Laser scanning location device

A positioning device and laser scanning technology, applied in the direction of emergency protection devices, emergency protection device manufacturing, electrical components, etc., can solve the problems of automatic assembly, debugging, and detection, etc., and achieve convenient maintenance or replacement of guide sleeves and rapid action , The effect of high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

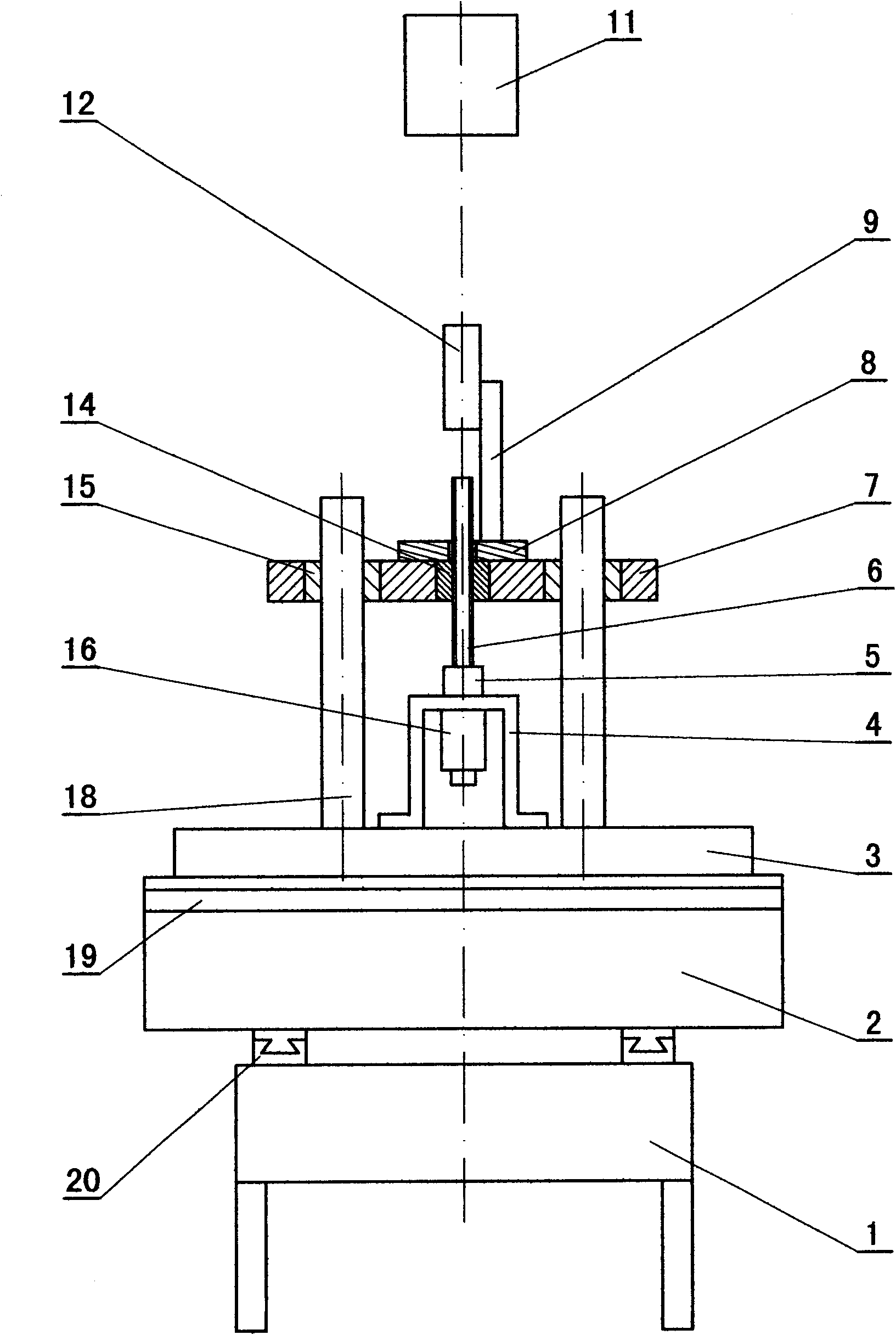

[0132] combine figure 1 ,Be explained. right first figure 1 The labels in are explained: 1 is the lower layer of the workbench; 2 is the middle layer of the workbench; 3 is the mounting plate; 4 is the connecting bracket; 5 is the connecting piece; 6 is the screw; 7 is the top plate; 8 is the support; 9 is the laser sensor 11 is a workpiece; 12 is a laser sensor; 14 is a nut; 15 is a guide sleeve; 16 is a Z-direction motor; 18 is a guide post; 19 is a second guide rail; 20 is a first guide rail.

[0133] In this example, from figure 1 It can be seen that some parts and mechanisms of the X-Y biaxial workbench include: the lower layer of the workbench 1, the middle layer of the workbench 2; the mounting plate 3, the first guide rail 20, and the second guide rail 19.

