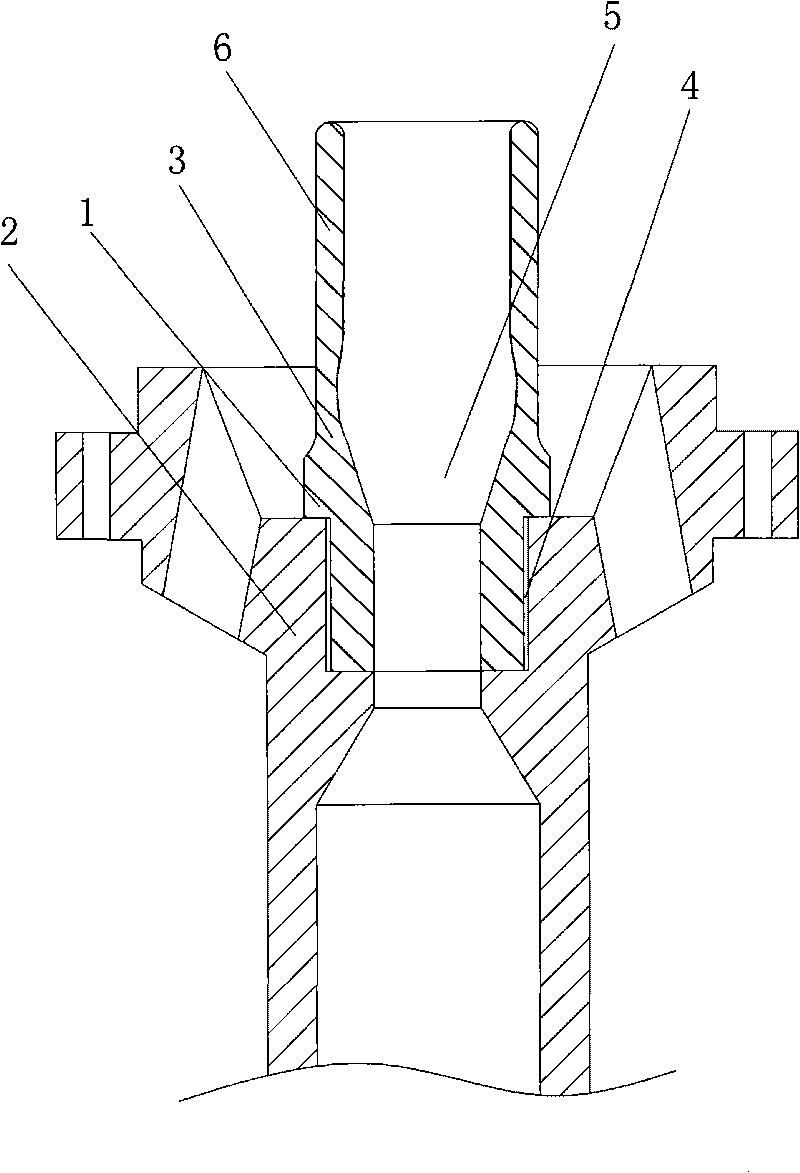

Dynamic arc contact, and installing method and special tool thereof

A technology of moving arc contacts and moving contacts, which is applied in the field of moving arc contacts, can solve problems such as the deformation of moving arc contact fingers and affect the breaking performance of circuit breakers, and achieve the goal of improving breaking performance and improving installation quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

