Breaker semi-automatic auxiliary assembling device

A technology of auxiliary assembly device and automatic detection device, which is applied in the direction of emergency protection device, emergency protection device manufacturing, circuit, etc., can solve the problems of poor assembly consistency and continuity, many circuit breaker parts, and affect the assembly quality, etc., to ensure Consistency, ensuring product quality, saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

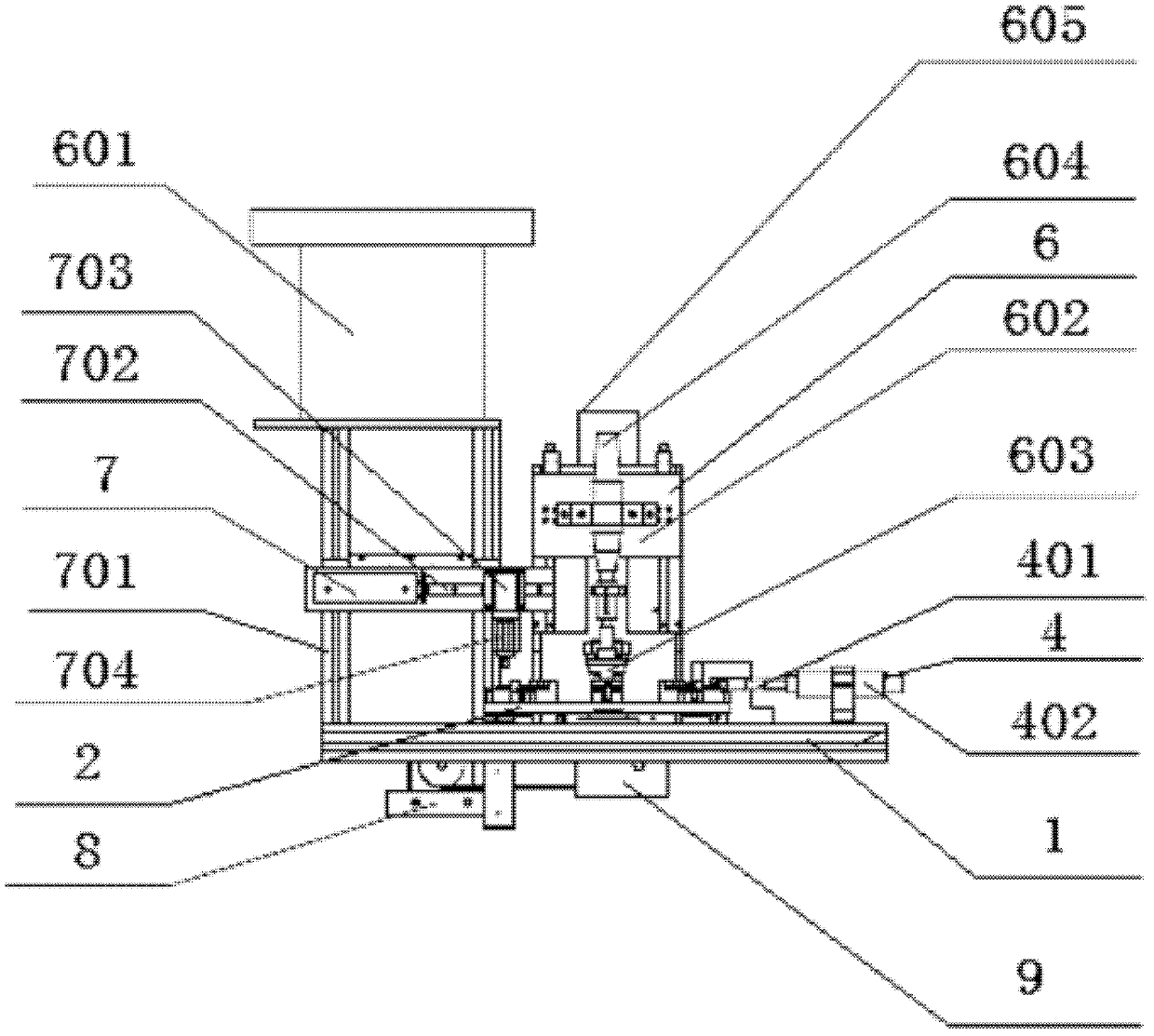

