Method for preparing high-performance autoclaved aerated concrete blocks through graphite tailings

A technology for concrete blocks and graphite tailings, which is applied in the field of building materials to achieve the effects of reducing energy consumption of ball milling, accurate size and shortening of ball milling time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing a high-performance autoclaved aerated concrete block by using graphite tailings, the method comprises the following steps:

[0029] Step 1: Pretreatment of graphite tailings: after adding waste silicate glass with a mass percentage of 5% to the graphite tailings, ball mill for 5 minutes;

[0030] The fineness after ball milling of waste silicate glass is controlled at 0.08mm, and the sieve residue is 10-15%;

[0031] Step 2: Mixing and stirring: Mix the graphite tailings pretreated in step 1 with quicklime, cement, gypsum, aluminum powder, admixture and water in a certain proportion for 100 seconds until evenly stirred to make a uniformly stirred slurry;

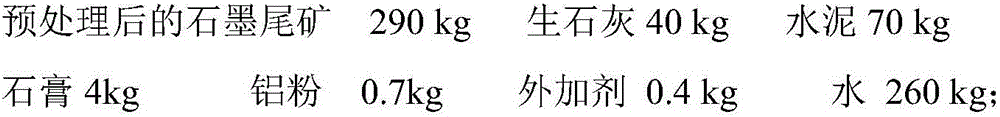

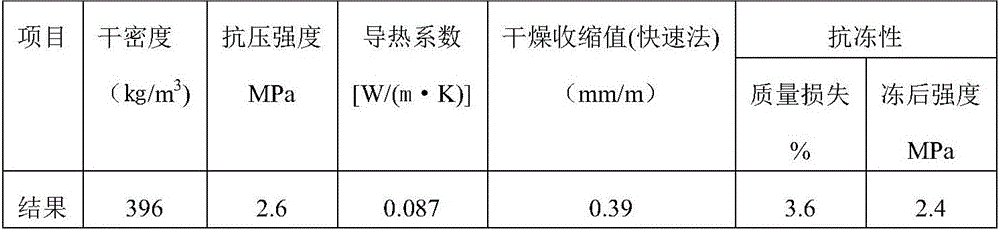

[0032] The proportioning ratio of each component that makes every cubic meter of autoclaved aerated concrete block is:

[0033]

[0034] Step 3: pouring, gas generation, static stop: pour the uniformly stirred slurry prepared in step 2 into the mold, vibrate for 8 seconds, enter the pre-curi...

Embodiment 2

[0050] A method for preparing a high-performance autoclaved aerated concrete block by using graphite tailings, the method comprises the following steps:

[0051] Step 1: Pretreatment of graphite tailings: ball mill graphite tailings for 3 minutes;

[0052] After ball milling, the fineness is controlled at 0.08mm, and the sieve residue is 10-15%;

[0053] Step 2: Mixing and stirring: mix the graphite tailings pretreated in step 1 with quicklime, cement, gypsum, aluminum powder, admixture and water in a certain proportion for 80 seconds until evenly stirred to make a uniformly stirred slurry;

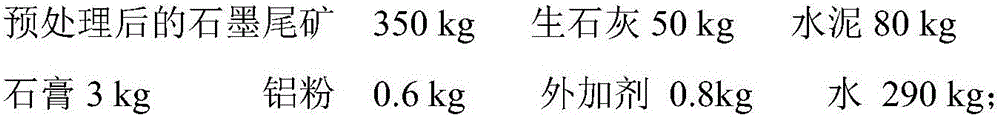

[0054] The proportioning ratio of each component that makes every cubic meter of autoclaved aerated concrete block is:

[0055]

[0056] Step 3: pouring, gas generation, static stop: pour the evenly stirred slurry prepared in step 2 into the mold, vibrate for 10s, enter the pre-curing room, maintain at a temperature of 50°C, generate gas, stop for 2.5 hours, and make Obtain pre-cured b...

Embodiment 3

[0072] A method for preparing a high-performance autoclaved aerated concrete block by using graphite tailings, the method comprises the following steps:

[0073] Step 1: Pretreatment of graphite tailings: after mixing waste silicate glass with a mass percentage of 3% into the graphite tailings, ball mill for 4 minutes;

[0074] The fineness after ball milling of waste silicate glass is controlled at 0.08mm, and the sieve residue is 10-15%;

[0075] Step 2: Mixing and stirring: mix the graphite tailings pretreated in step 1 with quicklime, cement, gypsum, aluminum powder, admixture and water in a certain proportion for 90 seconds until evenly stirred to make a uniformly stirred slurry;

[0076] The proportioning ratio of each component that makes every cubic meter of autoclaved aerated concrete block is:

[0077]

[0078] Step 3: pouring, gas generation, static stop: pour the uniformly stirred slurry prepared in step 2 into the mold, vibrate for 9s, enter the pre-curing roo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com