Method for improving aging resistance of high-density polyethylene plastic

A high-density polyethylene, aging-resistant technology, applied in the field of improving the aging resistance of high-density polyethylene plastics, to achieve high mechanical stability, aging resistance and mechanical properties improvement, and improve the effect of development and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

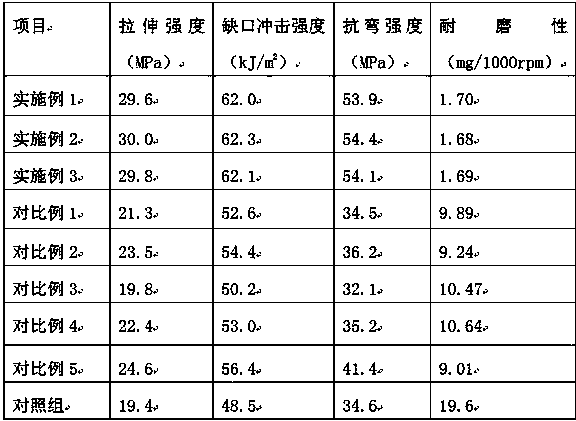

Examples

Embodiment 1

[0018] A method for improving the aging resistance of high-density polyethylene plastics, comprising the steps of:

[0019] (1) Mix fine silica aerogels with a particle size between 15-45 nanometers and basalt fibers at a mass ratio of 2.8:1.0, place them in steam at 150°C for 10 minutes under pressure, Then place it in an oven at 70°C and dry it for 8 hours. The dried mixture is put into a preheated muffle furnace for calcination. Processed nanomaterials;

[0020] (2) Dry the titanium dioxide powder in a vacuum oven at 80°C for 2 hours, then add it to a three-necked flask, use ethylenediamine and absolute ethanol as a solvent in a mass ratio of 1:4, and add it to the flask, The mixing mass ratio of material to liquid is 1:12, ultrasonically dispersed for 20 minutes, then heated in a water bath to 55°C, turned on the stirrer to stir, and added graphene oxide accounting for 2.3% of the mass of titanium dioxide powder, and at the same time, added dropwise chlorine that was 1.9 ...

Embodiment 2

[0028] A method for improving the aging resistance of high-density polyethylene plastics, comprising the steps of:

[0029] (1) Mix fine silica airgel with a particle size between 15-45 nanometers and basalt fiber at a mass ratio of 2.9:1.1, place in steam at 165°C for 12 minutes under pressure, Then place it in an oven at 75°C for 9 hours, put the dried mixture into a preheated muffle furnace for calcination. Processed nanomaterials;

[0030] (2) Dry the titanium dioxide powder in a vacuum oven at 82°C for 2.5 hours, then add it to a three-necked flask, use ethylenediamine and absolute ethanol as a solvent in a mass ratio of 1:4.5, and add it to the flask, The mixing mass ratio of material to liquid is 1:13, ultrasonically dispersed for 25 minutes, then heated in a water bath to 58°C, turned on the stirrer to stir, and added graphene oxide accounting for 2.4% of the mass of titanium dioxide powder, and at the same time, added dropwise chlorine that was 1.95 times the volume ...

Embodiment 3

[0038] A method for improving the aging resistance of high-density polyethylene plastics, comprising the steps of:

[0039] (1) Mix fine silica airgel with a particle size between 15-45 nanometers and basalt fiber at a mass ratio of 3.0:1.2, place in steam at 180°C for 14 minutes under pressure, Then place it in an oven at 80°C for 10 hours, put the dried mixture into a preheated muffle furnace for calcination. Processed nanomaterials;

[0040] (2) Dry the titanium dioxide powder in a vacuum oven at 85°C for 3 hours, then add it to a three-necked flask, use ethylenediamine and absolute ethanol as a solvent in a mass ratio of 1:5, and add it to the flask, The mixing mass ratio of material to liquid is 1:14, ultrasonically dispersed for 30 minutes, then heated in a water bath to 60°C, turned on the stirrer to stir, and added graphene oxide accounting for 2.5% of the mass of titanium dioxide powder, and at the same time added dropwise chlorine that was 2.0 times the volume of ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com