Gas cupola for melting metal

A cupola and metal technology, applied in the field of gas-fired cupolas for metal melting, can solve problems such as a large amount of coke, and achieve the effect of reducing the amount of use and efficient melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

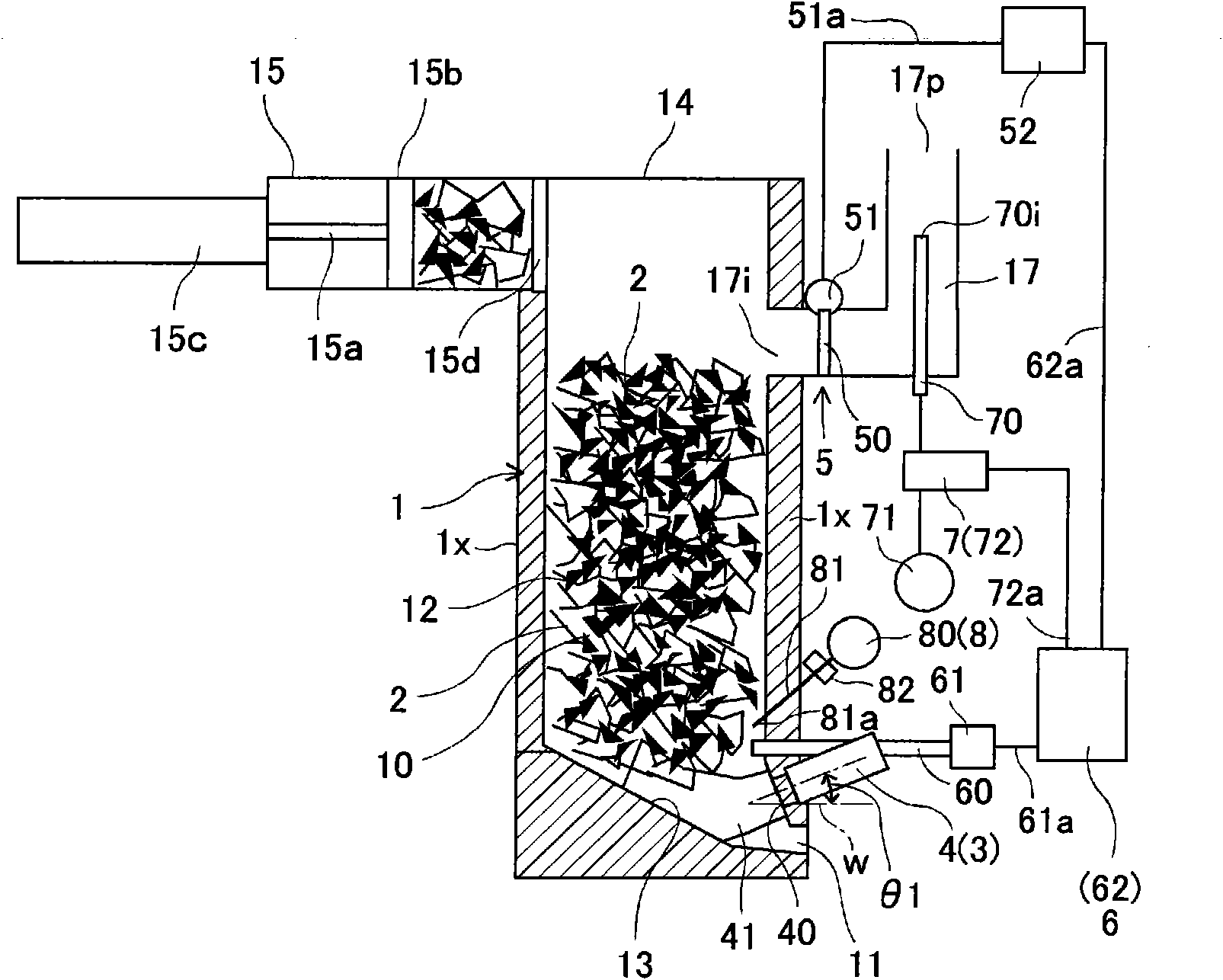

[0029] like figure 1 As shown, the gas-fired cupola for metal melting in this embodiment is used to form a cast iron melt, and includes a cylindrical furnace body 1 and a burner group 3 installed in the furnace body 1 . Examples of cast iron include flaky graphite cast iron, nodular graphite cast iron, and vermicular graphite cast iron. The body of furnace 1 is a vertical device along the direction of gravity. The body of furnace 1 is provided with a melting chamber 10 and a melt outlet 11. The melting chamber 10 is used to melt the charge 2 with metal as the base material. 11 is used to discharge the melt formed after the charge 2 is melted in the melting chamber 10 . A portion on the upper side in the melting chamber 10 is formed as a preheating belt 12 for preheating the charge 2 . A melt discharge port 11 is formed near the bottom of the furnace body 1 . On the bottom side of the melting chamber 10 , a hearth surface 13 that slopes down toward the melt outlet 11 side is...

