Method for preparing ferric phosphate lithium anode material combining solid and liquid

A technology of lithium iron phosphate and positive electrode material, applied in chemical instruments and methods, structural parts, battery electrodes, etc., can solve problems such as high cost, unfavorable environmental protection, uneven mixing, etc., to improve electrochemical performance and improve electronic conductivity , the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

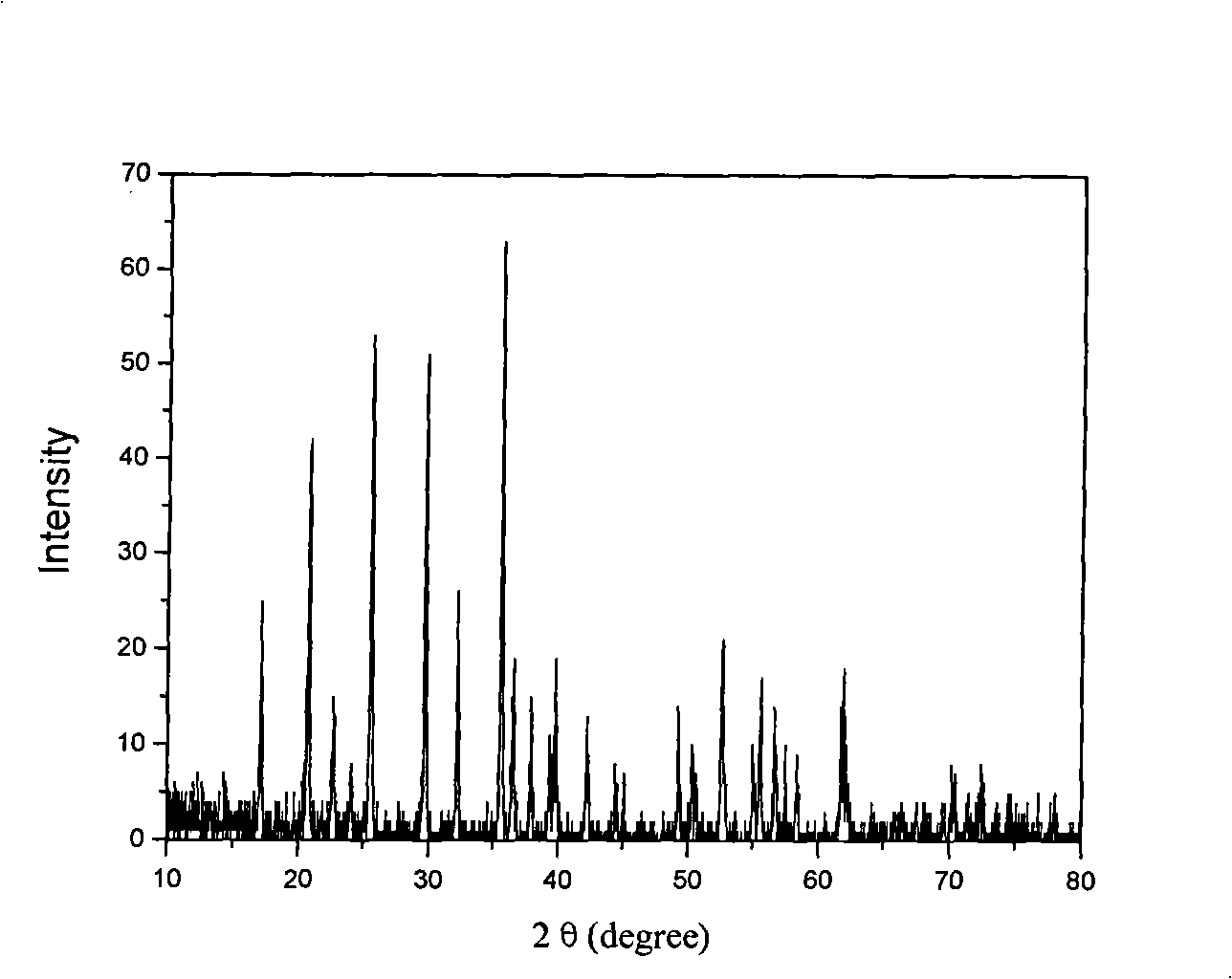

[0023] Weigh 3.7318g (0.05mol) of lithium carbonate, 8.4053g (0.05mol) of ferric oxide, 4.6477g (0.04mol) of ammonium dihydrogen phosphate, 4.1ml of 85% phosphoric acid and 2.17g (0.012mol) of glucose. Put it in a mortar and mix evenly, grind it for 10 minutes, put it in an oven and dry it at 100°C, take it out and use a star ball mill to grind it for 10 minutes, put the mixture in a tube furnace, and blow it with an inert gas for 3-5 minutes. The air in the reactor was exhausted and sealed; raised to 650°C at 15°C / min, kept at a constant temperature for 6 hours, then naturally cooled to room temperature and taken out to obtain lithium iron phosphate (LiFePO 4 / C) The material is 15.2 grams. figure 1 It is an X-ray diffraction pattern, and the analysis shows that the obtained lithium iron phosphate powder is a pure olivine-type orthorhombic single-phase structure.

