Circuit breaker coil automatic shaping equipment

A circuit breaker and coil technology, applied in the field of equipment that can automatically complete coil shaping, can solve the problems of low production efficiency, high labor intensity, lack of guarantee of product quality, etc., and achieve a reasonable structure, reduce labor intensity, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

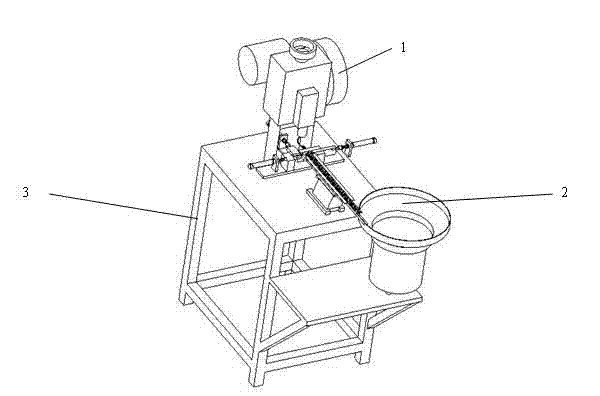

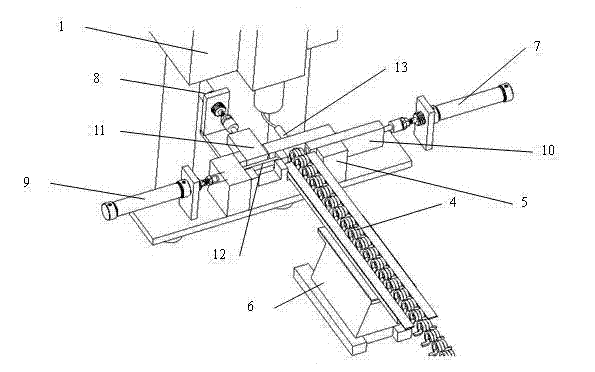

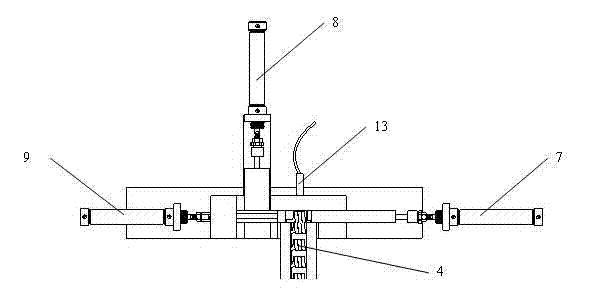

[0015] Such as figure 1 As shown in -3, the present invention includes a workbench 3 on which an automatic punching machine 1 , a fixture main board 5 and a vibrating feeder 6 are installed. The automatic punching machine 1 can be electric or pneumatic, controlled by electrical commands, and equipped with a punch that meets the process requirements. The fixture main board 5 is positioned at the bottom of the automatic punching machine 1 , and a feed slider 10 , a discharge slider 11 and a positioning rod 12 are installed on the fixture main board 5 . The feed slide block 10 is connected with the piston rod of the feed cylinder 7, the discharge slide block 11 is connected with the piston rod of the discharge cylinder 8, and the positioning rod 12 is connected with the piston rod of the positioning cylinder 9. The feeding slider 10, the positioning rod 12, the feeding cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com