A kind of low eddy current loss soft magnetic block material and its manufacturing method

A block material, eddy current loss technology, applied in the direction of magnetic materials, magnetic objects, electrical components, etc., can solve the problems of high cost of magnetic conductive powder, large eddy current loss, uneven magnetic conduction of magnetic conductors, etc., to improve processing and installation efficiency , reduced eddy current loss, and stable magnetic permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

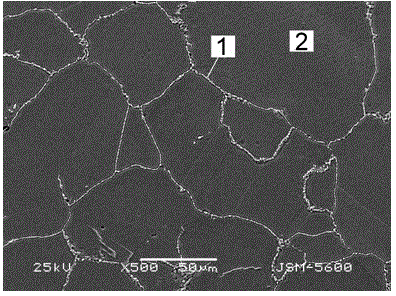

[0045] A silicon steel (Si(wt,%) ≥ 2.8) soft magnetic block material with low eddy current loss is provided. The silicon steel soft magnetic block material is composed of ferrosilicon alloy grains and a silicon oxide dielectric film bonded to the surface of the grains.

[0046] Put a silicon steel (Si(wt,%)≥2.8) slab (length 400mm, width 100mm) with a thickness of 60mm into a silicon-molybdenum electric furnace for heating, and feed a mixed gas with a constant flow rate of 4000ml / min and a pressure of 0.11Mpa , the mixed gas contains 55% oxygen and 45% nitrogen by weight, so that the furnace is heated to 1300°C and kept for 0.5h, and then enters the dynamic diffusion oxidation process.

[0047] Change the gas feeding method to the pulsating flow feeding method, the pulsating frequency is 50Hz, the mixed gas ratio (wt,%) is adjusted to 20 oxygen, 79 nitrogen and 1 water vapor, and the flow rate is 8000ml / min, keep the pressure of the mixed gas at 0.11Mpa and heat the furnace to ...

Embodiment 2

[0051] Provide a low eddy current loss electroslag remelted 0Cr16 corrosion-resistant soft magnetic alloy (chemical composition (wt,%): C≤0.03; Si0.23; Mn0.65; S≤0.02; P≤0.02; Cr16.5; Residual Fe) Cylindrical billet, the size is Φ120×450mm. The material is mainly composed of chromium-iron alloy grains and the main compound combined on the surface of the grains is a chromium oxide dielectric film.

[0052] Put the alloy into the furnace and heat it at 1300°C, feed a mixed gas with a constant gas flow rate of 5000ml / min and a pressure of 0.11Mpa, and its ratio (wt,%) is 60% oxygen and 40% nitrogen. The gas feeding method is changed to the pulsating flow feeding method, the pulsating frequency is 60Hz, the gas mixture ratio (wt,%) is adjusted to 40% oxygen, 59% nitrogen and 1% water vapor, the flow rate is 10000ml / min, and the pressure is maintained 0.11Mpa and heat the furnace to 1330°C for 3 hours, after repeated heating and forging with a deformation of ≤10% each time, it is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com