Heat stabilizer for PVC plastic production and processing

A thermal stabilizer and plastic technology, applied in the field of new functional materials, can solve the problems of PVC plastics with poor service life, poor thermal stability of PVC plastics, and limited application range, and achieve aging resistance and mechanical properties. Effect of compatibility, high mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

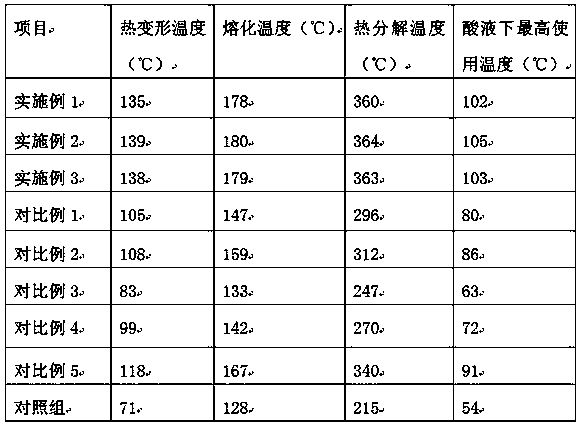

Examples

Embodiment 1

[0019] A heat stabilizer for the production and processing of PVC plastics, made of the following components in parts by weight: 1.8 parts of zinc oxide, 1.5 parts of holmium oxide, 11 parts of sodium hydroxide solution, 0.5 parts of oleic acid, 20 parts of ethanol, n-heptane 3.2 parts, 1.0 parts of triethylenetetramine, 1.2 parts of nitrogen nitrogen dimethylformamide, 5.5 parts of zeolite powder, 3 parts of concentrated ammonia water, and its preparation method comprises the following steps:

[0020] (1) Add zinc oxide and holmium oxide powder into a beaker, add sodium hydroxide solution, stir and mix evenly, then transfer to a three-necked flask equipped with a stirrer, drop oleic acid, stir quickly and mix evenly, heat in a water bath to 45°C, Then add n-heptane and nitrogen nitrogen dimethylformamide into the three-necked flask, continue to heat up to 85 ° C, stir and react for 2 hours, and cool to room temperature after the reaction;

[0021] (2) Add zeolite powder to et...

Embodiment 2

[0029] A heat stabilizer for the production and processing of PVC plastics, made of the following components in parts by weight: 1.9 parts of zinc oxide, 1.55 parts of holmium oxide, 11.5 parts of sodium hydroxide solution, 0.55 parts of oleic acid, 23 parts of ethanol, n-heptane 3.25 parts, 1.1 parts of triethylenetetramine, 1.3 parts of nitrogen nitrogen dimethylformamide, 5.8 parts of zeolite powder, 3.5 parts of concentrated ammonia water, and its preparation method comprises the following steps:

[0030] (1) Add zinc oxide and holmium oxide powder into a beaker, add sodium hydroxide solution, stir and mix evenly, then transfer to a three-necked flask equipped with a stirrer, drop oleic acid, stir quickly and mix evenly, heat in a water bath to 50°C, Then add n-heptane and nitrogen nitrogen dimethylformamide into the three-necked flask, continue to heat up to 86 ° C, stir and react for 2.5 hours, and cool to room temperature after the reaction;

[0031] (2) Add zeolite pow...

Embodiment 3

[0039] A heat stabilizer for PVC plastic production and processing, made of the following components in parts by weight: 2.0 parts of zinc oxide, 1.6 parts of holmium oxide, 12 parts of sodium hydroxide solution, 0.6 parts of oleic acid, 25 parts of ethanol, n-heptane 3.3 parts, 1.2 parts of triethylenetetramine, 1.4 parts of nitrogen nitrogen dimethylformamide, 6.0 parts of zeolite powder, 4 parts of strong ammonia water, and its preparation method comprises the following steps:

[0040] (1) Add zinc oxide and holmium oxide powder into a beaker, add sodium hydroxide solution, stir and mix evenly, then transfer to a three-necked flask equipped with a stirrer, drop oleic acid, stir quickly and mix evenly, heat in a water bath to 55°C, Then add n-heptane and nitrogen nitrogen dimethylformamide into the three-necked flask, continue to heat up to 88 ° C, stir and react for 3 hours, and cool to room temperature after the reaction;

[0041](2) Add zeolite powder to ethanol solvent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com