Quaternary liquid metal heat interface material with dual melting points

A thermal interface material, liquid metal technology, applied in metal layered products, layered products, chemical instruments and methods, etc., can solve problems such as high fluidity and short circuit, and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

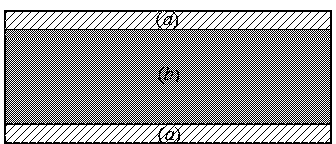

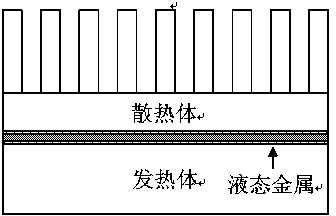

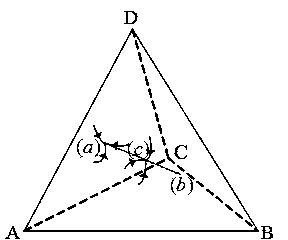

[0016] For the quaternary liquid metal thermal interface material composed of In-Bi-Sn-Zn, the composition of the upper and lower layers is selected as In0.50-0.18Bi-0.24Sn-0.08Zn (mole fraction). The material of the middle layer is In0.33-0.26Bi-0.29Sn-0.12Zn (mole fraction). The alloy prepared according to this formula is melted in a vacuum induction furnace and prepared into a three-layer foil structure. The thickness of the upper and lower layers is 0.01mm. The thickness of the intermediate layer was 0.03 mm. Then the three-layer foil-like alloy material is combined into a liquid metal thermal interface material with a sandwich structure, with a melting point of about 100 °C, as figure 1 shown. They are upper and lower layers (a) with lower melting point and middle layer (b) with higher melting point, respectively. The present invention selects elements with sufficient chemical compatibility with the materials of the heating element and the radiator from the periodic tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com