A graphite crucible for silicon electromagnetic induction heating and apparatus for silicon melting and refining using the graphite crucible

一种石墨坩埚、电磁感应的技术,应用在自区域熔融法、自熔融液提拉法、单晶生长等方向,能够解决难制作等问题,达到消除熔液和石墨接触、高效硅电磁感应熔融的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1, Embodiment 2

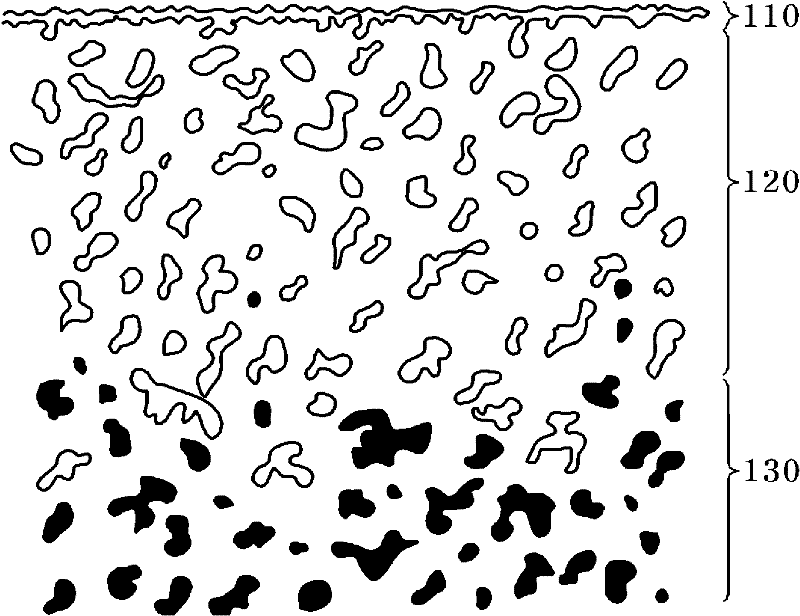

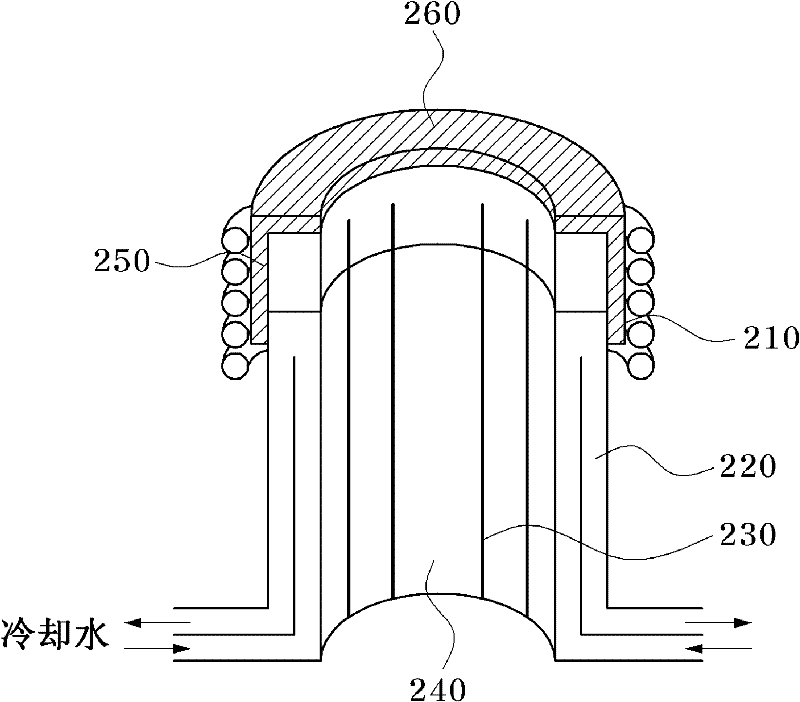

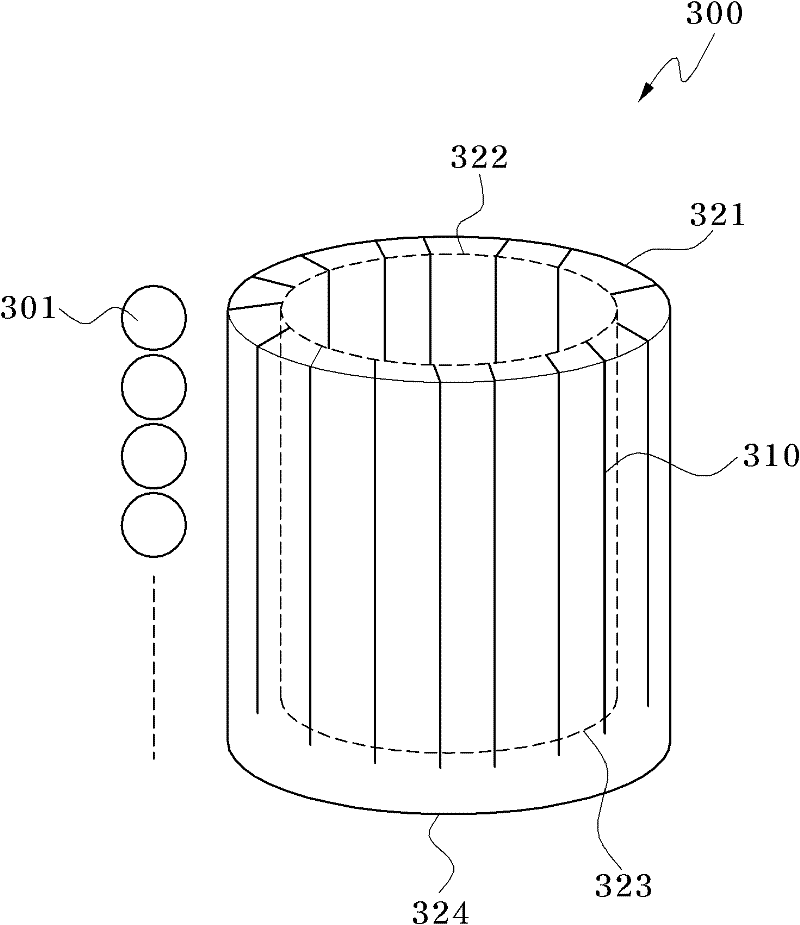

[0050] In a graphite crucible with a height of 90 mm, an inner diameter of 60 mm, and an outer diameter of 80 mm, 12 (Example 1) and 24 (Example 2) slits with a slit width of 1 mm were formed in a symmetrical structure, and the above-mentioned slits were formed to the bottom plate . At this time, high-density graphite having a density of 1.75 or higher was used as the graphite to be used. On the outside of the above-mentioned crucible, 8 turns of water-cooled induction coils with a diameter of 8 mm are wound to make it have an inner diameter of 100 mm and an outer diameter of 1200 mm. At this time, the interval between the water-cooled coils is 1-2 mm. An alternating current with a frequency of 6 to 10 kHz at a maximum of 30 kW is input to this coil.

[0051] Fill the crucible with silicon chunks (chunk) with a purity of 99.5% and a size of 1 to 10 mm, and form 10 -3 ~10 -5 After the base pressure (base pressure) of Torr, fill Ar and under the working pressure (working pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com