Embodiment approach 2

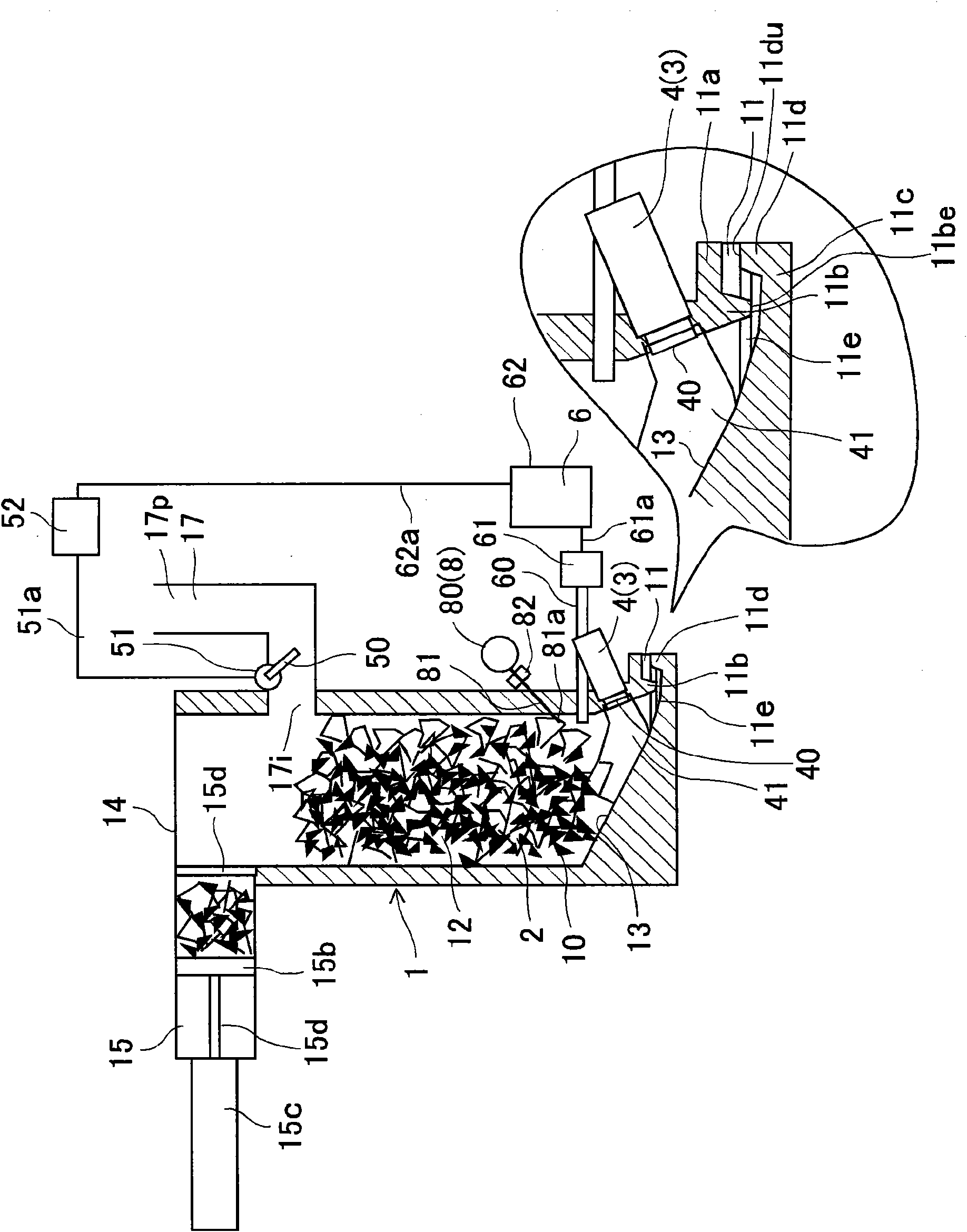

[0053] image 3 Embodiment 2 of this invention is shown. This embodiment basically has the same structure and effects as the above-mentioned embodiment. The melt outlet 11 includes an upper wall 11a, a lower wall 11c, a siphon partition wall 11b protruding downward from the upper wall 11a at the melt outlet 11, and an outlet intercepting portion protruding upward from the lower wall 11c. 11d, and the siphon liquid storage space 11e. In this way, the melt discharge port 11 is formed as an external air entry prevention structure capable of preventing external air from entering the melting chamber 10, and is a siphon structure, and the upper end 11du of the outlet blocking portion 11d is located closer to the lower end 11be of the siphon partition wall 11b than the lower end 11be of the siphon partition wall 11b. position above.

[0054] Since the melt stays in the siphon liquid storage space 11e and is held in this space, it is possible to improve the isolation and airtightne...

Embodiment approach 3

