Efficient cutting gas used for continuous casting and based on coke oven gas

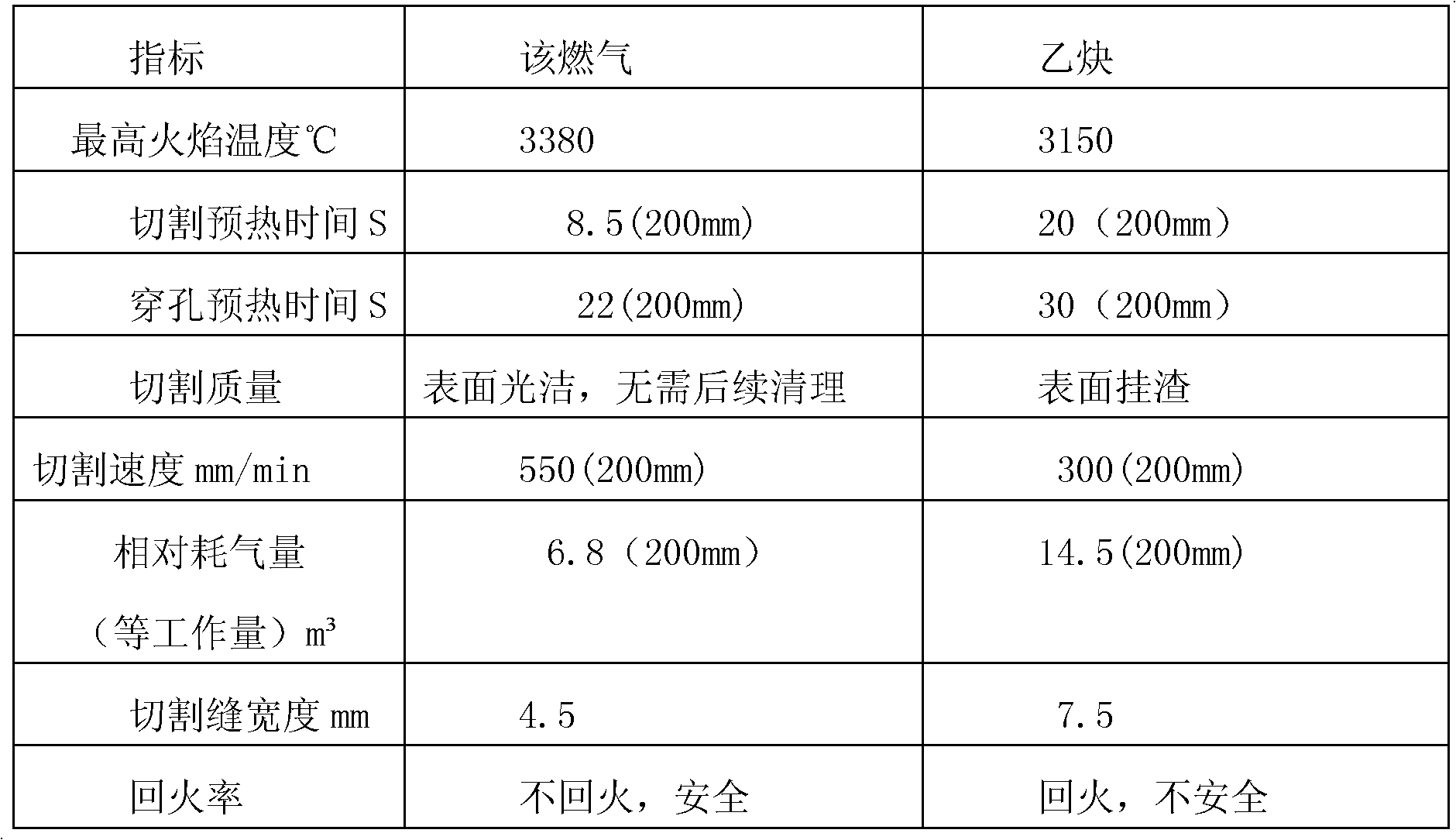

A technology of coke oven gas and continuous casting, which is applied in gas fuel, petroleum industry, fuel and other directions, can solve the problems of poor gas cutting effect, large cutting steel loss and low combustion temperature of coke oven gas, and achieves broad industrialization prospects. Safe to use, high burning temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

