High-color-stability PVC (polyvinyl chloride) resin

A PVC resin and stability technology, applied in the field of PVC resin with high color stability, can solve the problems of dispersion effect, product quality, pigment loss, etc., to improve compatibility, improve mechanical stability, and improve stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

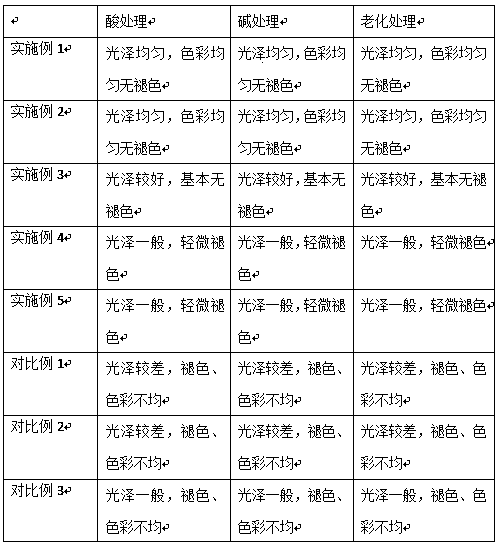

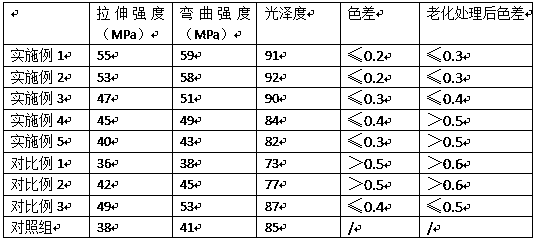

Examples

Embodiment 1

[0039] A PVC resin with high color stability, adding 5% color masterbatch of matrix resin weight to PVC matrix resin,

[0040] The color masterbatch is made of the following raw materials by weight: 13 parts of pigment, 1.1 parts of dispersant, 32 parts of PVC resin, 0.65 parts of antioxidant, and 18 parts of filler;

[0041] The filler is prepared using the following method:

[0042] (1) Dry the diatomaceous earth;

[0043] (2) Soak the montmorillonite in a nitric acid solution with a mass fraction of 15% for 35 minutes, use ultrasonic vibration treatment during the soaking process, and then dry it;

[0044] (3) Take 10 parts of polyethylene glycol, 0.3 parts of expanded graphite, 1.5 parts of glass fiber, and 15 parts of water by weight, and stir at 40°C for 1.2 hours to obtain a mixed solution;

[0045] (4) Mix the diatomite prepared in step (1), the montmorillonite prepared in step (2), and the mixed solution obtained in step (3) in a ratio of 4:1.2:3 by weight, at 550r / ...

Embodiment 2

[0063] Compared with Example 1, the color masterbatch is made of the following raw materials by weight: 15 parts of pigment, 1.3 parts of dispersant, 35 parts of PVC resin, 0.7 parts of antioxidant, 20 parts of filler, and other processing methods are the same as in Example 1 .

Embodiment 3

[0065] The glass fibers are not modified, and the others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com