Tape casting slurry for laminated sheet type electronic component and preparation method for tape casting slurry

A technology for electronic components and casting slurry, which is applied to the field of casting slurry for laminated chip electronic components and its production, can solve the problem of increase in slurry viscosity, increase in green density of membrane, deterioration in membrane performance, etc. problem, to achieve the effect of enhanced ductility, increased density, and excellent dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

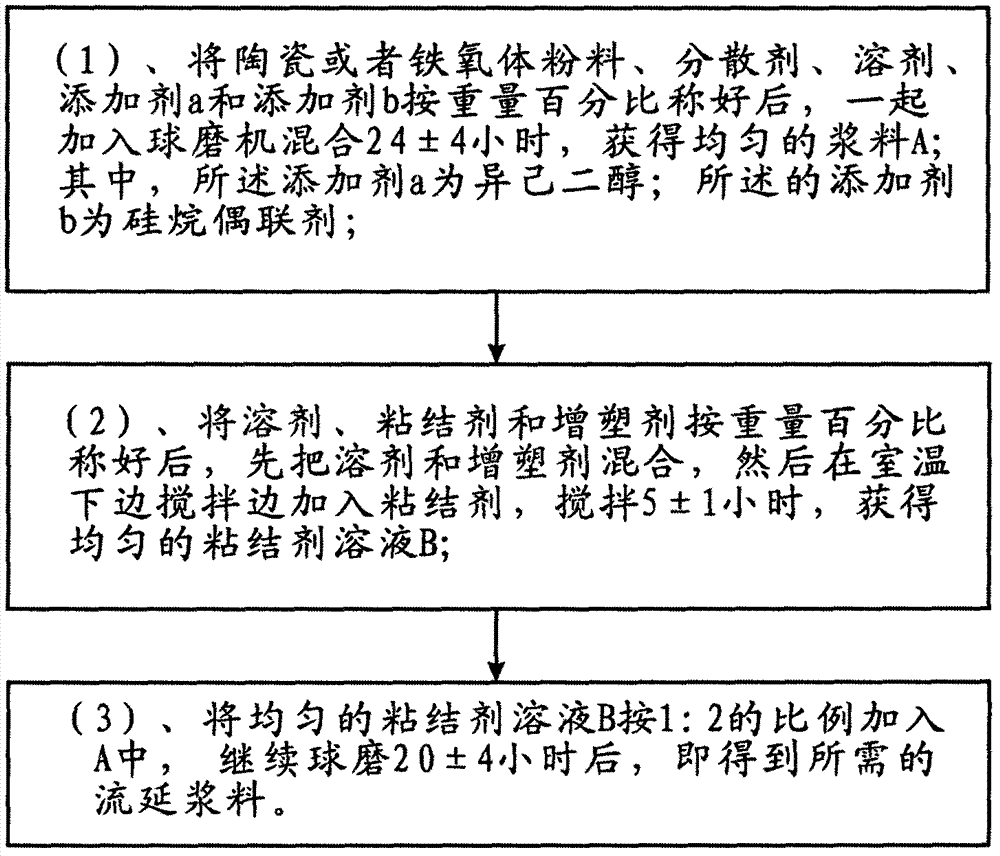

Method used

Image

Examples

Embodiment 1

[0035] A, by weight percentage ceramic powder 75%, castor oil 0.2%, ethanol 14.64%, butanone 9.76%, isohexanediol 0.2% and silane coupling agent 0.2% weighed by weight percentage, add ball mill together and mix 24 ±4 hours to obtain a uniform slurry;

[0036] B. After weighing 42.0% of ethanol, 28.0% of methyl ethyl ketone, 20% of polyvinyl butyral, 5% of triethylene glycol diisocaprylate and 5% of glycerol, the solvent and plasticizer Mix the binder, then add the binder while stirring at room temperature, and stir for 5±1 hours to obtain a uniform binder solution;

[0037] C. Add uniform binder solution B into A at a ratio of 1:2, and continue ball milling for 20±4 hours to obtain the casting slurry required by the patent;

[0038] D. Tape-cast the prepared slurry and dry at 50-60° C. for 5±1 minutes.

Embodiment 2

[0040] A. 70% by weight of ceramic powder, 0.3% of fish oil, 24.23% of propyl acetate, 4.97% of isobutanol, 0.4% of isohexanediol and 0.1% of silane coupling agent are weighed by weight, and then added to the ball mill for mixing 24±4 hours to obtain a uniform slurry;

[0041]B. After weighing 58.10% of propyl acetate, 11.90% of isobutanol, 18% of polyvinyl butyral, 8% of dioctyl phthalate and 4% of glycerol, the solvent and Mix the plasticizer, then add the binder while stirring at room temperature, and stir for 5±1 hours to obtain a uniform binder solution;

[0042] C. Add uniform binder solution B into A at a ratio of 1:2, and continue ball milling for 20±4 hours to obtain the casting slurry required by the patent;

[0043] D. Tape-cast the prepared slurry and dry at 55-80° C. for 5±1 minutes.

Embodiment 3

[0045] A. Ferrite powder 80% by weight, polyethylene glycol octyl phenyl ether 0.4%, ethanol 11.88%, butanone 6.92%, isohexanediol 0.5% and silane coupling agent 0.3% by weight After weighing, add it to the ball mill and mix for 24±4 hours to obtain a uniform slurry;

[0046] B. After weighing 45.0% ethanol, 30.0% methyl ethyl ketone, 19% polyvinyl butyral and 6% dibutyl phthalate by weight percentage, first mix the solvent and plasticizer, and then mix the solvent and plasticizer at room temperature Add the binder while stirring, and stir for 5±1 hours to obtain a uniform binder solution;

[0047] C. Add uniform binder solution B into A at a ratio of 1:2, and continue ball milling for 20±4 hours to obtain the casting slurry required by the patent;

[0048] D. Tape-cast the prepared slurry and dry at 50-60° C. for 5±1 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com