[0134] There is a first guide rail 20 between the lower layer 1 of the workbench and the middle layer 2 of the workbench; there is a second guide rail 19 between the middle layer 2 of the workbench and the mount...

Embodiment 2

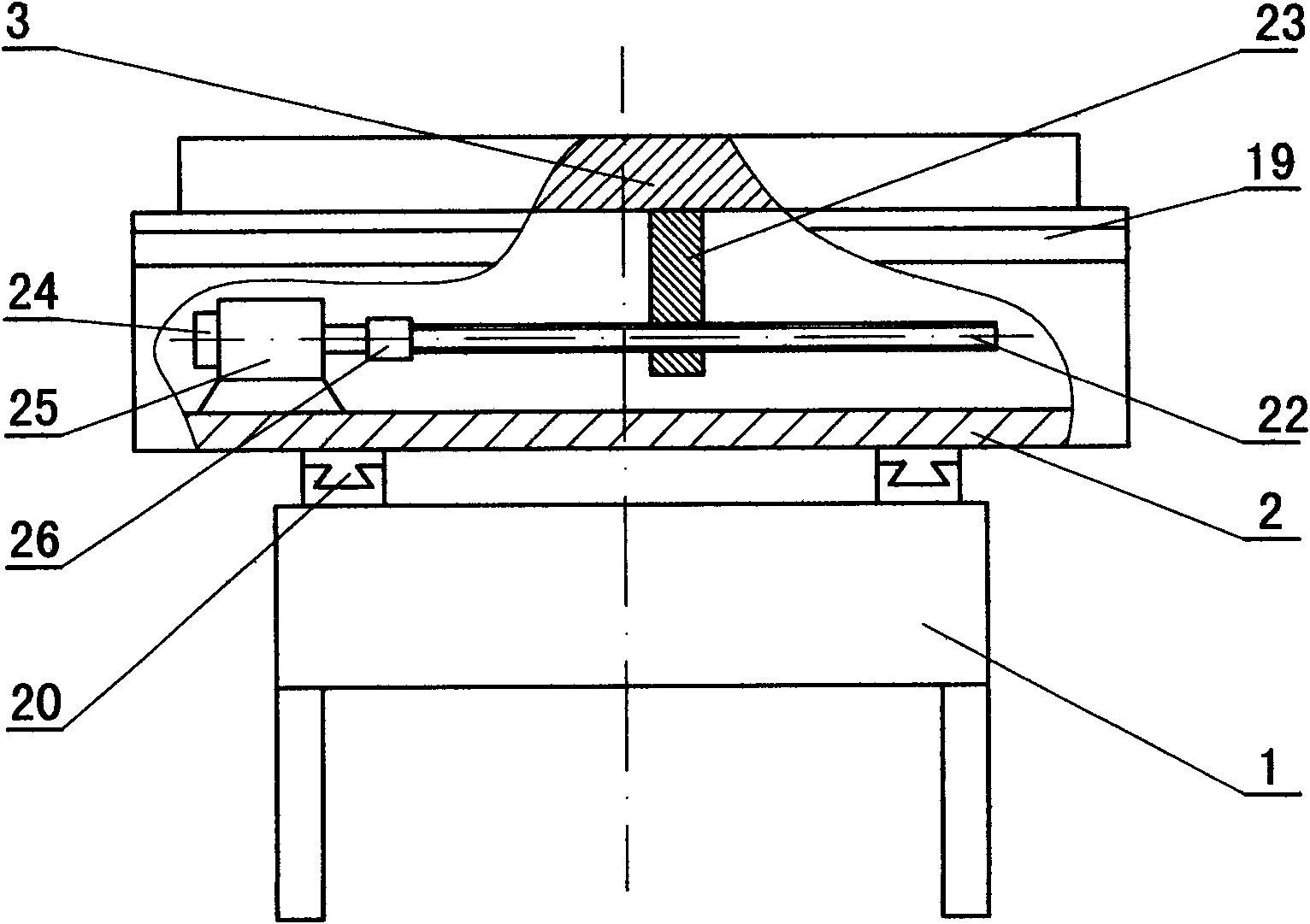

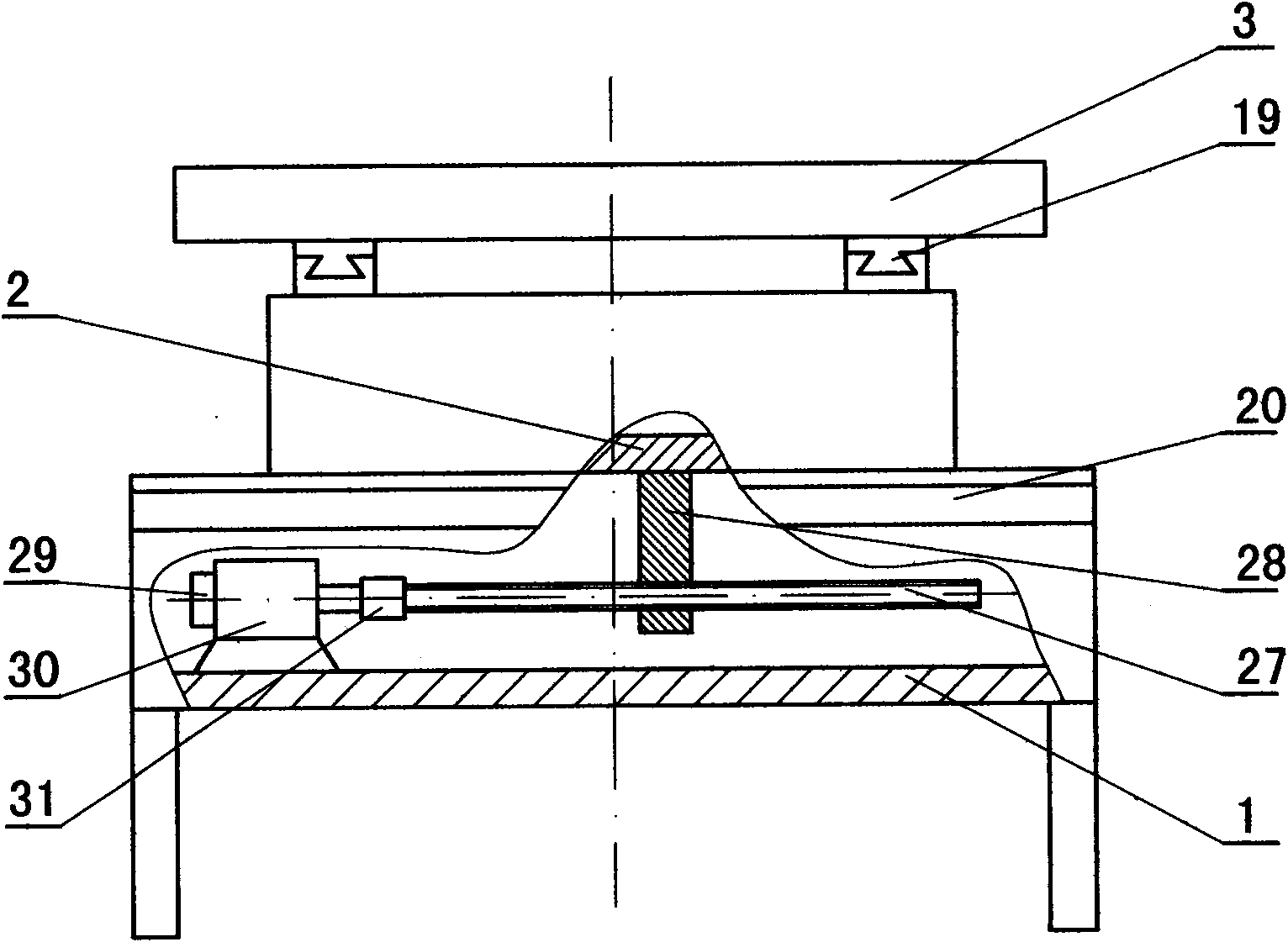

[0151] This embodiment is to give an example to illustrate a specific X-Y biaxial workbench situation. combine figure 2 , image 3 Be explained. figure 2 is the front view of this embodiment, image 3 yes figure 2 left view of .

[0152] Firstly, explain the labels in the figure: 1 is the lower layer of the workbench; 2 is the middle layer of the workbench; 3 is the mounting plate; 20 is the first guide rail; 22 is the second rotating shaft; Encoder; 25 is the second servo motor; 26 is the second connecting part; 27 is the first rotating shaft; 28 is the first supporting seat; 29 is the first encoder; 30 is the first servo motor; 31 is the first connection Component.

[0153] In this embodiment, both servomotors are connected to the output control terminals of the automation circuit through encoders and wires; and the automation circuit contains a computer.

[0154] In the X-Y double-axis workbench of this embodiment, there are two kinematic systems, one is the syste...

Embodiment 3

[0160] Below, combine Figure 4 Be explained. Firstly, explain the labels in the figure: 1 is the lower layer of the workbench; 2 is the middle layer of the workbench; 3 is the installation plate; 19 is the second guide rail; 20 is the first guide rail; 27 is the first rotating shaft; 28 is the first support Seat; 29 is the first encoder; 30 is the first servo motor; 32 is the front gear; 33 is the gear support; 34 is the last gear.

[0161] Such as Figure 4 As shown, the gear bracket 33 is fixedly connected with the lower layer of the workbench, the front gear 32 is fixedly connected with the output shaft of the first servo motor 30, and the last gear 34 is not only connected in rotation with the gear bracket 33, but also fixed with one end of the first rotating shaft 27 connect.

[0162] When the automation circuit sends commands to the first servo motor 30 through the first encoder 29, the following series of actions take place successively: the first servo motor 30 rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com