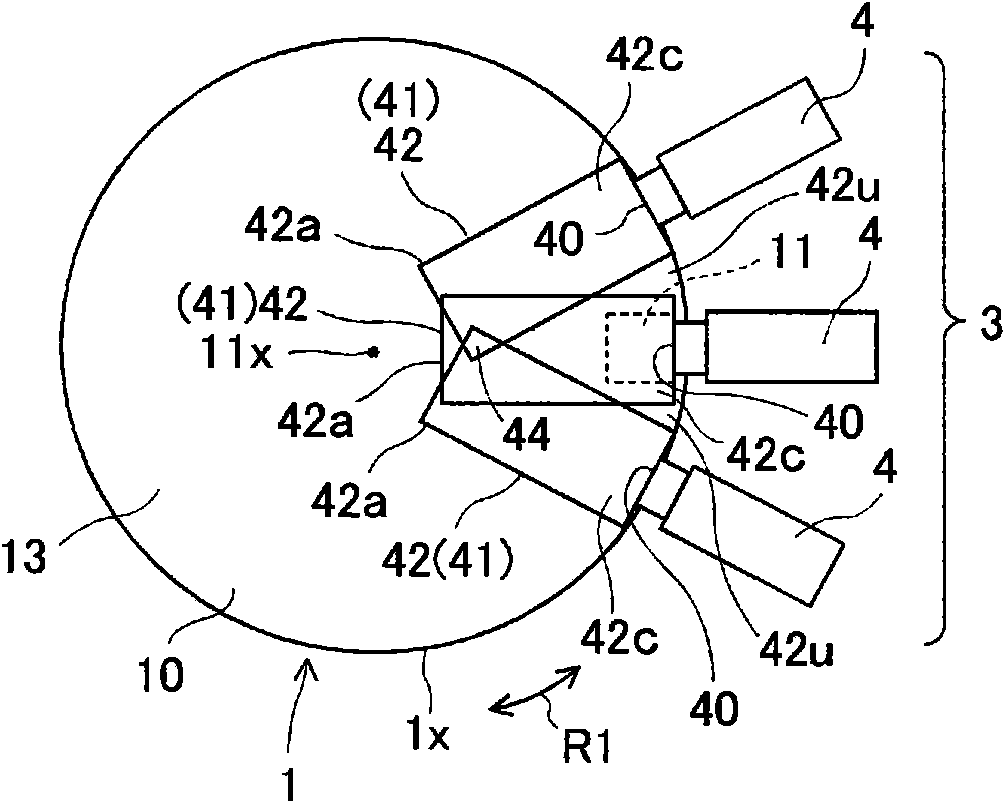

[0056] Figure 4 Embodiment 3 of this invention is shown. Figure 4 A cross-sectional view obtained by cutting the furnace body 1 in the horizontal direction is shown. like Figure 4 As shown, a plurality of burners 4 constituting the burner group 3 are arranged in a fan shape with respect to the center line 11x of the melting chamber 10 in the radial direction. The plurality of burners 4 are not arranged over the entire circumference in the circumferential direction (arrow R1 direction) around the center line 11x.

[0057] A hollow melting portion 42 having a cylindrical shape or a hollow shape similar to a cylinder is generated in the charge 2 of the melting chamber 10 by the combustion flame 41 discharged from the burner 4 . exist Figure 4 The hollow melting part 42 is roughly shown in . The burner 4 is arranged so that the front end portions 42a of the plurality of adjacent hollow melting portions 42 of the burner 4 overlap with each other.

[0058] As a result, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com