PVC plastic floor and preparation method thereof

A stone-plastic floor and substrate technology, used in the field of floor manufacturing, can solve the problems of dimensional deviation, low strength of stone-plastic floor, gaps of different sizes, air bubbles or air chambers, etc., to improve strength and tensile force, product installation Good effect and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings, but the embodiments of the present invention described below are only examples and do not constitute any limitation to the present invention.

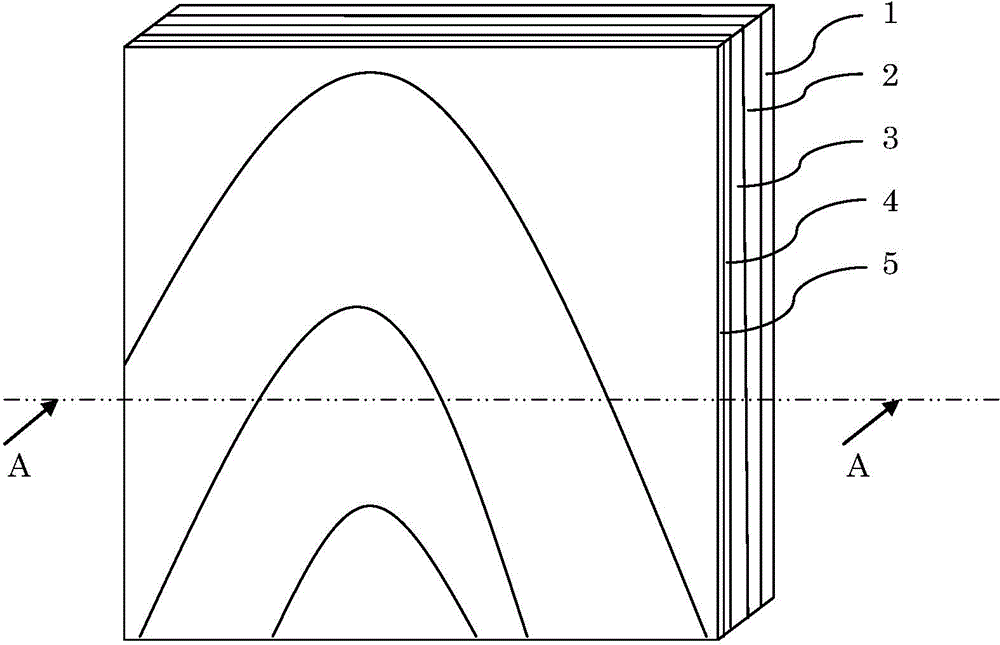

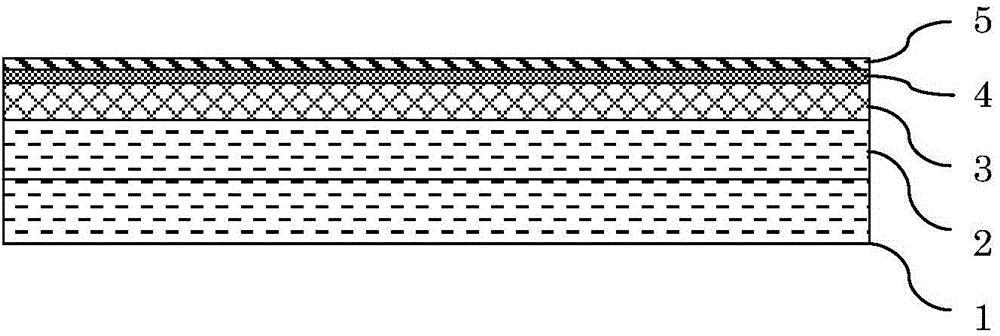

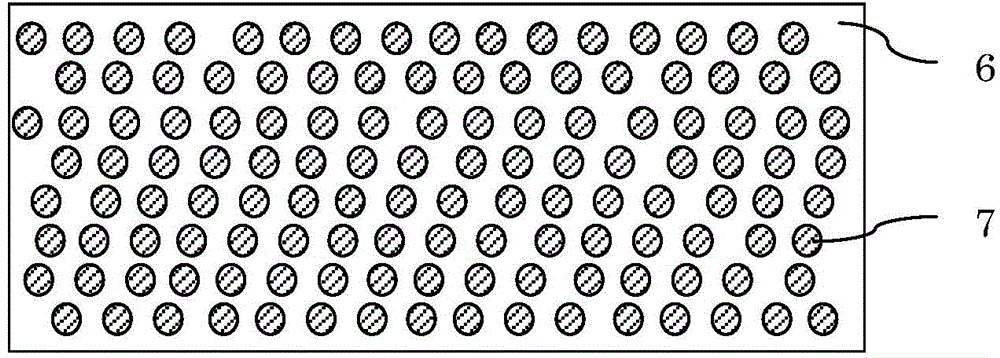

[0022] This embodiment provides a stone-plastic floor, such as figure 1 and figure 2 As shown, it includes a substrate layer 1, an intermediate layer 2, a decorative layer 3, a wear-resistant layer 4 and a paint layer 5 joined in sequence, at least one of the substrate layer 1 and the intermediate layer 2 comprises a PVC matrix and is dispersed in the Filler particles in the PVC matrix, wherein the filler particles are composed of SiO 2 、Al 2 o 3 , CaCO 3 , The composition of NaCl. The mass percentage of the filler particles contained in at least one layer of the substrate layer 1 and the middle layer 2 is 45% to 55%, for exa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com