LCD with function of preventing light leak, and backlight module

A liquid crystal display, backlight module technology, applied in static indicators, optics, instruments, etc., can solve the problems of inconvenient positioning of the shading tape 12, increase manufacturing costs, slow down production speed, etc., to prevent light leakage, reduce assembly steps, The effect of increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

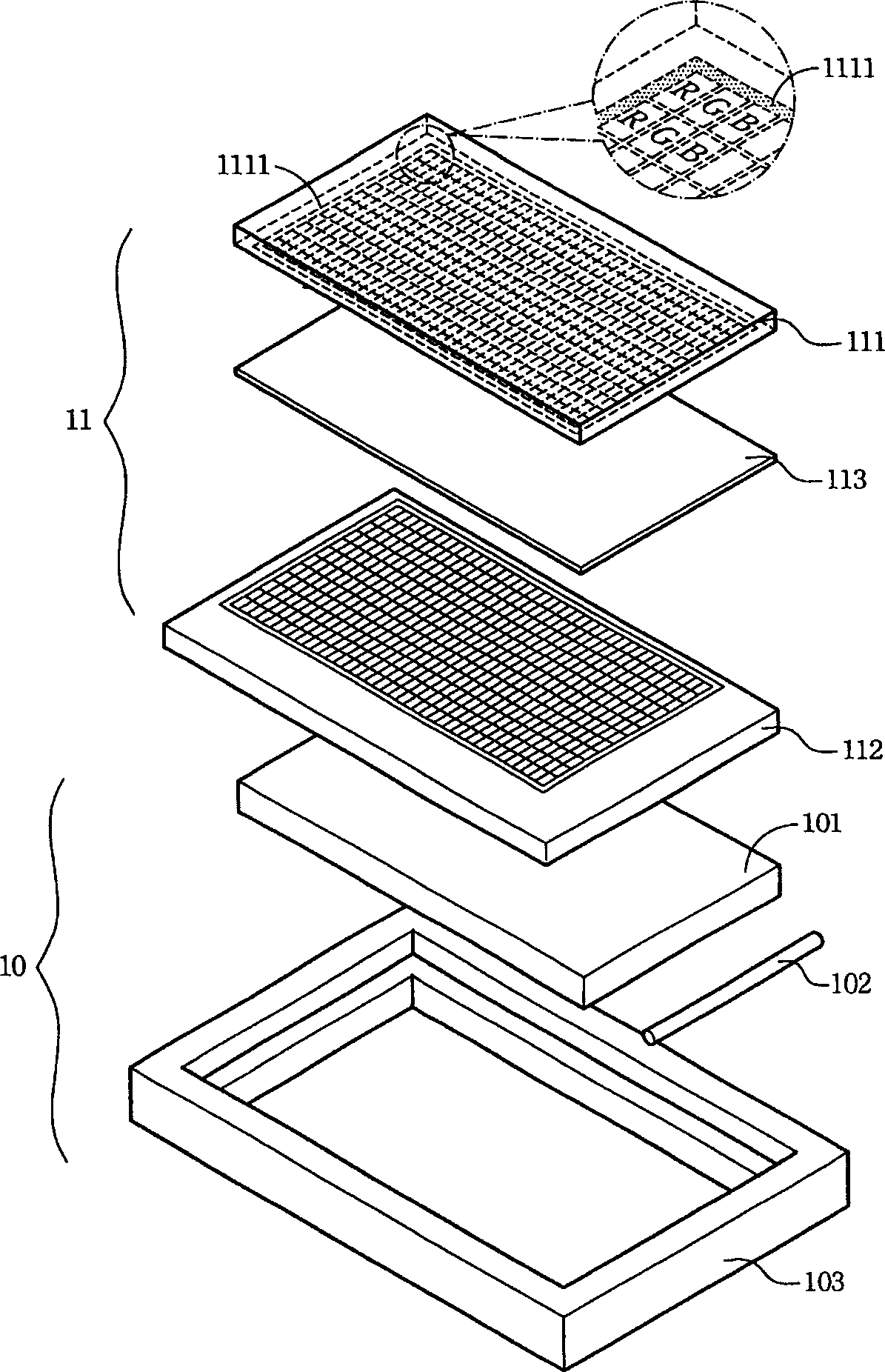

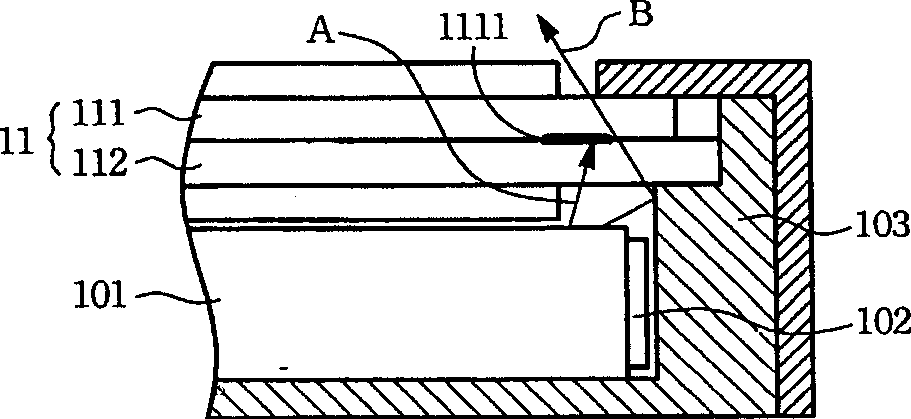

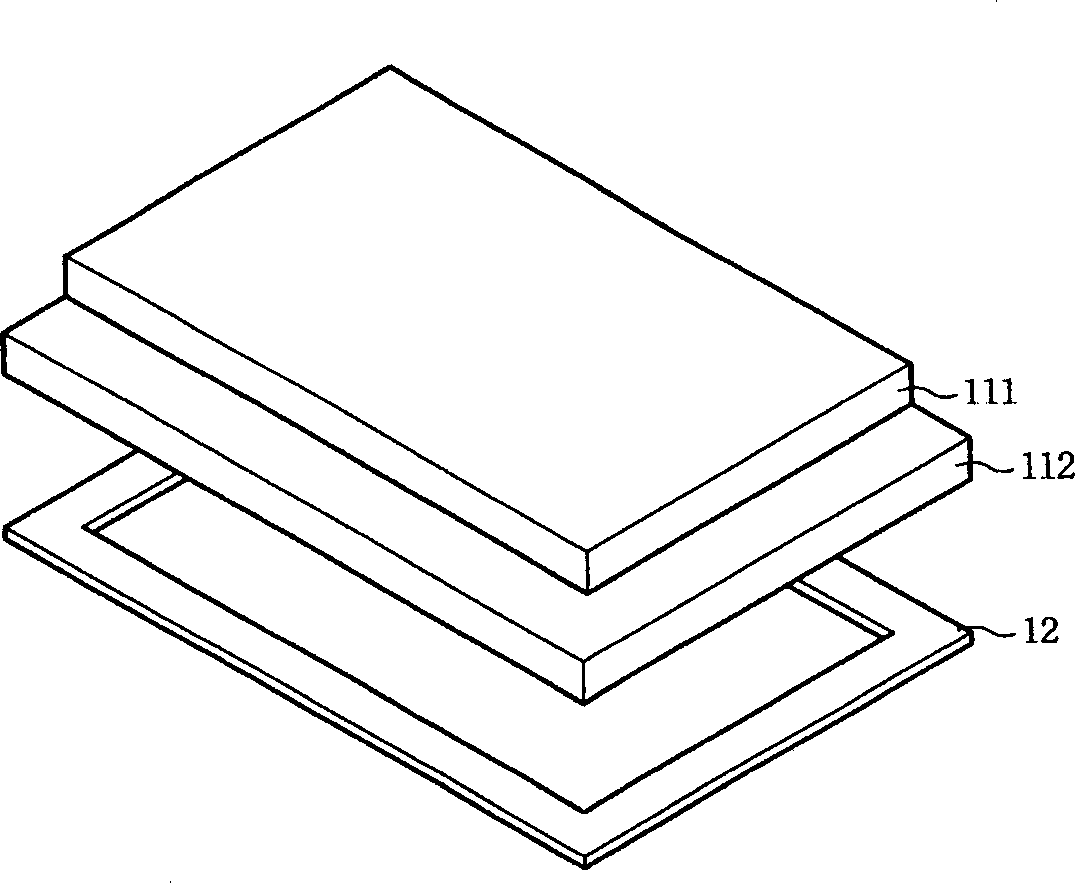

[0036] Figure 4 Shown is a schematic cross-sectional view of an embodiment of the liquid crystal display of the present invention. The liquid crystal display 2 includes: a liquid crystal panel 21 and a backlight module 22 .

[0037] The liquid crystal panel 21 has an upper substrate 211 and a lower substrate 212 . According to whether to display images, the upper and lower surfaces of the liquid crystal panel are divided into a display surface A1 and a non-display surface A2. The user watches the image through the display surface A1 and obtains the required information. Moreover, an opaque frame 2111 is provided on the surface of the upper substrate 211 of the liquid crystal panel 21 .

[0038] The backlight module 22 further includes: a light guide plate 221 , a light source 222 and a frame 223 .

[0039] The light guide plate 221 is disposed on the non-display surface side of the liquid crystal panel 21 , that is, on the same side as the non-display surface A2 of the li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com