A ternary liquid metal thermal interface material with dual melting point characteristics

A thermal interface material, liquid metal technology, applied in the direction of heat exchange materials, electrical components, semiconductor/solid-state device components, etc., can solve problems such as high fluidity and short circuit, and achieve the effect of broad application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

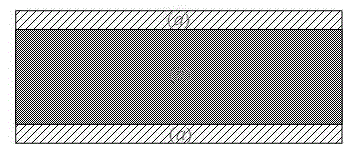

[0013] For the ternary liquid metal thermal interface material composed of In-Bi-Sn, the composition of the upper and lower layers is selected as In0.56-0.20Bi-0.24Sn (mole fraction). The material of the middle layer is In0.40-0.48Bi-0.12Sn (mole fraction). The alloy prepared according to this formula is melted in a vacuum induction furnace and prepared into a three-layer foil structure. The thickness of the upper and lower layers is 0.01mm, and the thickness of the middle layer is The thickness is 0.03mm. Then the three-layer foil-like alloy material is combined into a liquid metal thermal interface material with a sandwich structure, and the highest melting point is around 90°C. Such as figure 1 Shown are the upper and lower layers (a) with a lower melting point and the middle layer (b) with a higher melting point, respectively.

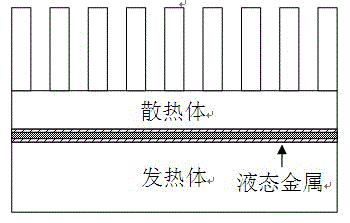

[0014] The present invention selects elements with sufficient chemical compatibility with the materials of the heating element and the radiator ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com