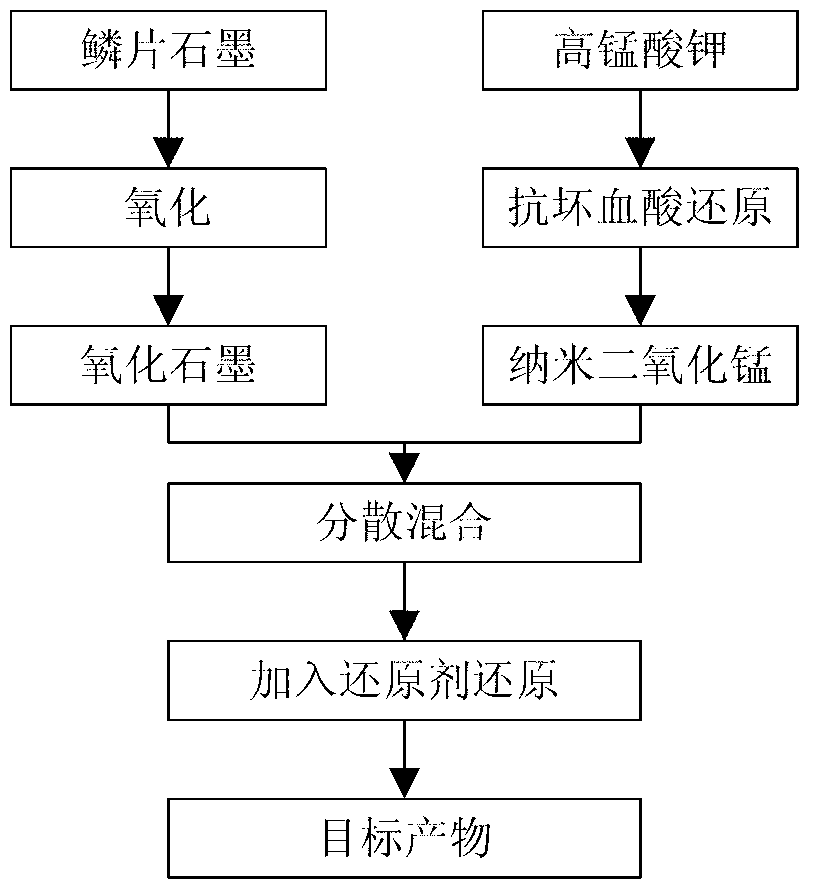

Graphene-cladding manganese dioxide combination electrode material and method for producing same

A technology of graphene coating and manganese dioxide, which is applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, circuits, etc., can solve problems such as unsatisfactory cycle performance, easy agglomeration, and affecting performance, so as to increase cycle Stability, prevent agglomeration, increase the effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

