Amino resin paint for flexible and weather-resistant copper sculpture

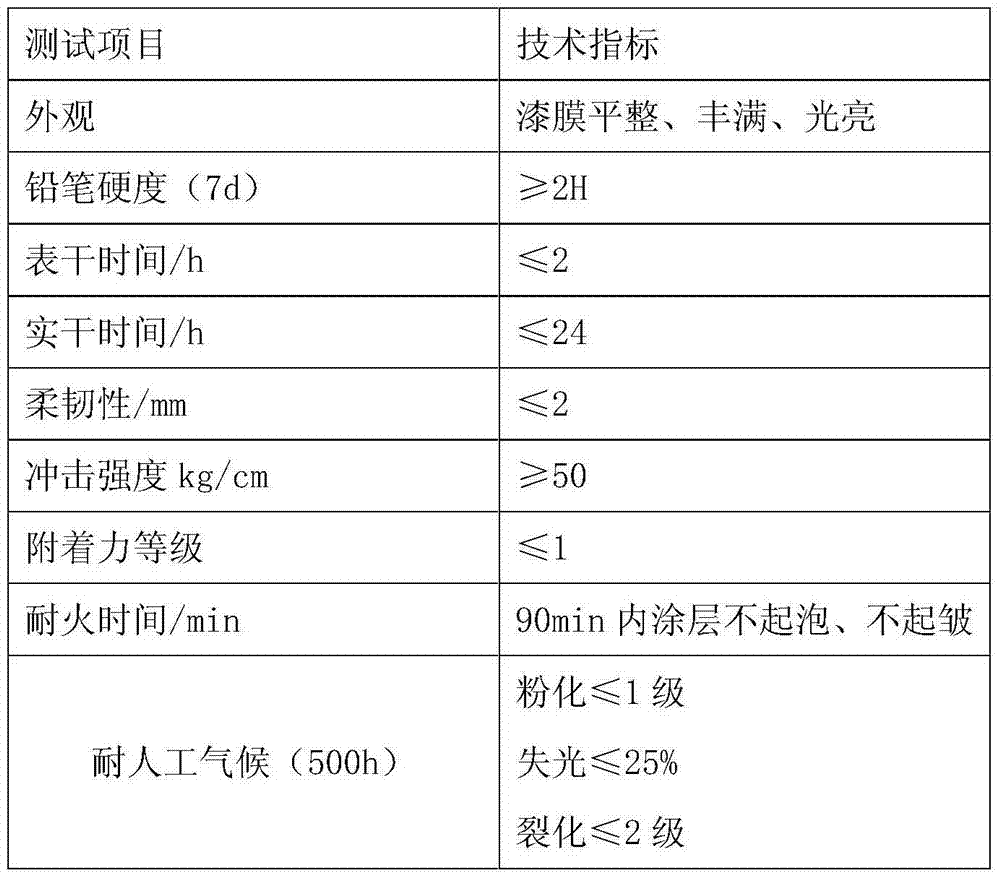

An amino resin, copper sculpture technology, applied in the field of paint, can solve the problems of affecting the appearance and service life, prone to oxidation and corrosion, etc., and achieve the effect of good gloss and fullness of the paint film, safe use and good adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] The paint of this embodiment is made of the following raw materials in parts by weight: amino resin 36, copper naphthenate 3, tetrapropylammonium acetate 2, propylene glycol methyl ether acetate 8, polydimethylsiloxane 4, polyether acrylate 18 , trimethylolpropane triacrylate 24, dibutyl phthalate 8, accelerator DTDM 1.2, silane coupling agent KH-5602.0, semi-reinforcing carbon black 12, diaminodiphenyl sulfone 8, peroxide Dicumene 2, additives 6, xylene 12, butyl acetate 12.

[0013] The auxiliary agent is made of the following raw materials in parts by weight: clay 12, diatomite 4, jade 3, sepiolite 3, accelerator DTDM2, crosslinking agent TAC3, sodium sebacate 2, alkylphenol polyoxygen Vinyl ether 5, sodium tripolyphosphate 2, glycerol triacetate 40, vanadium diboride 2, propyl gallate 2, barley oil 3, epicatechin 2; the preparation method is to mix clay, diatomaceous earth, jade 1. Put the sepiolite into the calcination furnace and calcinate at 700-720°C for 3 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com