Electric motor with reduction gear mechanism

A reduction gear and motor technology, applied in the field of motors, can solve problems such as damage, and achieve the effect of reducing assembly steps, reducing noise, and reducing the number of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

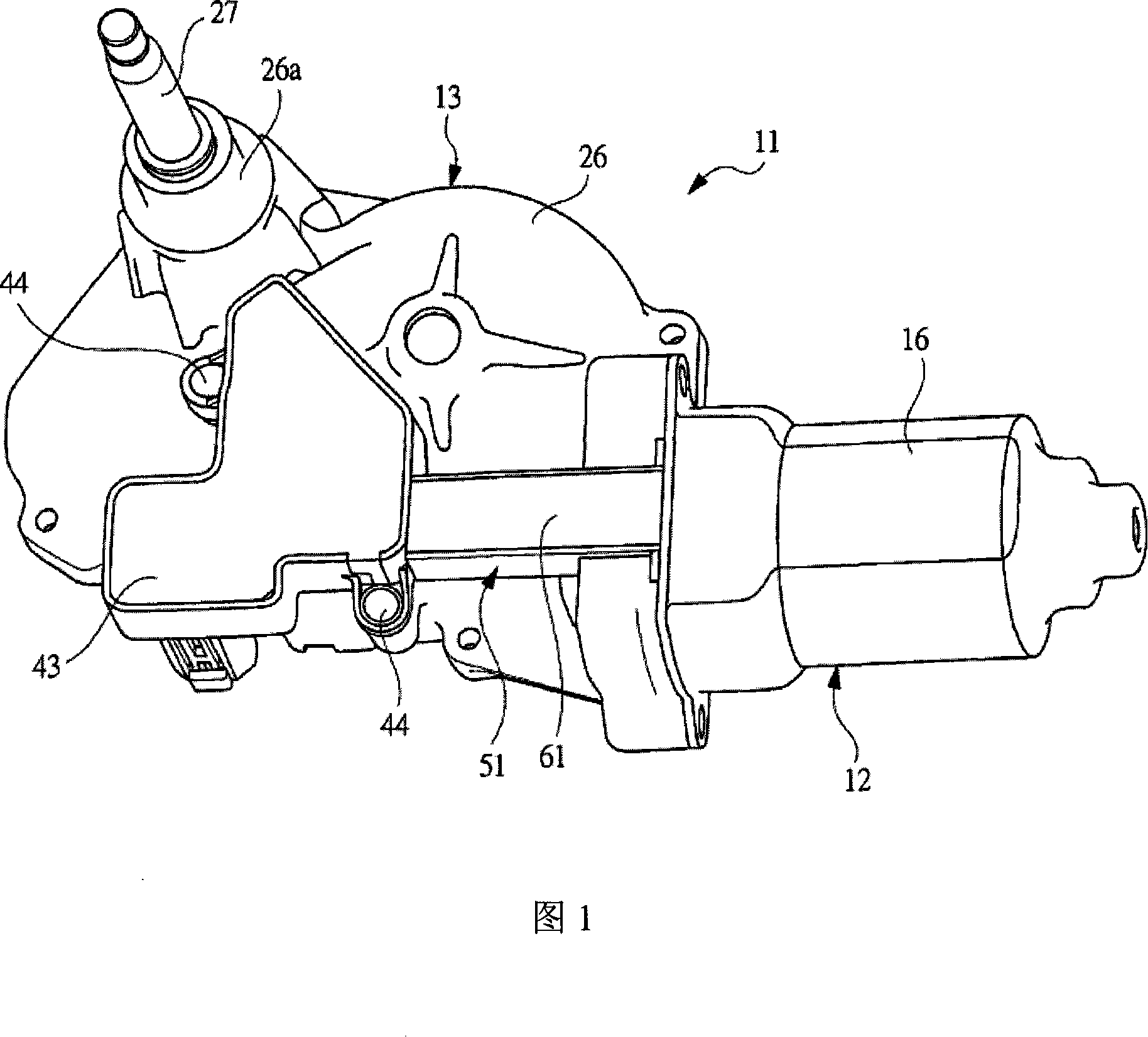

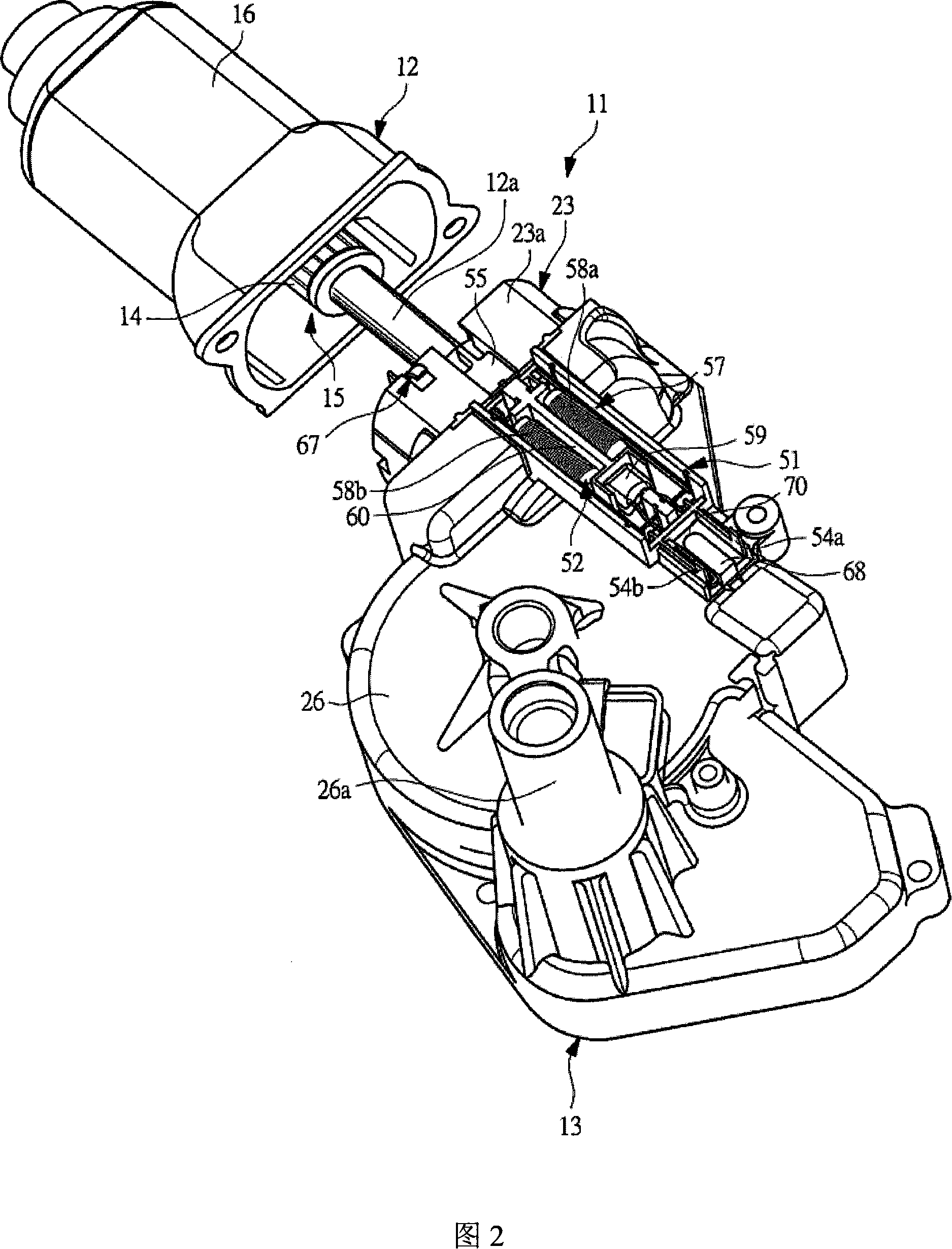

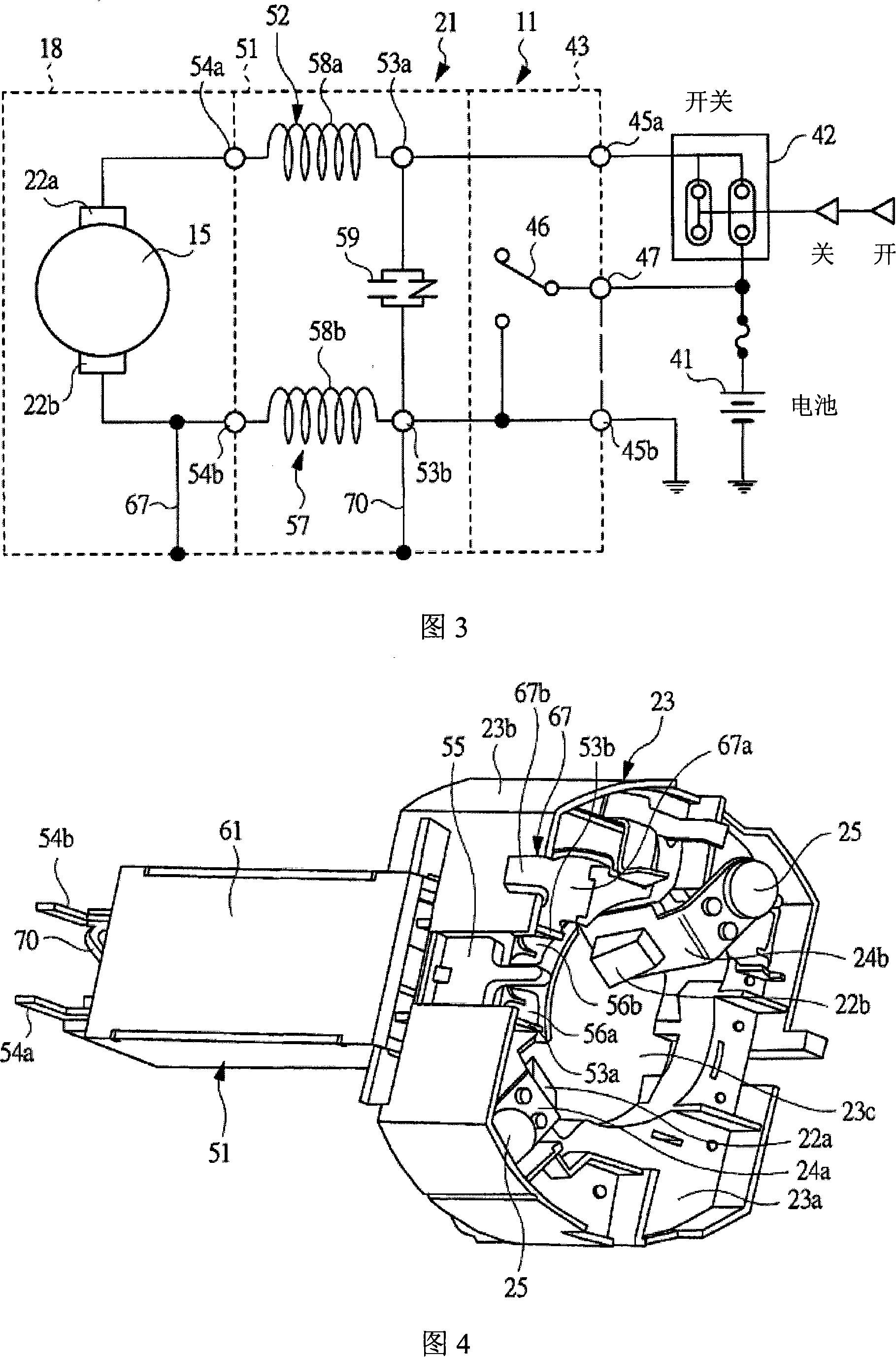

[0049] FIG. 1 is a perspective view of a wiper motor according to an embodiment of the present invention, and FIG. 2 is an exploded perspective view of the wiper motor shown in FIG. 1 .

[0050] The wiper motor 11 shown in FIG. 1 is used as a driving source of a rear wiper disposed on a vehicle as a motor having a reduction gear mechanism in which a motor main body 12 and a reduction gear device 13 are combined into a One.

[0051] As shown in Figure 2, the motor main body 12 is used as a brushed motor, and the brushed motor is configured with a rotating shaft 12a, wherein a commutator 14 and an armature iron core (not shown) are fixed on the rotating shaft 12a superior. A plurality of coils (armature coils) not shown in the figure are wound on the slots of the armature core, and the ends of the coils are respectively connected to the corresponding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com