Ceramic double-side three-dimensional integrated structure and packaging method of ultra-wideband radio frequency micro-system

A three-dimensional integration and micro-system technology, applied in the direction of electrical components, electrical solid devices, circuits, etc., can solve the problems of difficulty in adapting to the development needs of micro-system integration of electronic equipment, limited integration density, and interconnection interface occupancy, etc., to achieve internal integration density The effect of lifting, fewer assembly steps, and lower volume occupancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

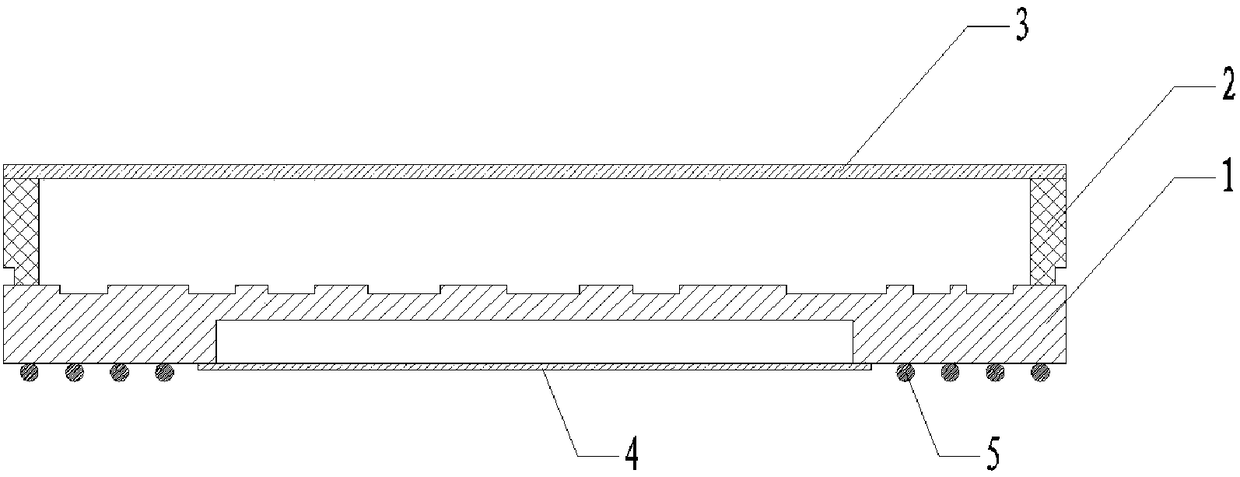

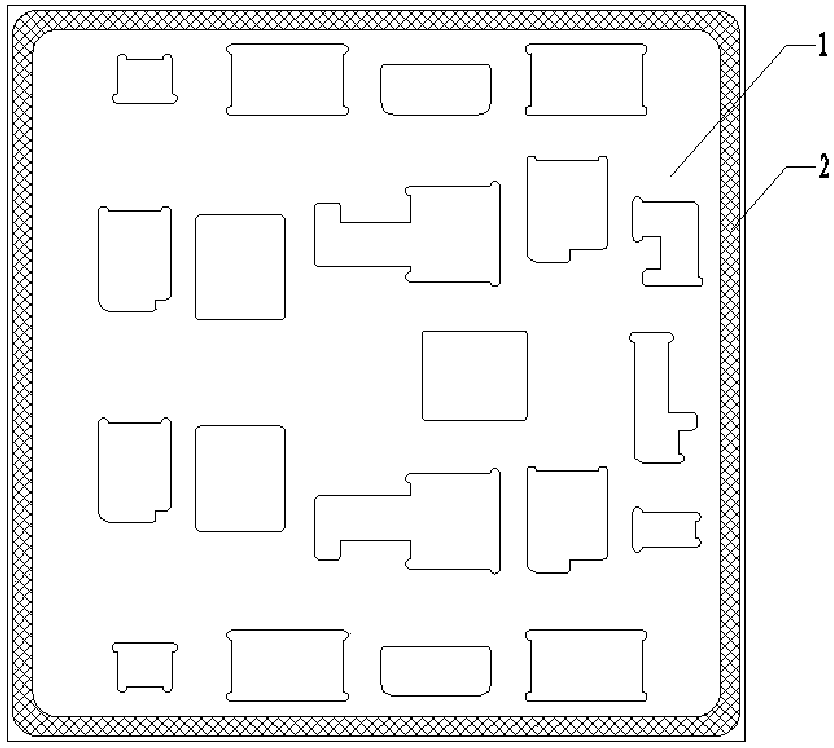

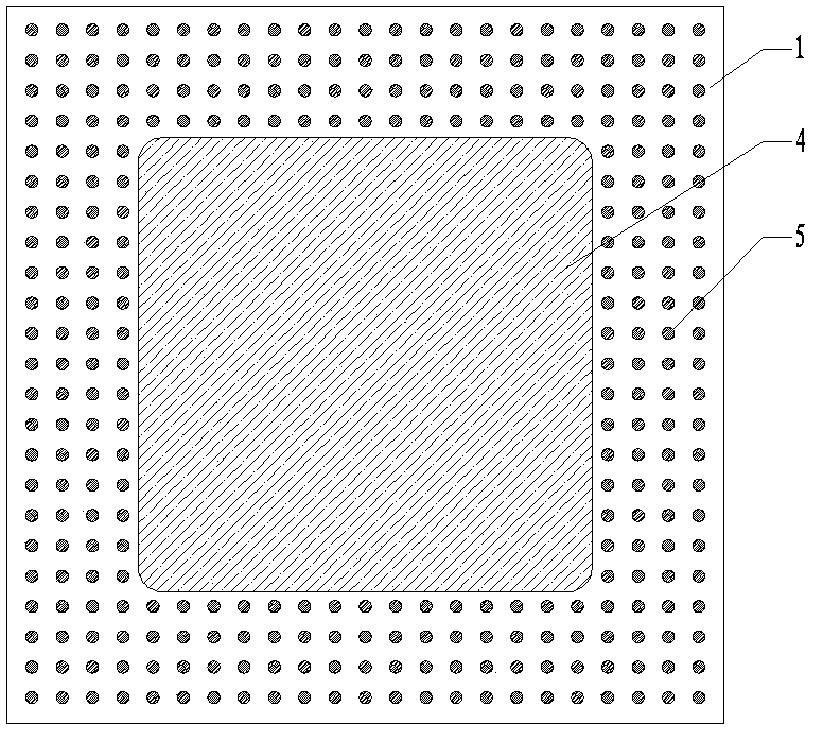

[0045] The multilayer ceramic double-sided three-dimensional integrated architecture of this example ultra-wideband RF microsystem is as follows: figure 1 , figure 2 and image 3 shown. Including multilayer ceramic substrate 1, metal micro frame 2, front cover 3, back cover 4 and BGA solder balls 5:

[0046] Both sides of the multilayer ceramic substrate 1 are provided with cavities for installing chips, the metal micro frame 2 is welded on the front of the multilayer ceramic substrate 1, and the front cover plate 3 is welded on the metal micro frame 2, The back cover plate 4 is welded on the back cavity groove of the multilayer ceramic substrate 1, BGA pads are arranged on the back side of the multilayer ceramic substrate 1 except the back cover plate 4, and the BGA solder balls 5 pass through the BGA pads Soldered on the back of the multilayer ceramic substrate 1.

[0047] The packaging method of the multilayer ceramic double-sided three-dimensional integrated architect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com