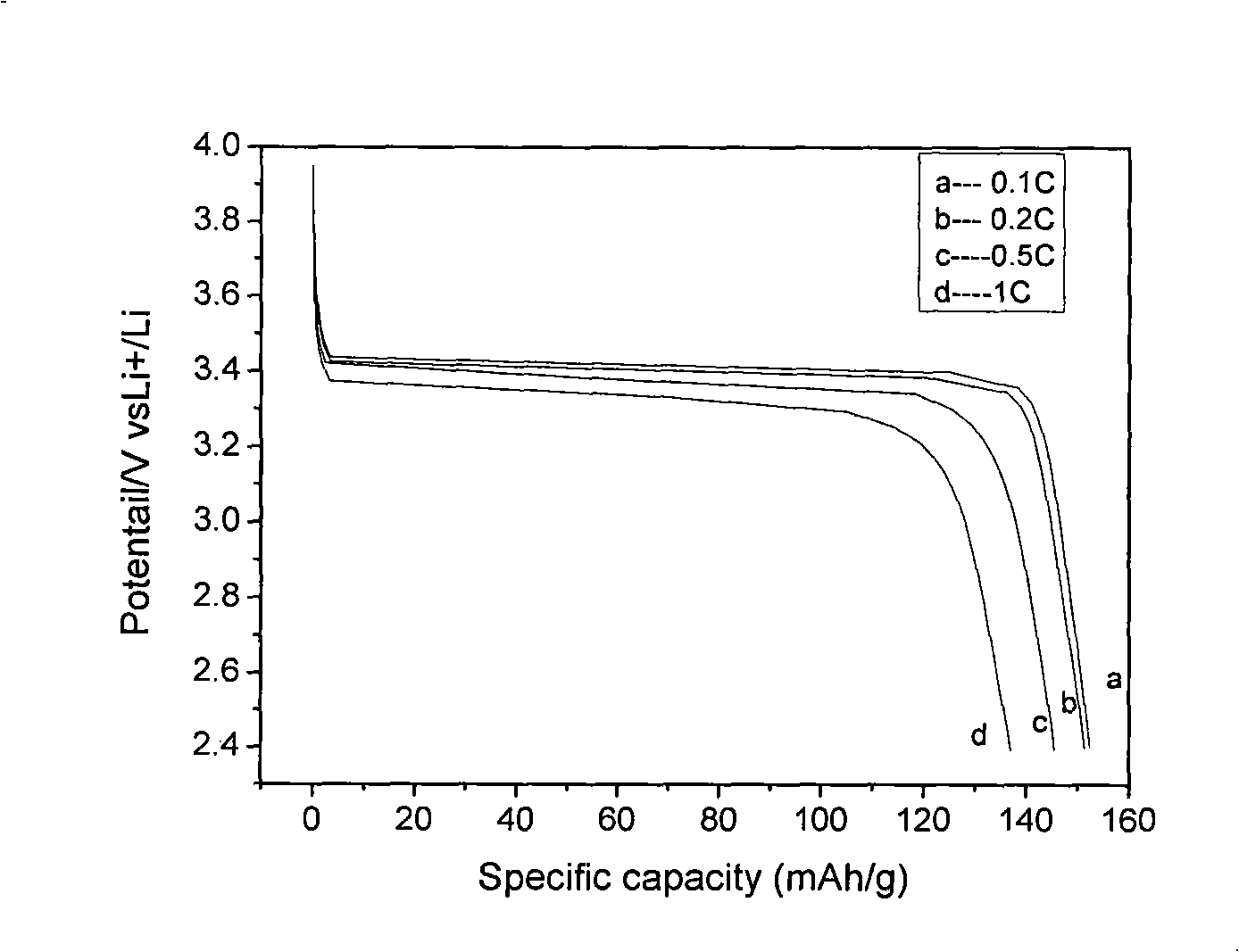

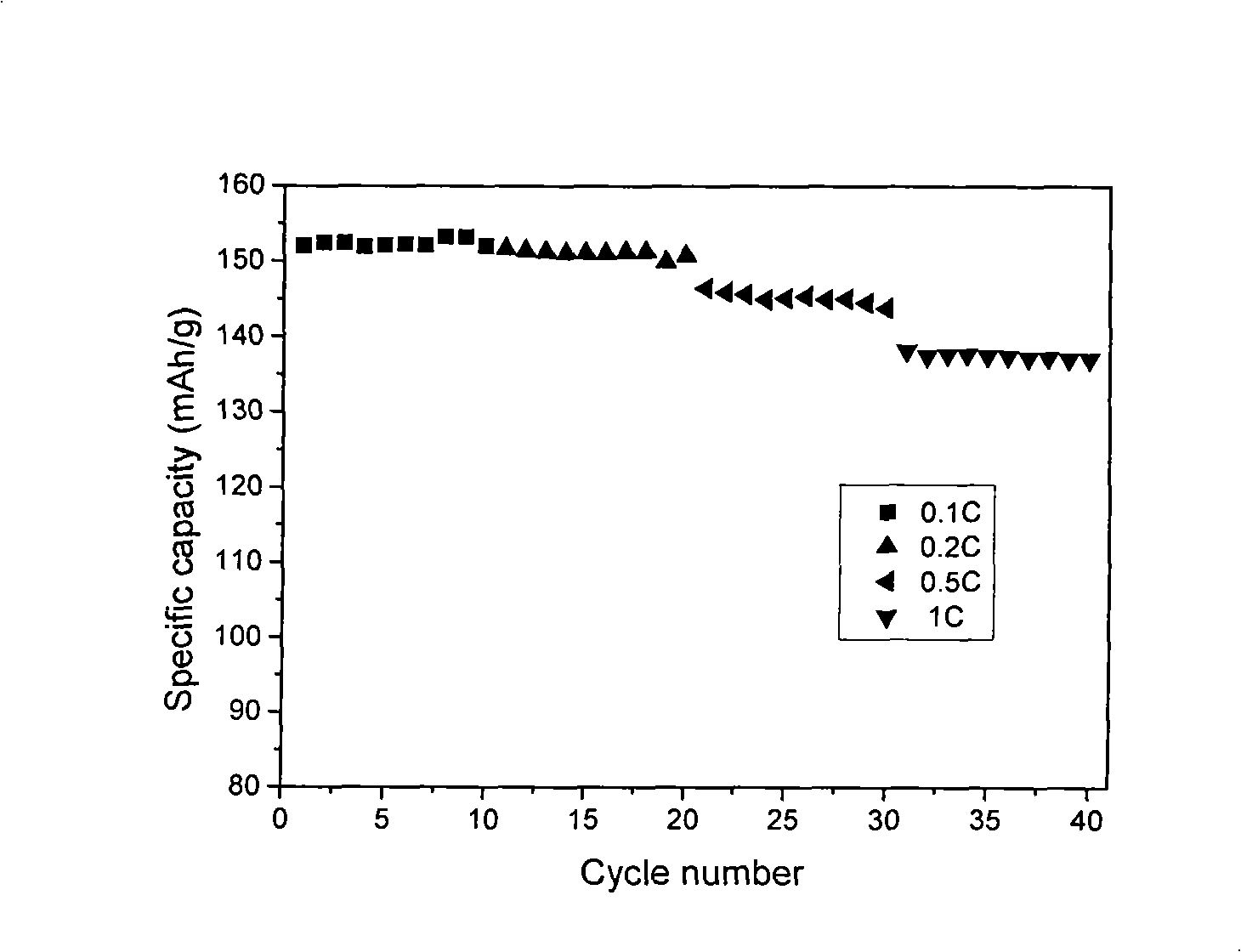

[0024] Lithium iron phosphate (LiFePO 4 / C) Material powder, acetylene black, and water-based adhesive are mix...

Embodiment 2

[0026] Take by weighing 3.7318g (0.05mol) lithium carbonate, 8.4053g (0.05mol) ferric oxide, 9.2954g (0.08mol) ammonium dihydrogen phosphate, 1.37ml concentration is 85% phosphoric acid, 2.96g (0.018mol) lactose and 0.50 g citric acid; then mix well, grind for 20 minutes, put it in an oven and dry it at 100°C; take it out and mill it for 15 minutes, put the mixture in a tube furnace, blow it with inert gas for 3-5 minutes, and seal it; / min raised to 700°C, kept at constant temperature for 6 hours, then cooled naturally to room temperature and taken out to produce lithium iron phosphate (LiFePO 4 / C) The material was 14.3 grams.

[0027] Lithium iron phosphate (LiFePO 4 / C) Material powder, acetylene black, and water-based adhesive are mixed evenly in a mass ratio of 85:10:5, and then coated on a 0.02mm aluminum foil, and then fully dried to obtain a positive electrode sheet, and then filled with argon The experimental battery was installed in the glove box; the charge and d...

Embodiment 3

[0030]Take by weighing 3.7318g (0.05mol) lithium carbonate, 8.4053g (0.05mol) ferric oxide, 6.83ml concentration is 85% phosphoric acid, 2.00g (0.011mol) glucose, put into mortar and grind after 15 minutes and mix homogeneously, Dry it in an oven at 110°C, take it out and mill it for 10 minutes, put the mixture in a tube furnace, blow it with inert gas for 3-5 minutes, and seal it. Rise to 650°C at 15°C / min, keep the temperature for 6 hours, cool naturally to room temperature and take it out to prepare LiFePO 4 The / C material is 14.2 grams.

[0031] Carry out charge and discharge cycle performance test with example 1: with constant current 0.3mA / cm 2 The charge and discharge test was carried out, the charge and discharge voltage was 2.5V-4.2V, and the reversible specific capacity measured at room temperature was 141.0mAh / g.

[0032] The raw material in the early stage of this embodiment adopts solid-liquid combination, and the phosphoric acid in the liquid phase is used as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com