Non-backed-up packing element system

a packing element and non-backed-up technology, applied in the direction of sealing/packing, fluid removal, borehole/well accessories, etc., can solve the problems of increasing the cost of running and setting these prior packing element systems, and achieve the effect of effective sealing a casing string, less axial loading, and reduced cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

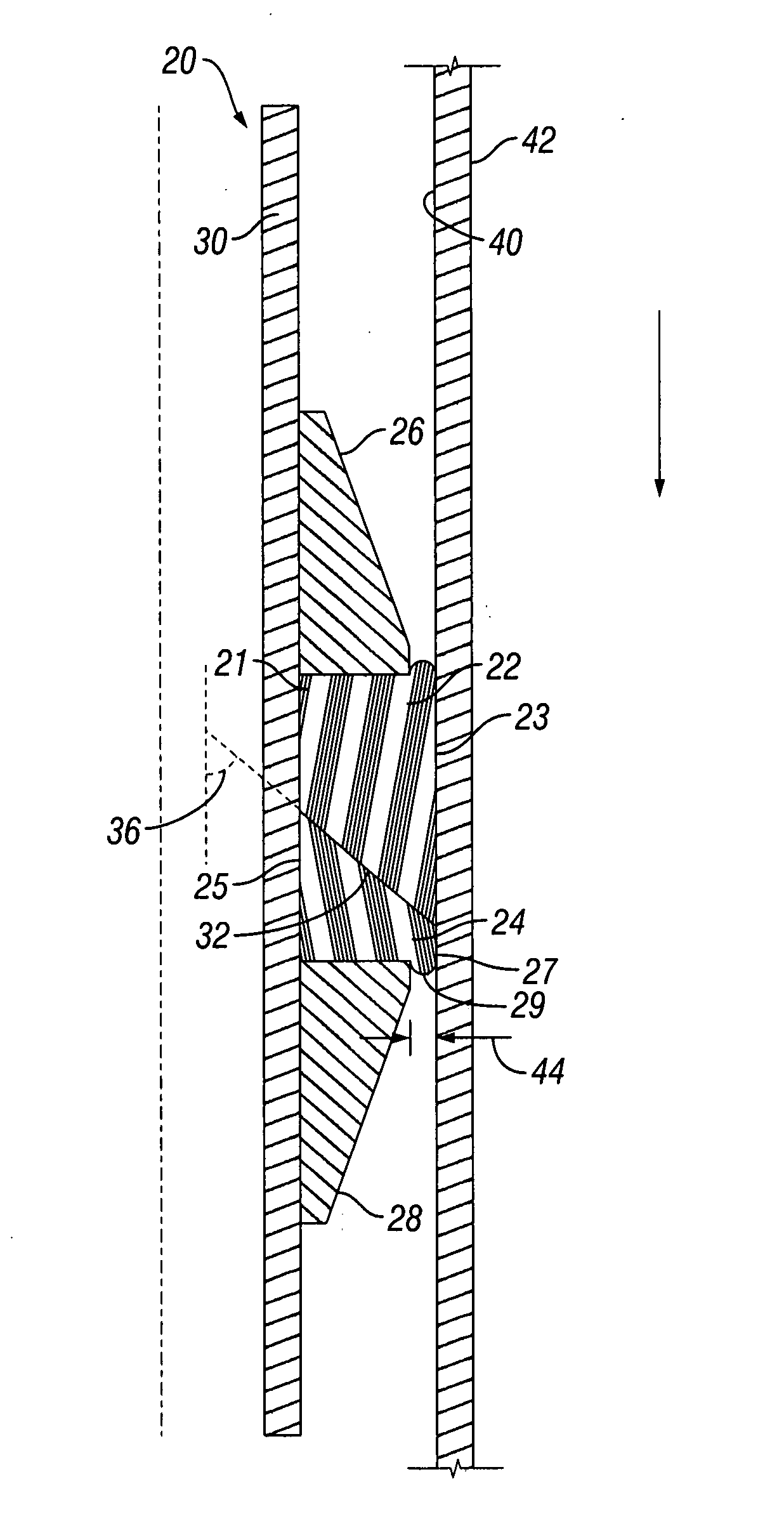

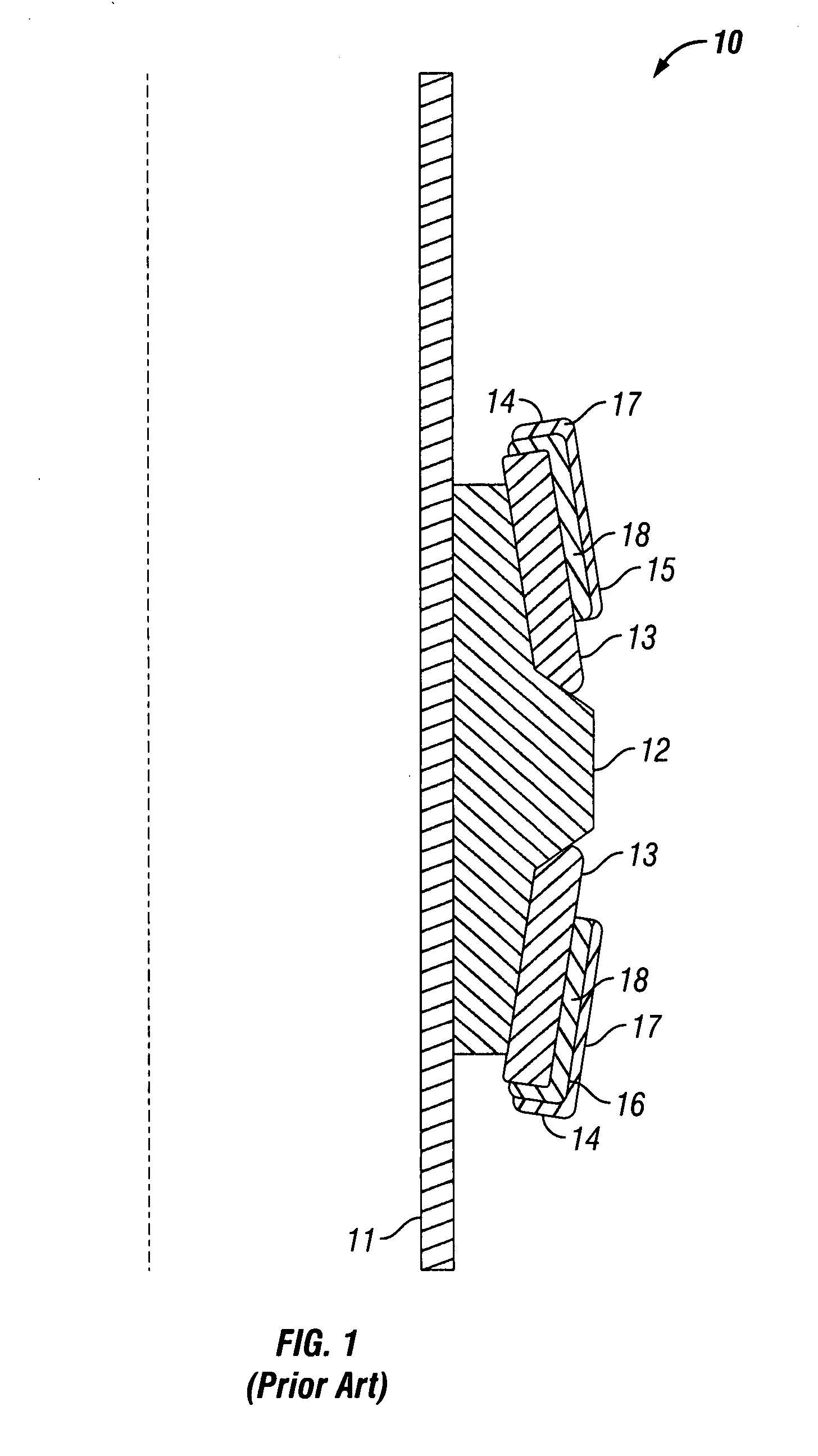

