Ti-based high temperature alloy with high toughness in bi-state structure and preparation method and application thereof

A high-temperature alloy and two-state structure technology, applied in the field of high-strength and tough titanium-based superalloy and its preparation, can solve the problems of high cost, complicated preparation process, large alloy grain size, etc., and achieve convenient operation, simple processing process, and high-quality products. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

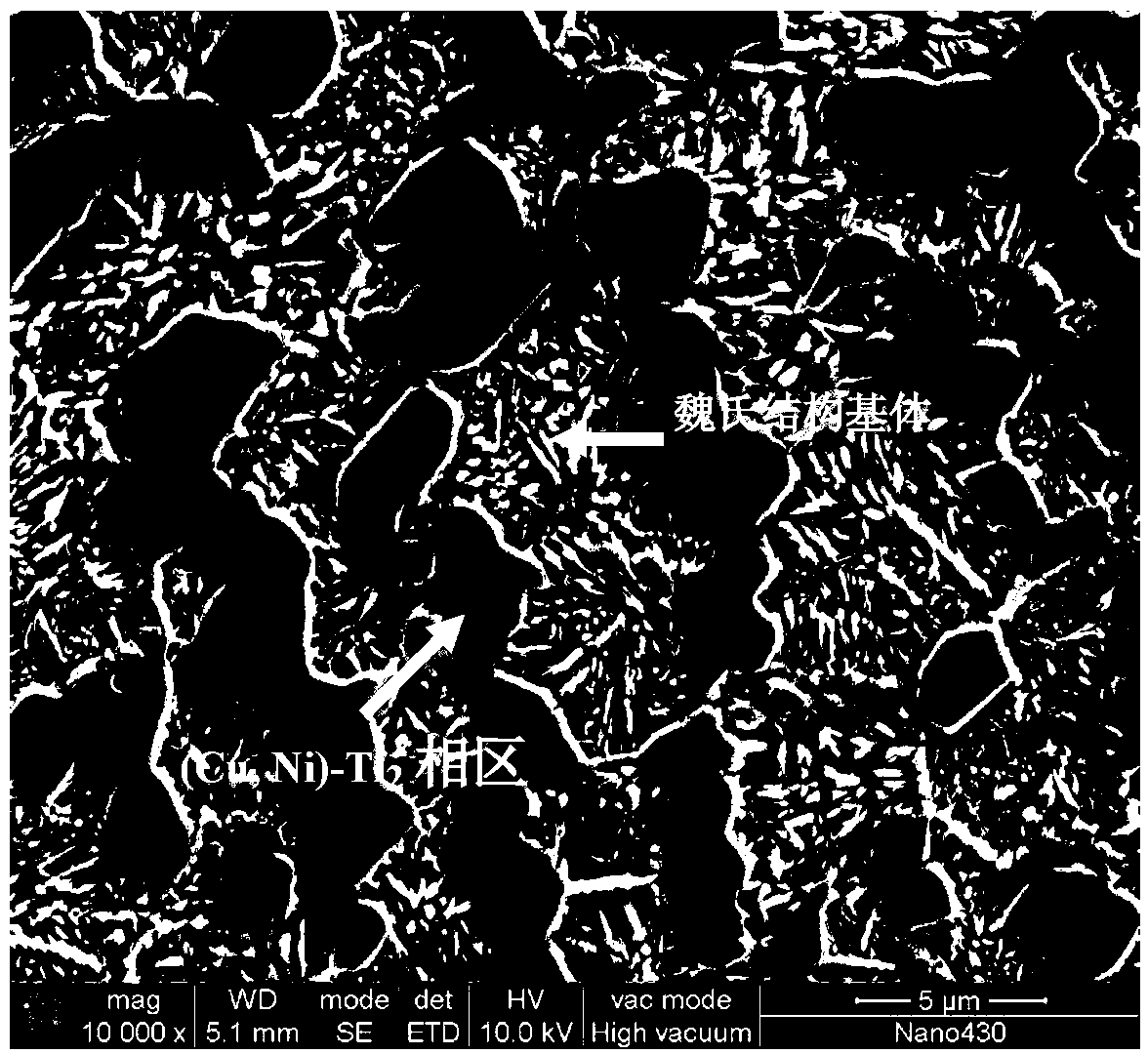

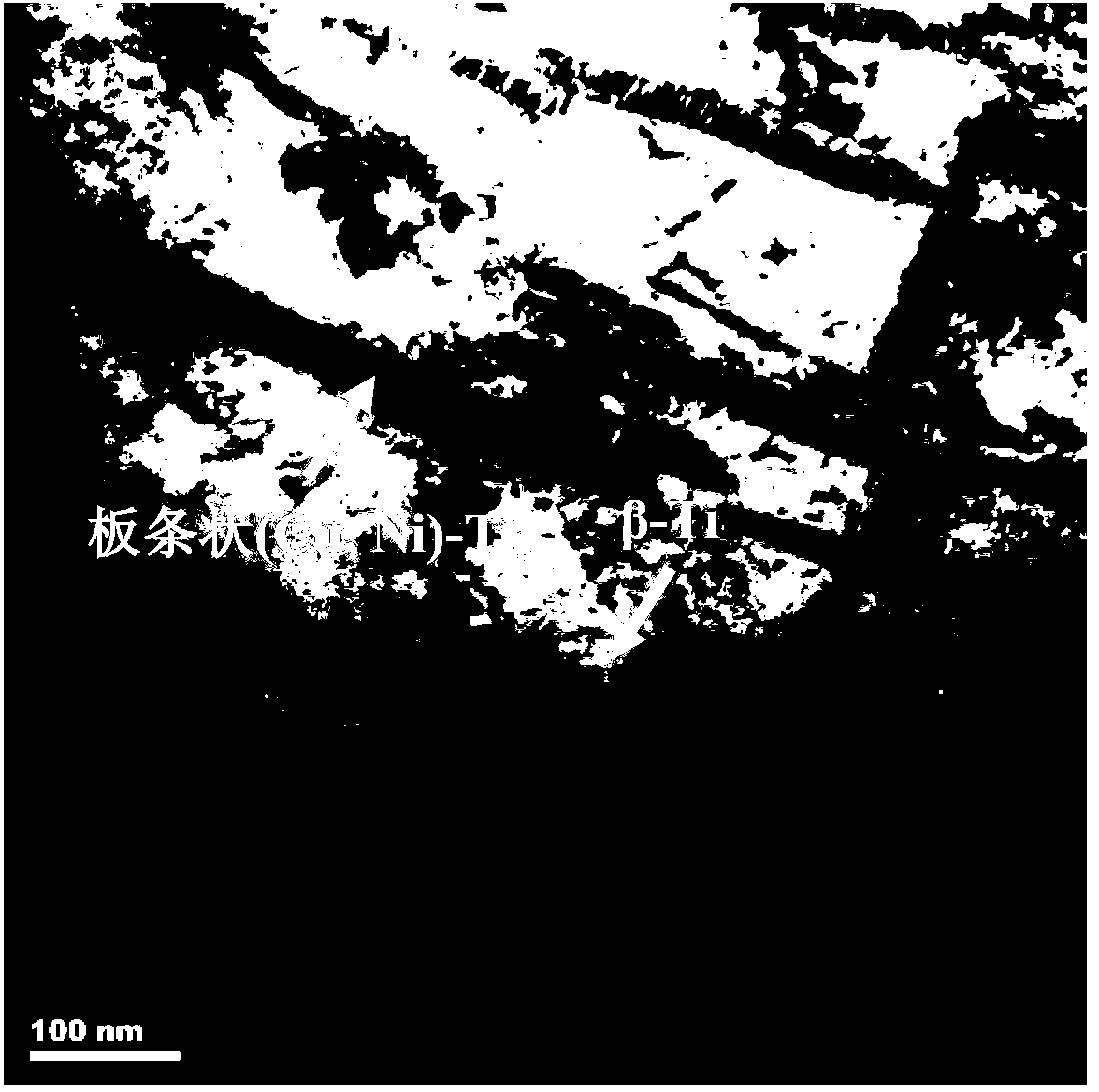

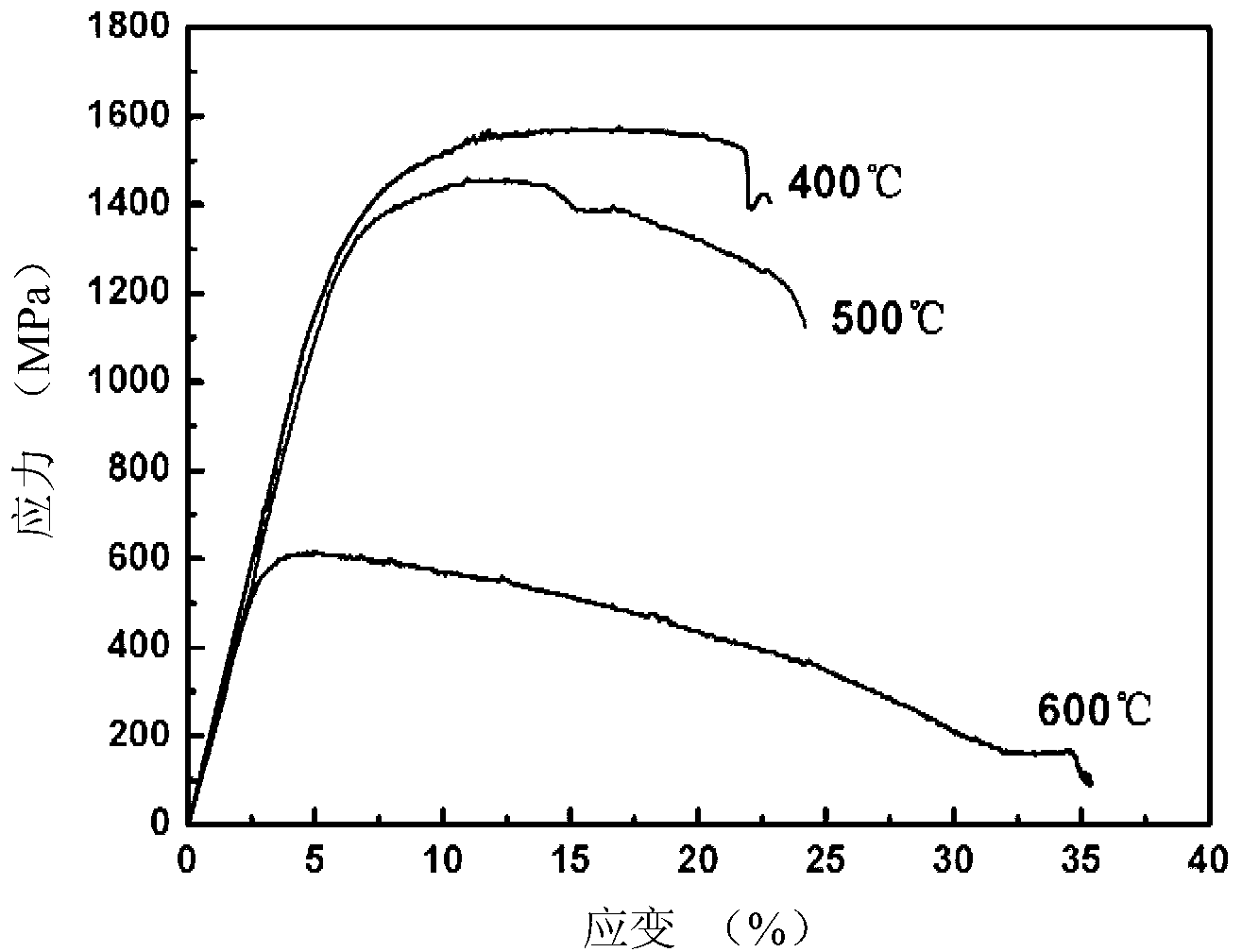

[0039] Example 1: Preparation of a high-strength and tough titanium-based superalloy with a two-state structure

[0040] (1) Preparation of alloy powder by high energy ball milling

[0041] Mix the components evenly and place them in a planetary ball mill (QM-2SP20) for high-energy ball milling to obtain alloy powder.

[0042] Among them, the distribution ratio of each component is: Ti66at.%, Nb13at.%, Cu8at.%, Ni6.8at.%, Al6.2at.%; all components are elemental powder, the particle size is about 75μm.

