Organic-silicon heat-resistant paint

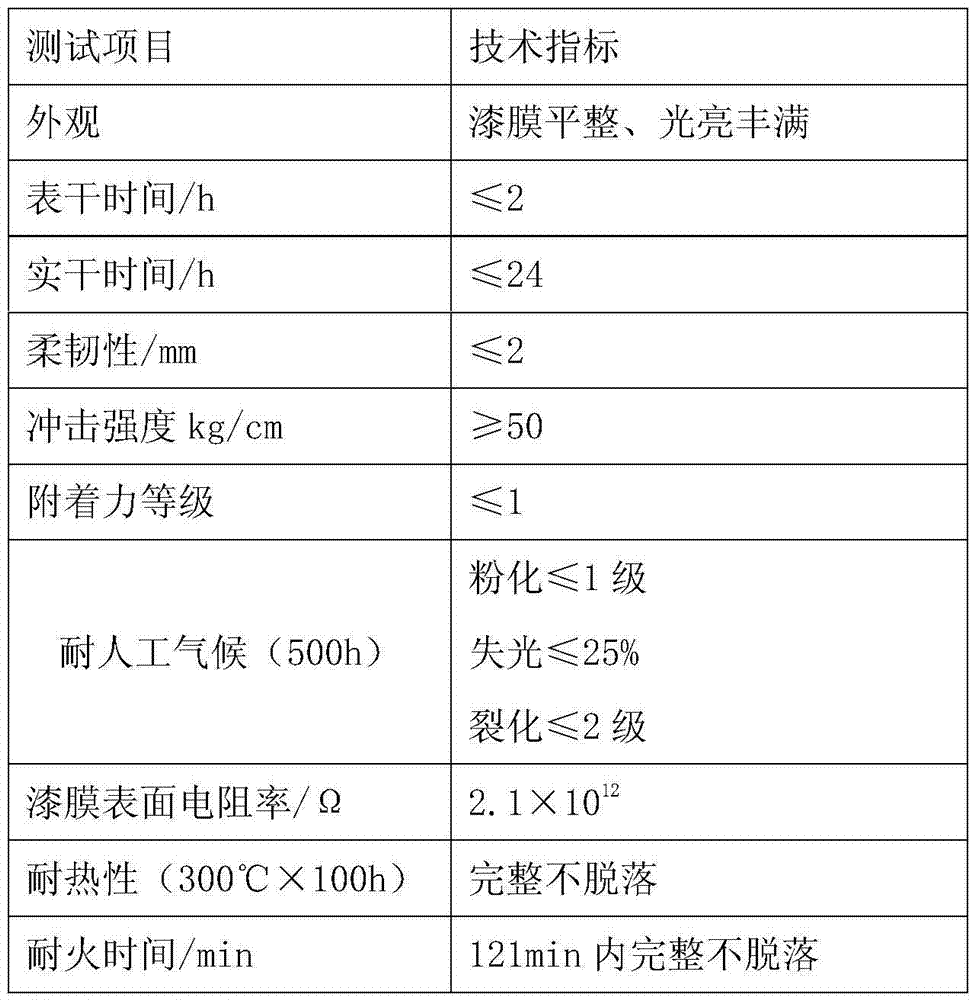

A technology of silicone and heat-resistant paint, applied in the field of paint, can solve the problems of easy peeling, corrosion, heavy odor, etc., and achieve the effect of good insulation performance, improved mechanical properties, and fast drying of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] The paint of this embodiment is made of the following raw materials in parts by weight: 34 parts by weight of silicone resin, 8 mica powder, 3 kaolin, 3 sodium fluorosilicate, 3 copper naphthenate, 2 zinc phosphate, 3 methylhydrogen dichlorosilane, and polytetrahydrofuran Ether diol 2, glycidyl methacrylate 14, dimethylaminopropyl methacrylamide 2, methyl methacrylate 20, acrylic acid 6, titanate coupling agent TMC-TTS3, stearic acid 4 , Crosslinking agent TAC3, isocyanate 2, auxiliary agent 6, xylene 12, butyl acetate 12.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: loess 2, polytetrafluoroethylene powder 5, accelerator DM2, silane coupling agent KH5504, sodium laurate 2, jade 2, salicylic acid 3, phthalate Formate 40, propyl gallate 4, coix seed oil 3, vanadium diboride 2, epicatechin 3; the preparation method is to send loess and jade into a calciner for 3 hours at 720-740°C, and then Take it out, soak in 15% hydrochloric a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com