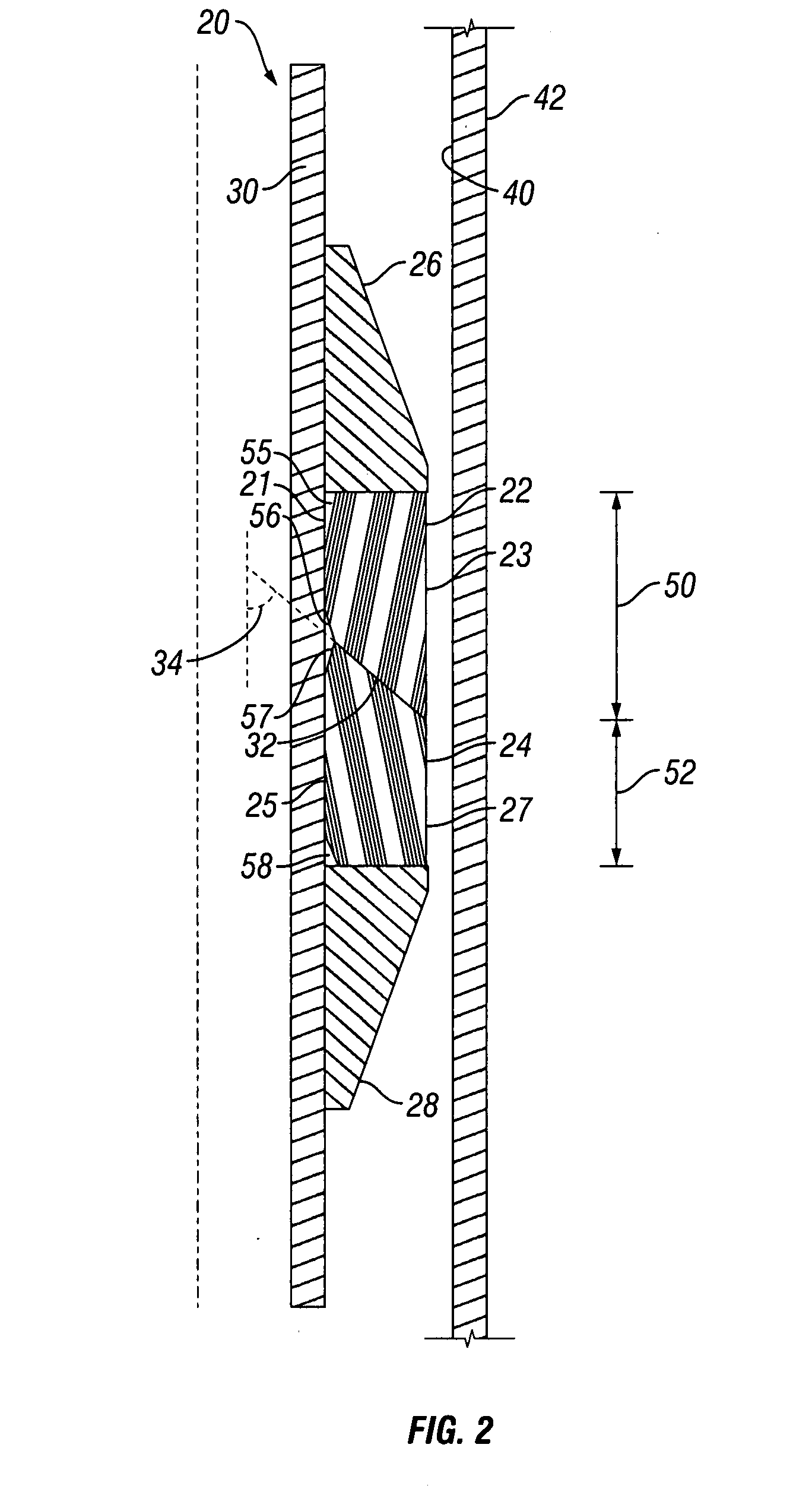

[0023]Referring now to FIGS. 2-3, packing element system 20 is shown in its initial or run-in position (FIG. 2) and its set position (FIG. 3). Broadly, packing element system 20 includes five components or parts: cantilever element 22, ramp element 24, upper cone 26, and lower cone 28, all carried on mandrel 30. Cantilever element 22, ramp element 24, upper cone 26, and lower cone 28 are tubular members, each having an inner surface determined by an inner diameter that receives mandrel 30. As will be appreciated by persons of ordinary skill in the art, mandrel 30 is a tubular member carried on a casing string (not shown). Mandrel 30 can be secured to the casing string through any device or method known to persons of ordinary skill in the art. No back-up component such as component 15 shown in FIG. 1 is required.

[0024]Cantilever element 22 is a deformable element formed from a deformable material that is in contact with ramp element 24 at interface 32. Ramp element 24 also is a defor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com