Contact finger spring assembly tooling

A technology for assembly tooling and touch fingers, applied in the field of assembly tooling, can solve the problems of increasing use and storage costs, scratching the silver plating layer, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

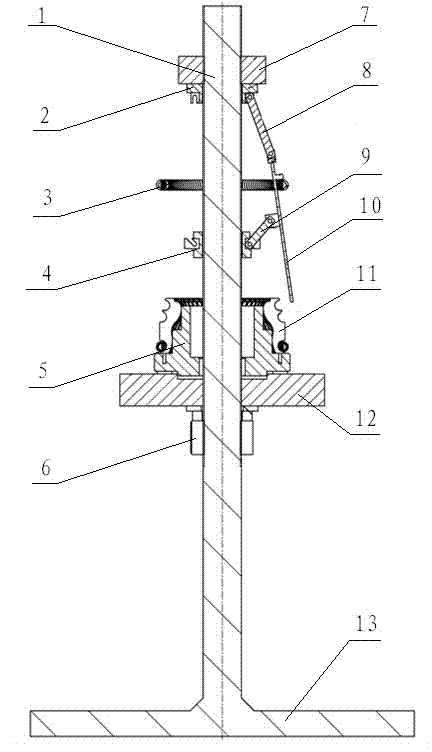

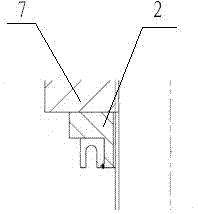

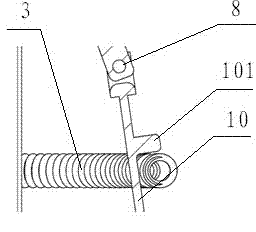

[0016] The embodiment of contact finger spring assembly tooling of the present invention: as figure 1 , figure 2 , image 3 As shown, it includes a fixed platform, a support base 12 and an umbrella rib mechanism. The fixed platform is composed of a base 13 and a screw 1 fixed on the base 13 extending in the up and down direction. The support base 12 is slidably sleeved on the screw 1 It is used to support the contact seat 5 equipped with petal-shaped contact fingers 11. On the screw rod 1, a stop structure 6 is threaded to cooperate with the lower end surface of the support seat 12. The stop structure 6 adopts the internal thread and the screw rod. The nut fitted with the external thread thread can limit the position of the support seat 12 by relying on the stop structure 6, and can adjust the height of the support seat 12 at the same time, and the umbrella rib mechanism is arranged above the support seat. The umbrella bone mechanism includes a guide sleeve 2 which is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com