Method of manufacturing powder metallurgy nitrogen/high nitrogen containing stainless steel parts

A high-nitrogen stainless steel and powder metallurgy technology, applied in the field of powder metallurgy, can solve the problems of undisclosed preparation methods, uneven composition and structure, and decreased impact toughness, and achieve the effects of improved dimensional accuracy, uniform composition and structure, and controllable nitrogen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Raw materials: Nitrogen-containing stainless steel powder, composition (weight percent): 16.74% Cr, 12.02% Mn, 2.08% Mo, 0.5% Si, 0.8% N, the rest is iron; average particle size 9.1 μm, bulk density 4.0 g cm -3 , tap density 4.6g·cm -3 , D10 = 3.5 μm, D50 = 9.00 μm, D90 = 16 μm, N wt% = 0.85%; thermoplastic wax-based binder is used, and the powder loading rate is 55%.

[0044] Heat and knead the powder and binder evenly, and then granulate to obtain a uniform granular injection material; wherein the binder is composed of 70% paraffin, 29% high-density polyethylene, and 1% stearic acid (both by weight percentage) . Install the mold on an injection molding machine for injection molding to obtain a part blank. Soak the obtained blank in an organic solvent for a certain period of time to ensure that more than 80% of the wax is dissolved. Dry in a vacuum oven at a temperature of 100° C. for 120 minutes. After drying, thermal degreasing is carried out in a resistance furn...

Embodiment 2

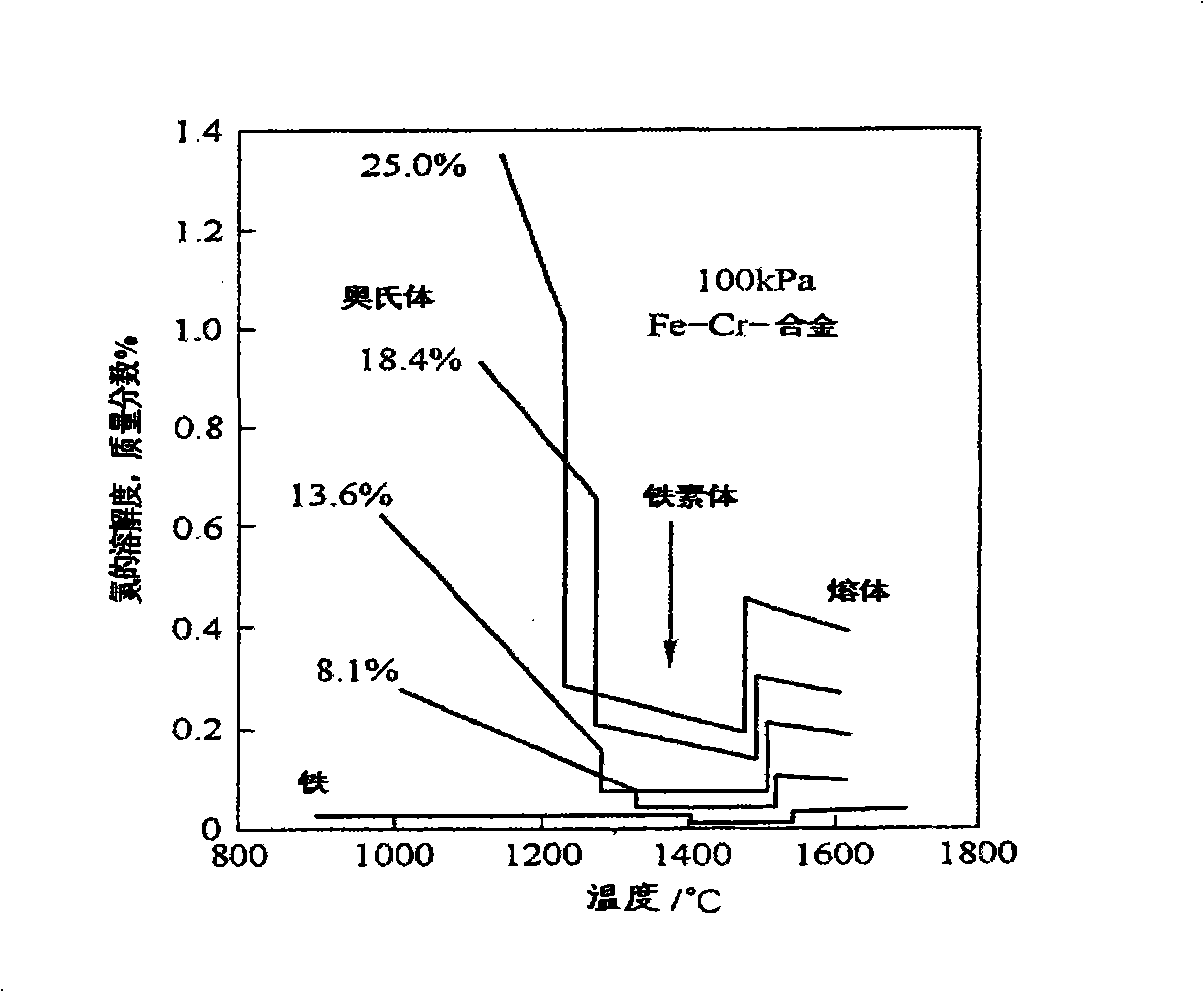

[0046] The molding and degreasing process of raw materials and parts is the same as in Example 1. After degreasing, in sintering isostatic pressing, a mixed gas of 0.15 MPa nitrogen and hydrogen is used, wherein the partial pressure of nitrogen is 0.1 MPa, and the temperature is raised at a heating rate of 7 °C / min. Carry out sintering at 1400°C and keep it warm for 120min. When the sintering density reaches more than 95%, and the connected pores basically disappear, increase the gas pressure to 9MPa, of which the nitrogen partial pressure is 0.1MPa, and the rest is argon partial pressure. Keep it for 180min, and the sintering density of the parts is close to 100%, reduced pressure, quick cooling. The whole process keeps the partial pressure of nitrogen consistent with the solubility of nitrogen in the alloy system, so that the nitrogen content in the alloy does not fluctuate significantly, and δ-ferrite is not formed. Finally, the relative density>99% can be obtained, R p0.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com