Circuit breaker assembling device

A technology for assembling and assembling mechanism of circuit breakers, which is applied in the directions of emergency protection devices, emergency protection device manufacturing, circuits, etc., can solve the problems of low operation efficiency, pick and place for maintenance, increase the work intensity of staff, and reduce labor intensity. , The effect of improving assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

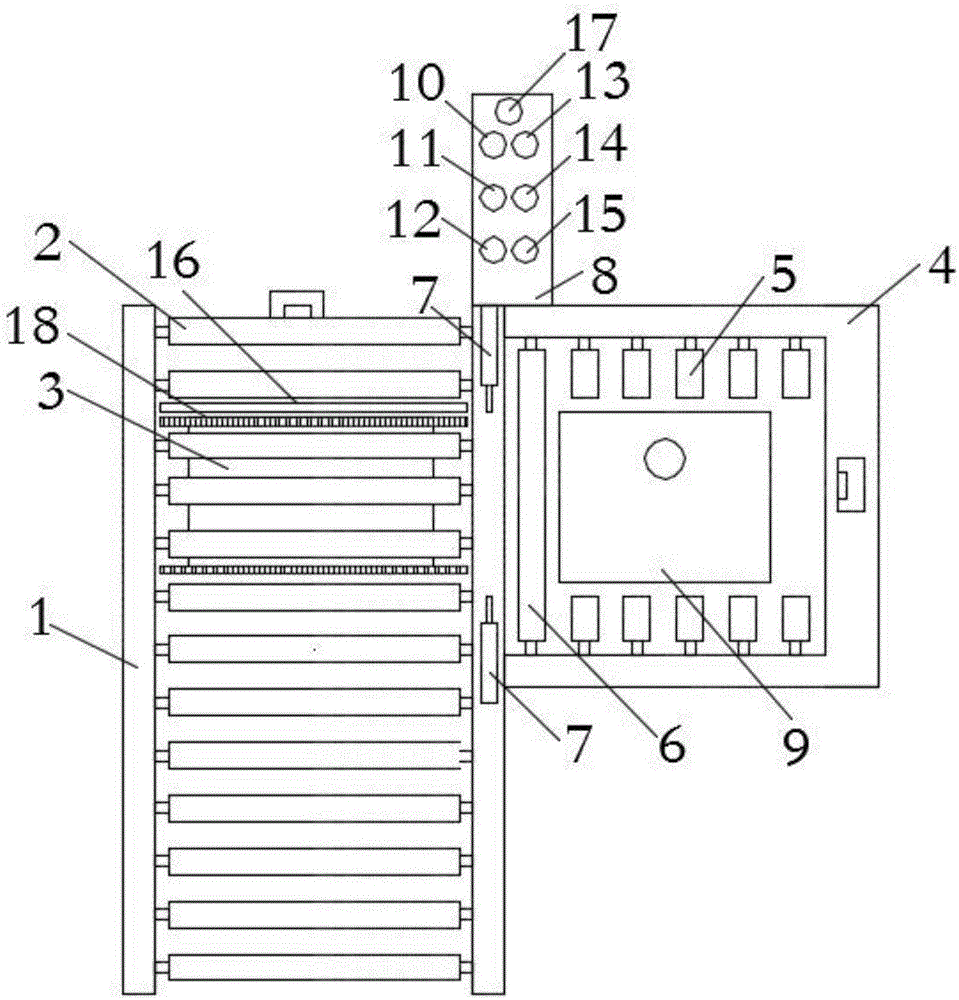

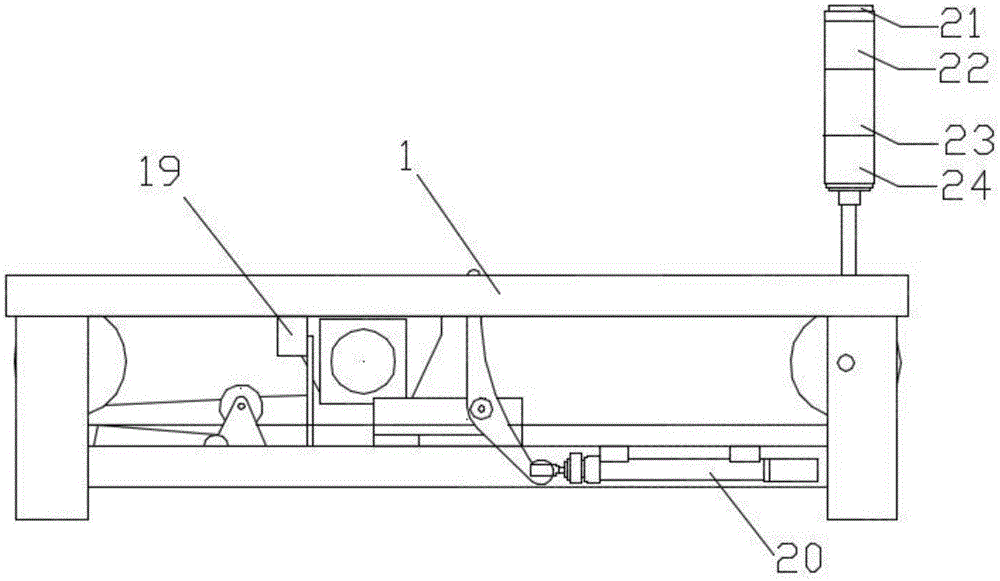

[0030] like figure 1 As shown, a circuit breaker assembly device includes a conveying mechanism and an assembly mechanism. The conveying mechanism includes a frame 1, a conveying roller 2 arranged between the 2 between several baffles 11, the jacking translation device 3 includes several chains 18 arranged between the conveying rollers 2, the chains 18 are arranged perpendicular to the rolling direction of the conveying rollers 2, the baffles 16 are parallel to the chains 18, and the baffles 16 are set On the side of the chain 18, it is used to block the transportation of the circuit breaker; the assembly mechanism is arranged on the side of the conveying mechanism, and the assembly mechanism includes the assembly frame 4, the electric drum 5, the console 8 and the console 8, wherein the assembly frame 4 is a rectangular frame structure , the assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com