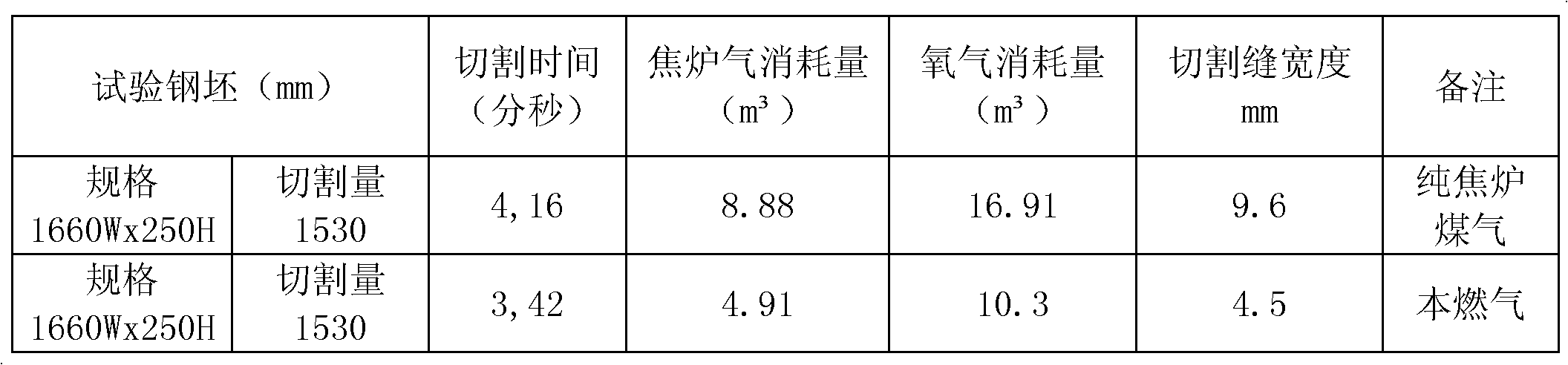

[0026] Embodiment 1 (cold season)

[0027] A high-efficiency continuous casting cutting gas additive liquid formula based on coke oven gas is: copper naphthenate 440mg, methyl butyl ether 320mg, n-hexane 600mg, ferrocene 320mg, methanol 480mg, isooctyl glycolate 240mg, 200mg #Solvent oil 1600mg.

[0028] 1m when cutting 3 Coke oven gas was added with 4mL additive solution.

Embodiment 2

[0029] Embodiment 2 (hot season)

[0030] A high-efficiency continuous casting cutting gas additive liquid formula based on coke oven gas is: copper naphthenate 320mg, methyl butyl ether 280mg, n-hexane 520mg, ferrocene 320mg, methanol 400mg, isooctyl glycolate 240mg, 200mg #Solvent oil 1920mg.

[0031] 1.2m when cutting 3 Coke oven gas was added with 4mL additive solution.

Embodiment 3

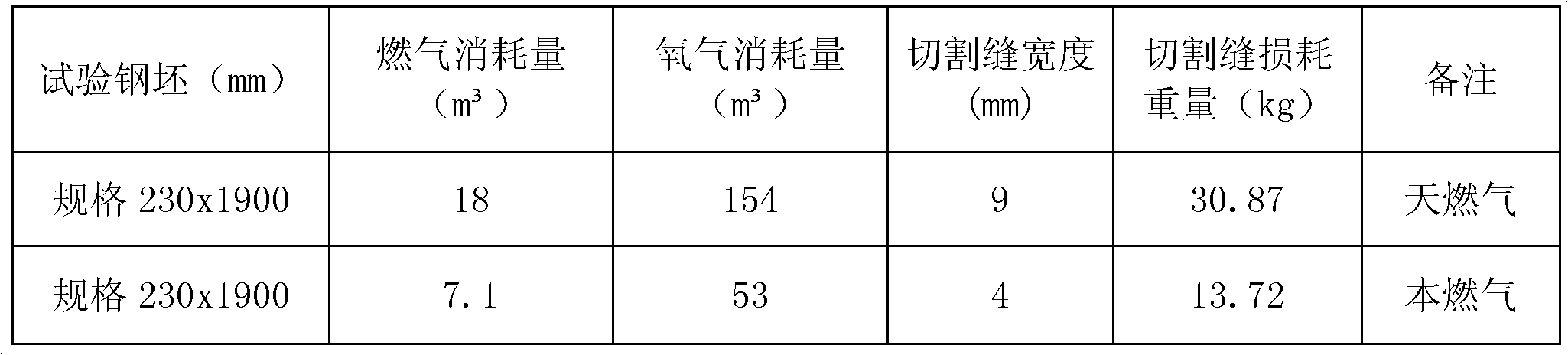

[0032] Embodiment 3 performance test

[0033] The cutting gas that embodiment 1 obtains is carried out gas detection when indoor cutting, and the concentration value of indoor sulfur dioxide, nitrogen dioxide, carbon monoxide is respectively 0.02mg / m in continuous casting cutting process 3 , 0.02mg / m 3 , 0.62mg / m 3 , which is lower than the national "Indoor Air Quality Standard".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com