[0043] Ball mill: The ball milling media such as tank body and ball material are all stainless steel, the ball diameters are 15, 10 and 6mm respectively, and their weight ratio is 1:3:1.

[0044] The process parameters of high-energy ball milling are as follows: the ball mill tank is filled with high-purity argon (99.999%, 0.5MPa) for protection, the ball-to-material ratio is 8:1, and the rotation speed is 2s -1 , the milling time is 1h.

[0045] (2) Pulse current sintered a...

Embodiment 2

[0056] Example 2: Preparation of a high-strength and tough titanium-based superalloy with a two-state structure

[0057] (1) Preparation of alloy powder by high energy ball milling

[0058] Mix the components evenly and place them in a planetary ball mill (QM-2SP20) for high-energy ball milling to obtain alloy powder.

[0059] Among them, the distribution ratio of each component is: Ti68at.%, Nb8at.%, Cu10at.%, Ni6at.%, Al8at.%; all components are elemental powder, and the particle size is about 100μm.

[0060] Ball mill: The ball milling media such as tank body and ball material are all stainless steel, the ball diameters are 15, 10 and 6mm respectively, and their weight ratio is 1:3:1.

[0061] The high-energy ball mill process parameters are as follows: the ball mill tank is filled with high-purity argon (99.999%, 0.5MPa) for protection, the ball-to-material ratio is 10:1, and the rotation speed is 3.8s -1 , The ball milling time is 20h.

[0062] (2) Pulse current sinter...

Embodiment 3

[0072] Example 3: Preparation of a high-strength and tough titanium-based superalloy with a two-state structure

[0073] (1) Preparation of alloy powder by high energy ball milling

[0074] Mix the components evenly and place them in a planetary ball mill (QM-2SP20) for high-energy ball milling to obtain alloy powder.

[0075] Among them, the distribution ratio of each component is: Ti64at.%, Nb18at.%, Cu6at.%, Ni5at.%, Al7at.%; all components are elemental powder, and the particle size is about 150μm.

[0076] Ball mill: The ball milling media such as tank body and ball material are all stainless steel, the ball diameters are 15, 10 and 6mm respectively, and their weight ratio is 1:3:1.

[0077] The high-energy ball milling process parameters are as follows: the ball milling tank is filled with high-purity argon (99.999%, 0.5MPa) for protection, the ball-to-material ratio is 12:1, and the rotation speed is 5s -1 , The ball milling time is 30h.

[0078] (2) Pulse current si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com