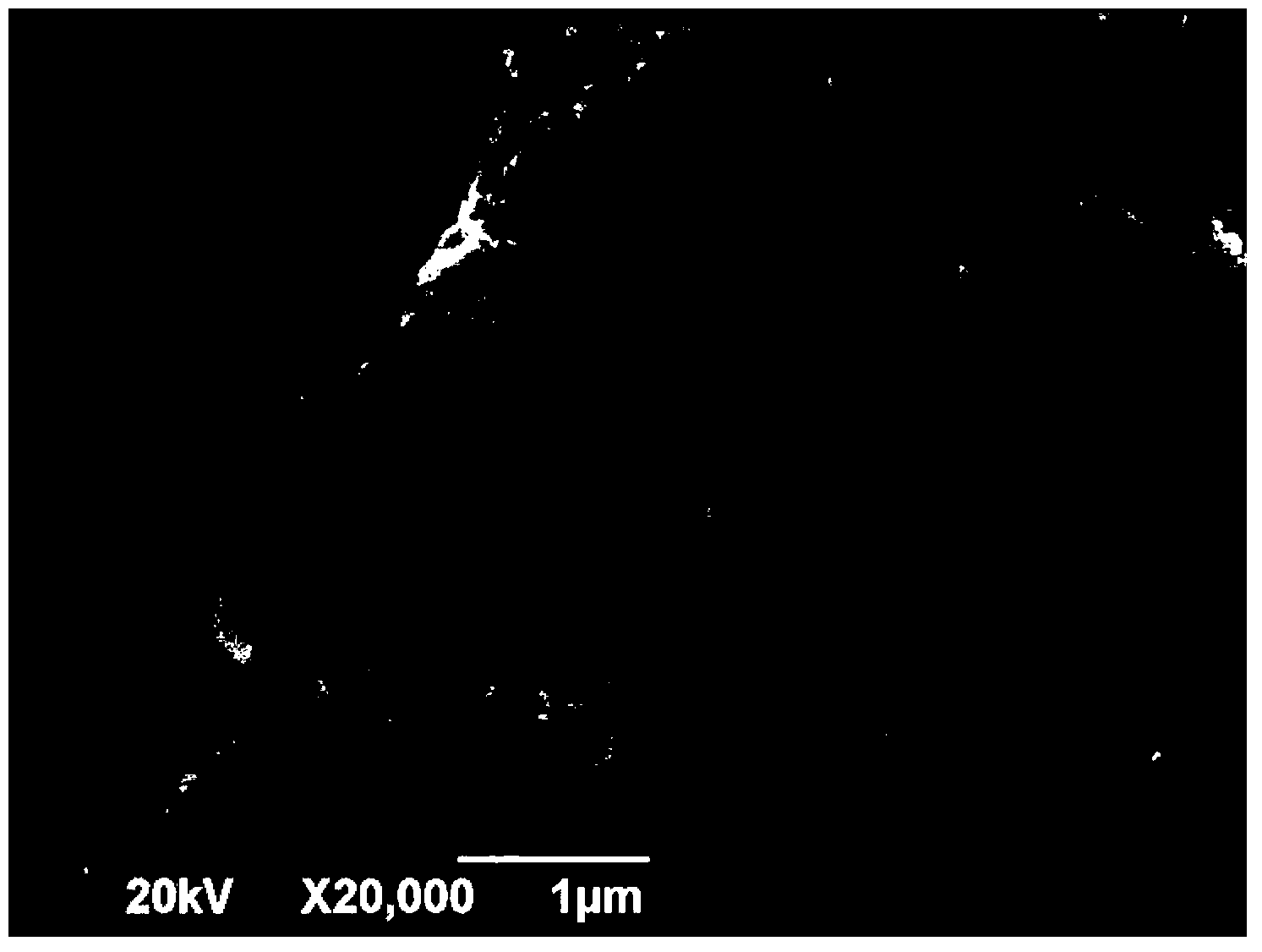

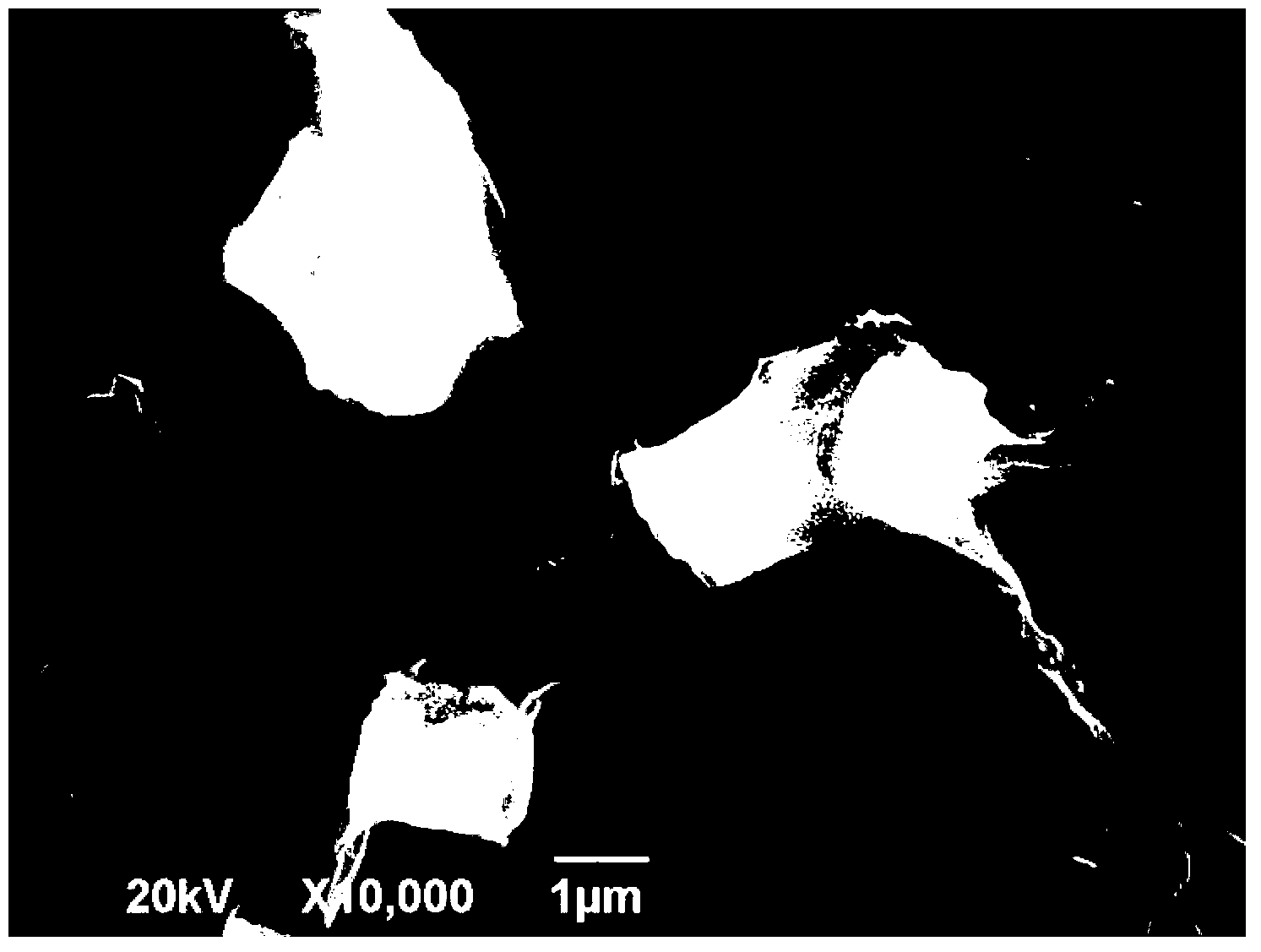

[0027] According to the ratio of applying 12ml concentrated sulfuric acid, 5g potassium persulfate and 5g phosphorus pentoxide for every 10 grams of graphite flakes, the reactants were mixed, reacted at 80°C for 4.5 hours, cooled naturally to room temperature, then diluted with distilled water, filtered, and washed until Neutral, natural drying to obtain pre-oxidized graphite; according to the ratio of applying 72ml of concentrated sulfuric acid and 30g of potassium permanganate per 10 grams of pre-oxidized graphite, slowly add pre-oxidized graphite to the concentrated sulfuric acid in an ice-water bath, and then slowly add potassium permanganate, Stir and react for 10 to 20 minutes at a temperature not exceeding 20°C, then raise the temperature to 35°C and continue stirring for 2 hours, then slowly add deionized water, raise the temperature to 95°C, continue stirring for 30 minutes, then add an appropriate amount of hydrogen peroxide to reduce the residual Oxidant, the solutio...

Embodiment 2

[0034] The preparation steps of graphite oxide and α-type manganese dioxide are the same as in Example 1.

[0035] Take 100mg of graphite oxide and dissolve it in 100ml of distilled water, ultrasonically dissolve it completely to form a graphene oxide solution, add 2.5mg of LD dispersant, according to the ratio of the mass of graphene oxide to the mass of manganese oxide is 1:1.3, add 130mg just prepared Nano manganese dioxide particles, ultrasonically form a uniformly dispersed graphene oxide / manganese dioxide solution.