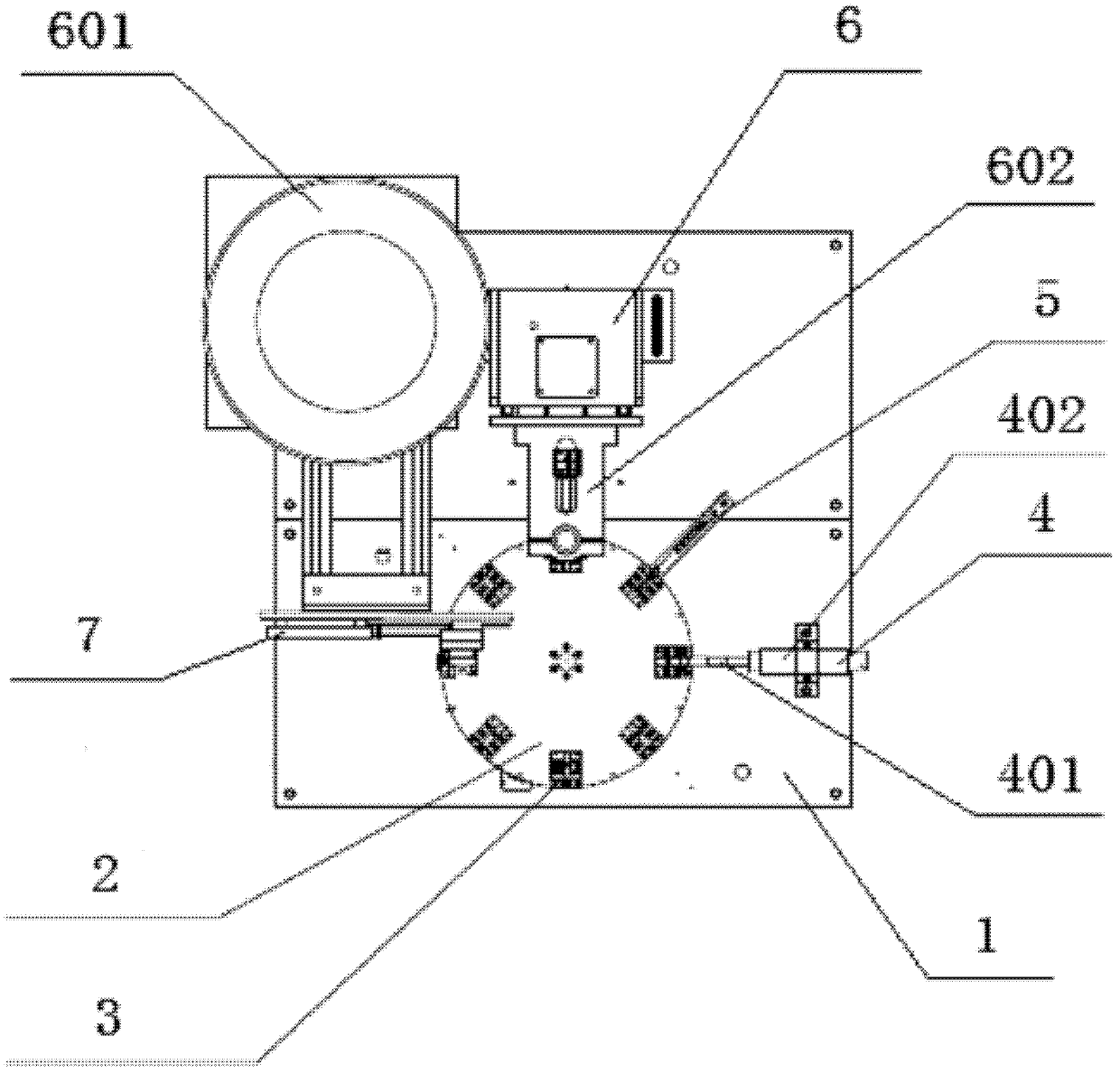

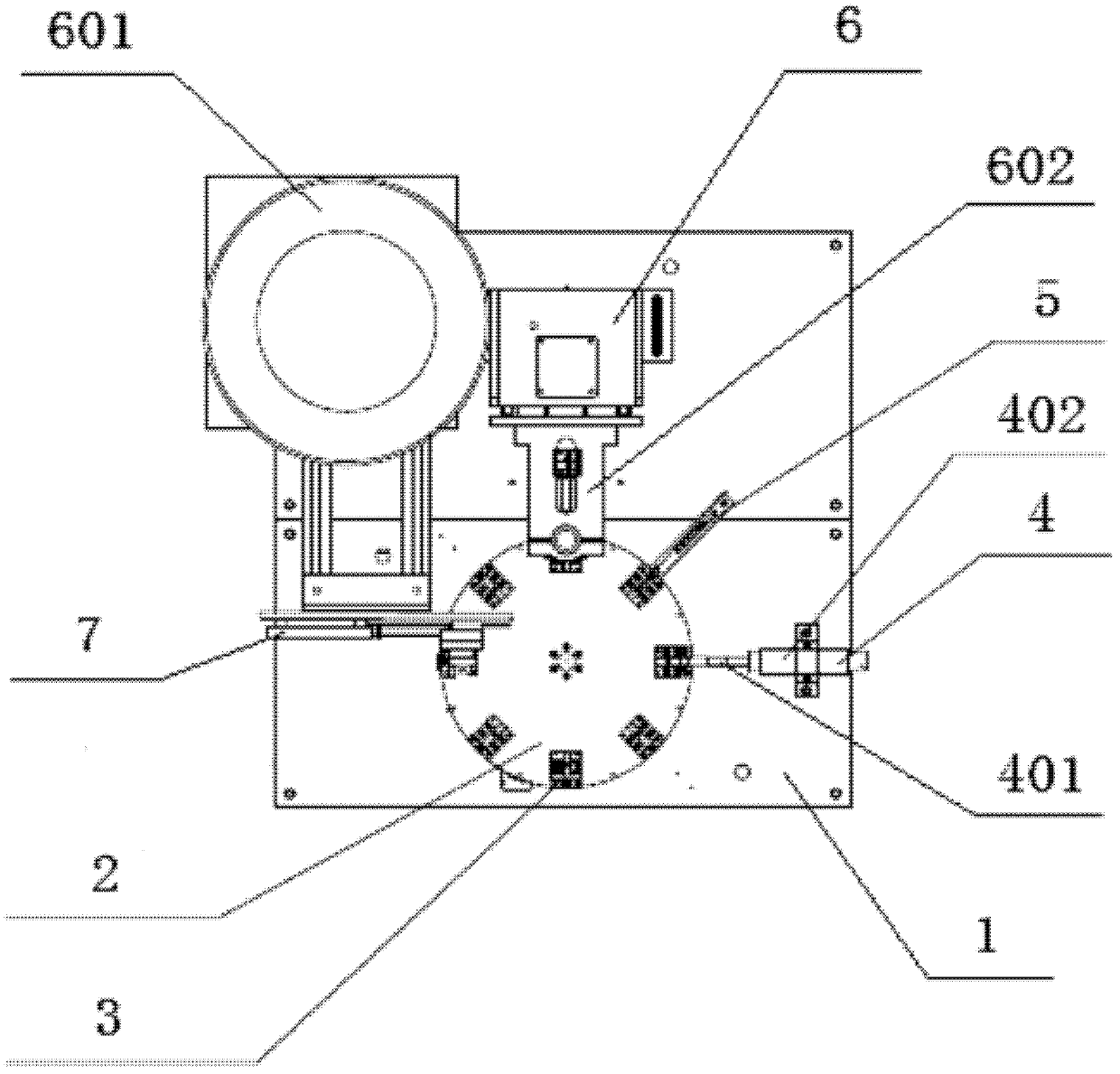

[0024] Example: Combine figure 1 , figure 2 As shown, in the semi-automatic auxiliary assembly device for circuit breakers provided in this embodiment, the turntable 2 and its driving device are installed on the working platform 1, and the driving device is a combination of a three-phase motor 8 and a cam splitter 9. The cam divider 9 is installed on the bottom of the turntable 2 and is connected with the output shaft of the three-phase motor 8 . In this embodiment, eight circuit breaker assembly pre-assembly jigs 3 are arranged at uniform intervals on the circumference of the turntable 2; at the same time, casing riveting devices 4, Product automatic detection device 5, screw automatic assembly device 6 and manipulator retrieving device 7.

[0025] The casing riveting device 4 in this embodiment is composed of a riveting punch 401 and a riveting cylinder 402 connected with the riveting punch 401 . The product automatic detection device 5 is a photoelectric sensor sw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com