Welding device for small circuit breaker contact plate and coil

A small circuit breaker and welding device technology, applied in the direction of emergency protection devices, emergency protection device manufacturing, circuits, etc., can solve the problems of unreliable product quality, low work efficiency, high production cost, etc., and achieve the elimination of personnel operation hazards, welding The effect of stable quality, safety and performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0047] The up, down, left, and right positions of the components described in the following text only correspond to the drawings, and the installation positions of the components in the actual structure can be deduced by analogy.

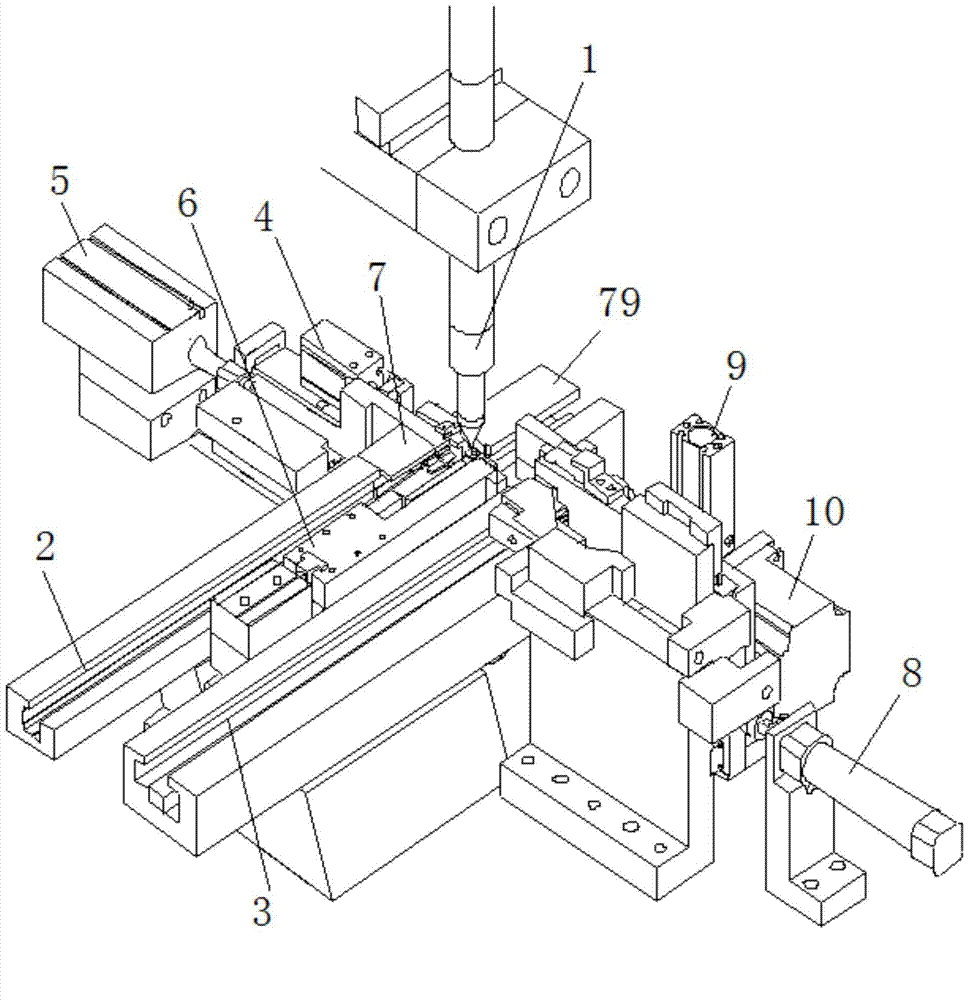

[0048] Such as figure 1 , Figure 5 , the overall structure of the present invention is that, according to the feeding processing route of the contact plate 90 and the coil 91, a feed channel, a pushing mechanism 6, a contact plate retaining mechanism 4, a contact plate feeding mechanism 5, and a coil feeding mechanism 8 are respectively provided. And coil lifting mechanism 9, electrode assembly 1 and detection mechanism 10,

