A kind of preparation method of nitrogen-doped lignin-based carbon fiber composite material

A technology of lignin-based and composite materials, which is applied in the field of preparation of lignin-based carbon fiber composite materials, can solve the problems of not being able to apply supercapacitors well, and achieve the effects of improving electrochemical performance, simple equipment, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

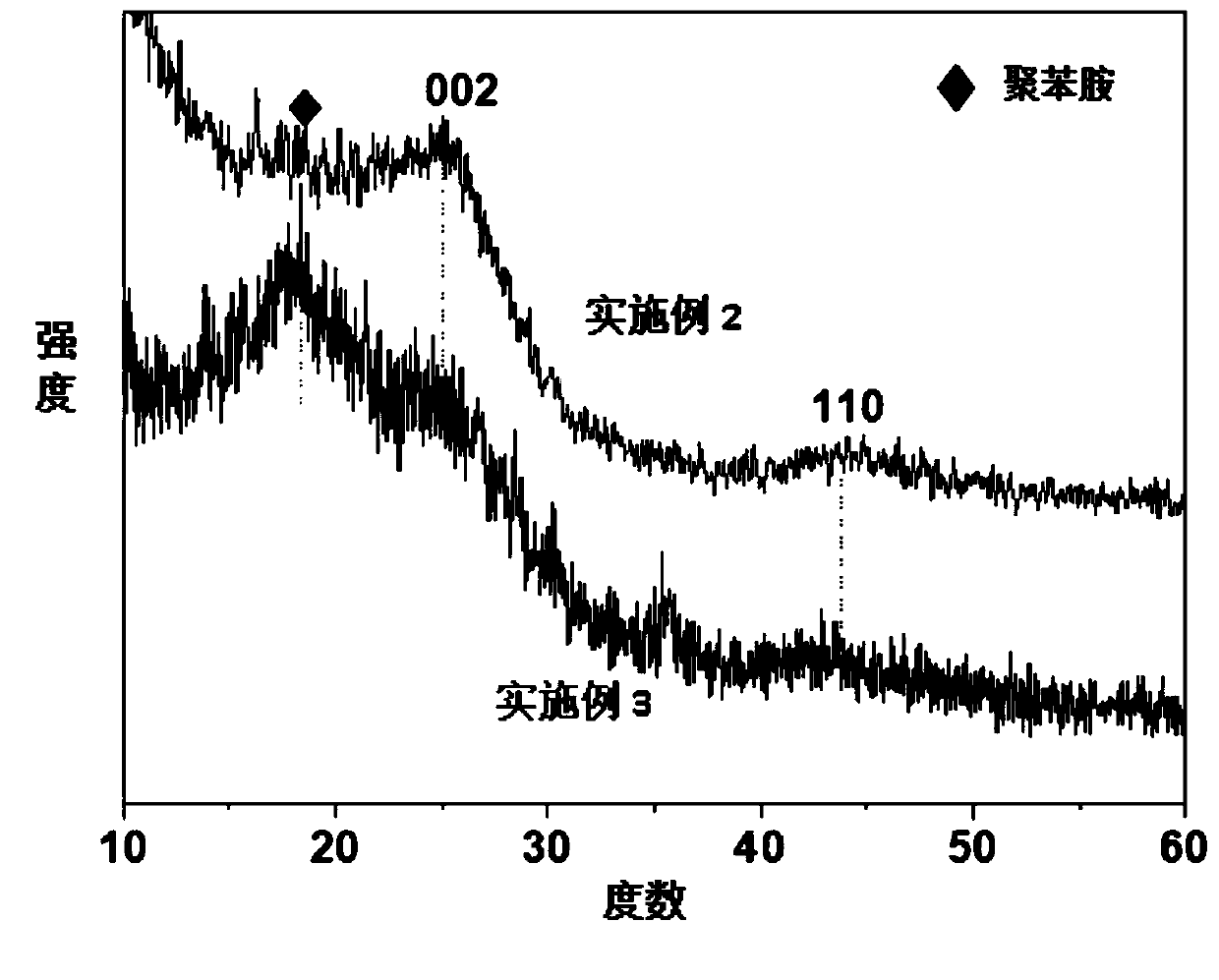

[0037]At room temperature, dissolve 0.65g of PAN and 0.1g of LN in 5ml of DMF, stir fully on a magnetic stirrer until completely dissolved, add 0.08g of urea to the prepared polymer solution, continue stirring until completely dissolved, and obtain a spinning liquid. Use a 10ml syringe to extract the spinning solution, set the spinning voltage to 15kv, the receiving distance to 15cm, and the advancing rate to 0.5ml / h, and use tinfoil to collect the nanofiber precursor produced by high-voltage electrospinning, and dry it in the air for 12h. The dried nanofiber precursor is immersed in a solution of 0.1% aniline / hydrochloric acid (hydrochloric acid concentration is 1mol / L, 40ml) for 12h with a weight percentage concentration, and then 40ml hydrochloric acid (1mol / L ) solution, and keep the temperature at 0-4°C for 4h. The obtained nanofibers were washed several times with deionized water, dried in a drying oven at 60 °C for 12 h, and then pre-oxidized in a tube furnace at 260 °...

Embodiment 3

[0043] Except that the pre-oxidized fibers were calcined under an inert nitrogen atmosphere in a tube furnace, the heating rate was 5°C / h, the calcining temperature was 900°C, and the calcining time was 2h, to obtain LCNFs / PANI / N-9 carbon fibers, the rest Same as Example 2.

[0044] Electrochemical performance test: In 1mol / l sulfuric acid electrolyte, the current density is 1A / g, and the specific capacitance of LCNFs / PANI / N-9 carbon fiber is 199.5F / g.

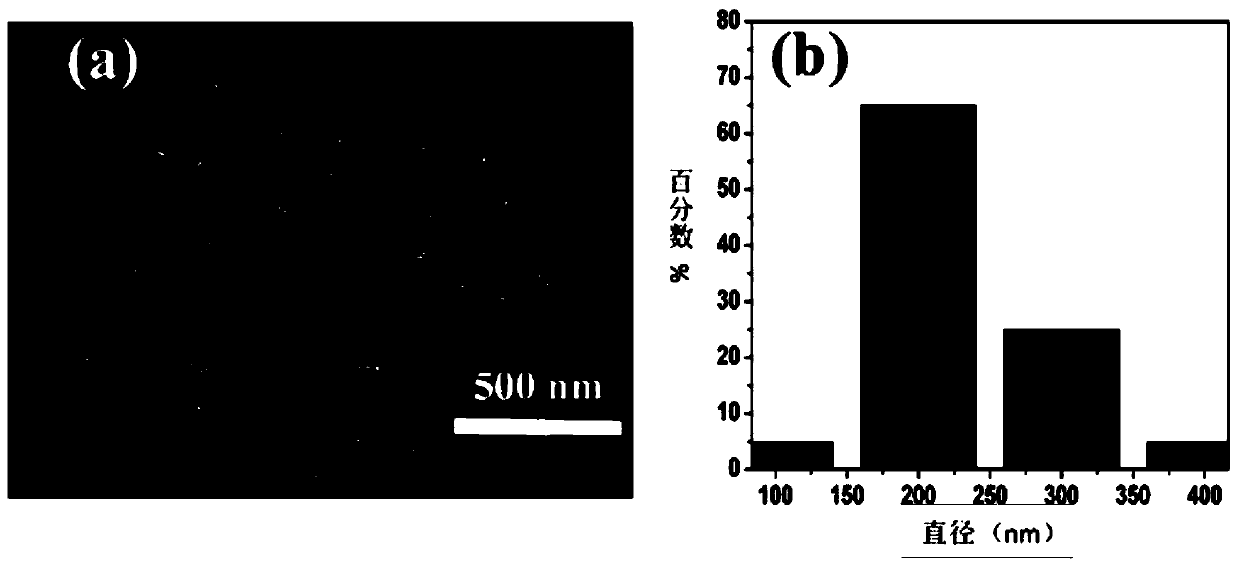

[0045] figure 1 It is a scanning electron micrograph of the carbon fiber prepared according to this embodiment. It can be seen from the figure that the size of the carbon nanofiber is relatively uniform, and PANI is compounded on the surface. figure 2 a is the transmission electron micrograph of the carbon fiber prepared according to the present embodiment, figure 2 b is a distribution diagram of the diameters of carbon fibers prepared according to this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com