[0036] Add 1.2ml of 80% hydrazine hydrate solution to the mixed solution of graphene oxide and manganese dioxide, heat, stir and reflux until complete reaction, separate solid from liquid, wash and dry to obtain graphene-coated manganese oxide composite electrode material.

[0037] The implementation steps of the electrochemical performance test are the same as in Example 1. The results show that the specific capacity is 167 F / g at a scanning speed of 10 mV / ...

Embodiment 3

[0039] The preparation steps of graphite oxide and α-type manganese dioxide are the same as in Example 1.

[0040] Dissolve 100mg of graphite oxide in 100ml of distilled water, ultrasonically dissolve it completely to form a graphene oxide solution, add 2.5mg of LD dispersant, according to the ratio of the mass of graphene oxide to the mass of manganese oxide is 1:9, add 900mg just prepared Nano manganese dioxide particles, ultrasonically form a uniformly dispersed graphene oxide / manganese dioxide solution.

[0041] Add 1.2ml of 80% hydrazine hydrate solution to the mixed solution of graphene oxide and manganese dioxide, heat, stir and reflux until complete reaction, separate solid from liquid, wash and dry to obtain graphene-coated manganese oxide composite electrode material.

[0042] The implementation steps of the electrochemical performance test are the same as in Example 1. The results show that it has a specific capacity of 187 F / g at a scanning speed of 10 mV / s, and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com