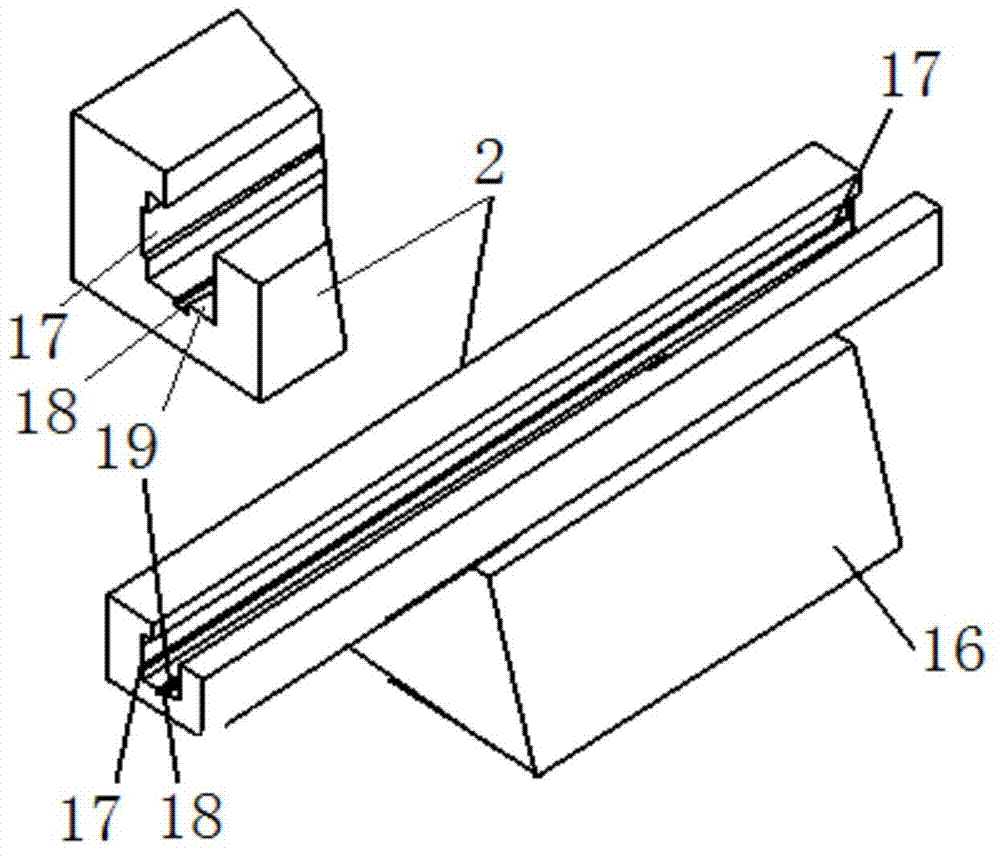

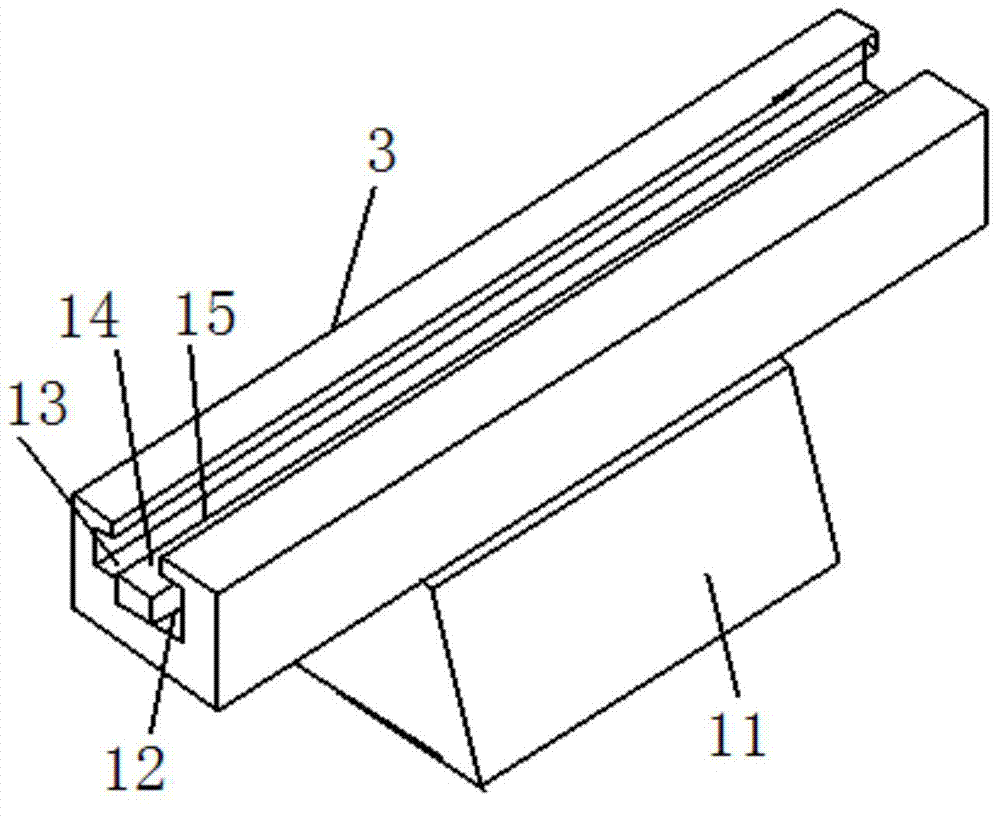

[0049] The feed channel includes a contact plate direct vibration track 2, a static material channel 7 and a coil direct vibration track 3, and the feed end of the contact plate direct vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com