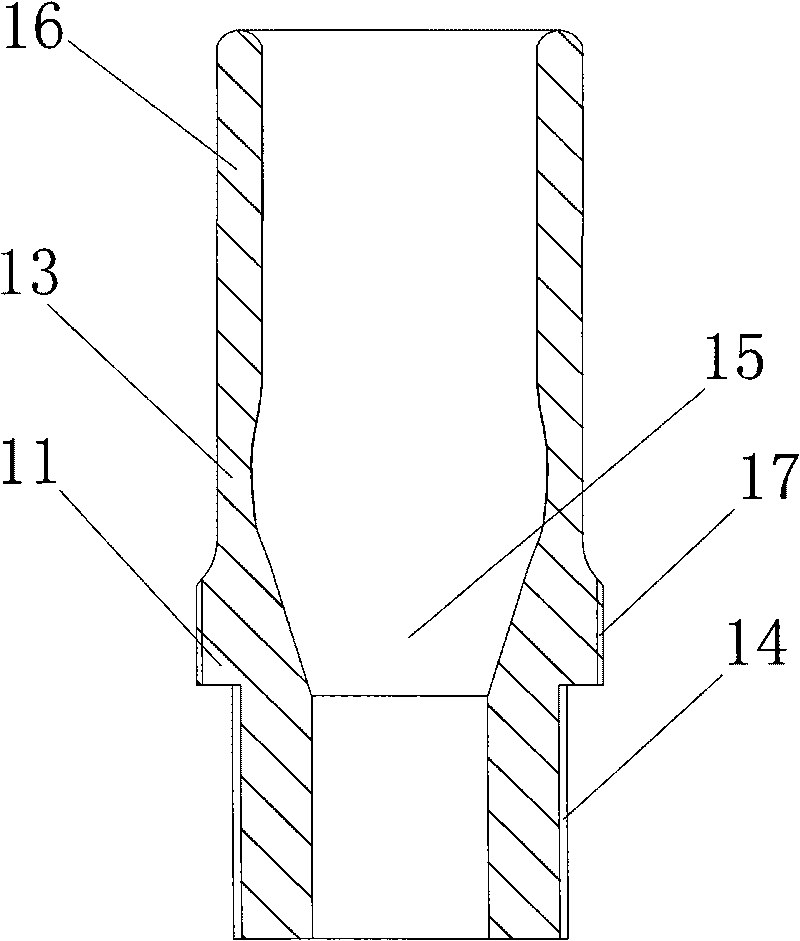

[0021] The moving arc contact of the present invention is as figure 2 As shown, it includes a tubular contact body 13, and the outer peripheral surface of the bottom end of the contact body 13 is provided with a contact thread 14, and the contact thread 14 is used for fixed connection with the moving contact; the contact at the root of the contact thread 14 The head body 13 is integrally provided with a protruding annular stopper 11 around the outer circumference. The annular stopper 11 ensures that the moving arc contact can be tightened on the moving contact. The anti-retraction thread 17 that is threadedly connected with the special tooling, the rotation direction of the anti-retraction thread 17 is the same as that of the contact thread 14; The small mouth end faces the thread direction of the contact; the upper end of the contact body 13 is the tubular contact finger 16 of the moving arc contact.

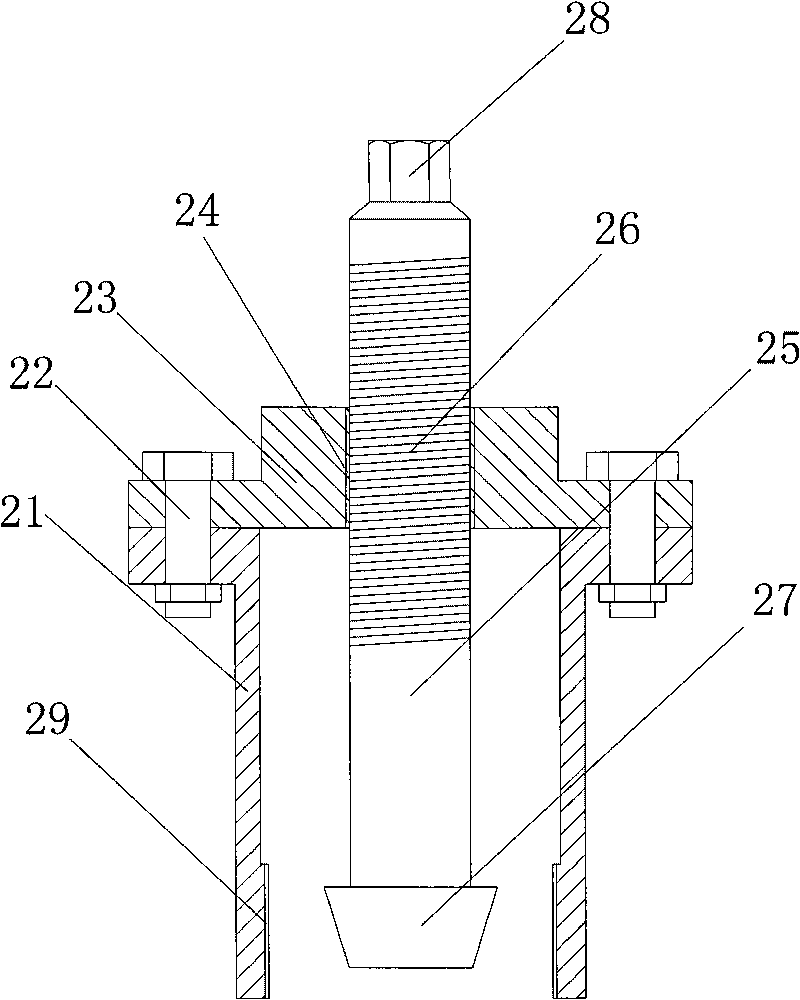

[0022] The present invention is used to install the special tooling of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com