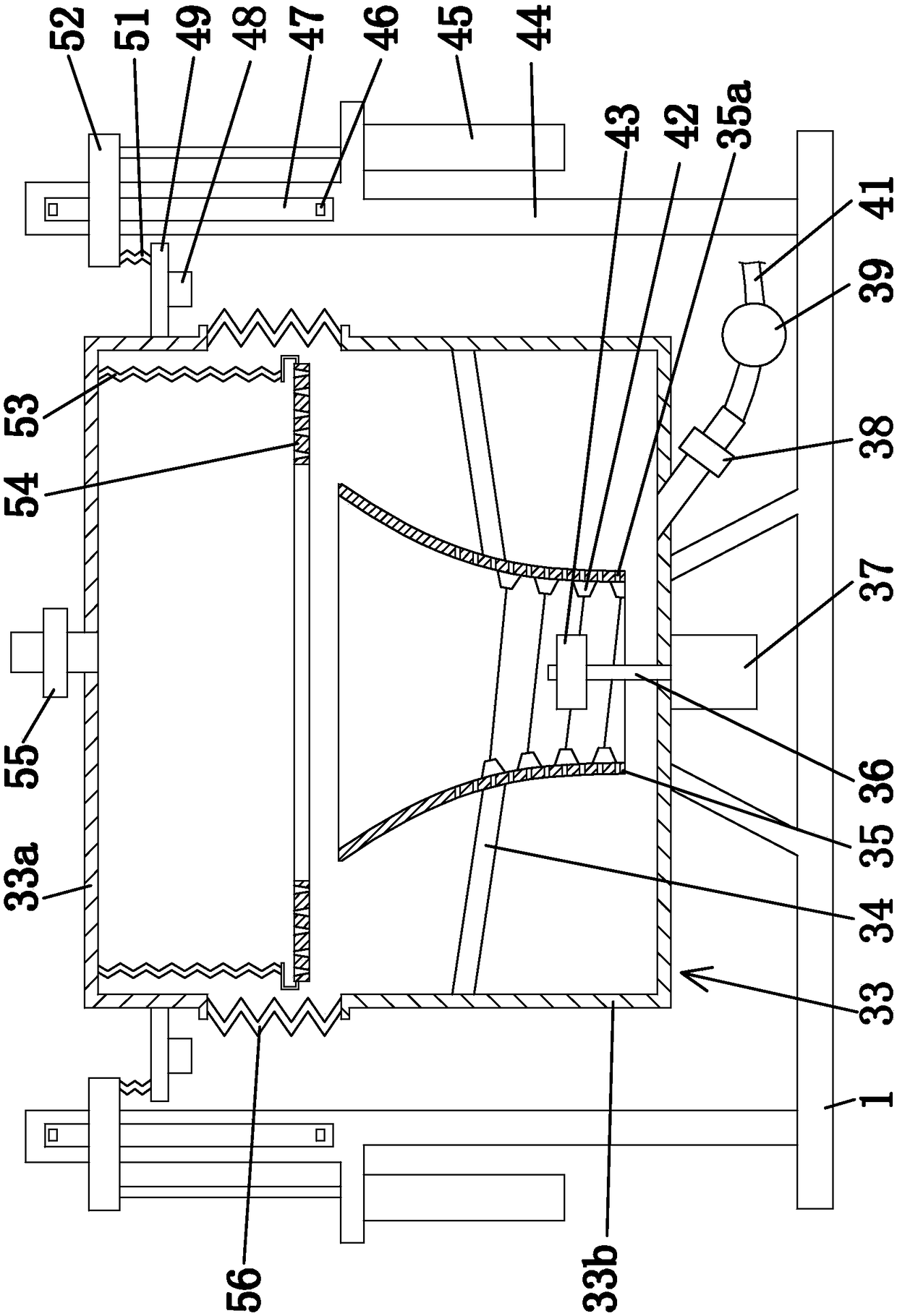

[0042] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0043] The processing technology of this antiseptic and antibacterial furniture board, this technology comprises the following steps:

[0044] a. Drying the board until the moisture content is 12-16%; in this embodiment, drying the board until the moisture content is 13%;

[0045] b. Put the plate into a closed pressure impregnation tank, and inject the following preservatives in parts by weight into the tank: 8-12 parts of emulsifier, 4-10 parts of copper naphthenate, 1-3 parts of diatomaceous earth, 2-5 parts of lignin, 4-8 parts of calcium propionate, 1-3 parts of titanium diboride, 1-4 parts of sodium benzoate, 4-8 parts of acetic acid, 1-3 parts of tributyl phosphate, 2 parts of pyrithione -3 parts and 20-30 parts of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com