High-impact-resistance PVC tube

A PVC pipe, high impact resistance technology, applied in the field of PVC pipe, can solve the problems of decreased strength and stiffness, reduced toughness of PVC material, volatilization under heat, etc., to achieve the effect of improving high temperature stability, tensile strength and impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

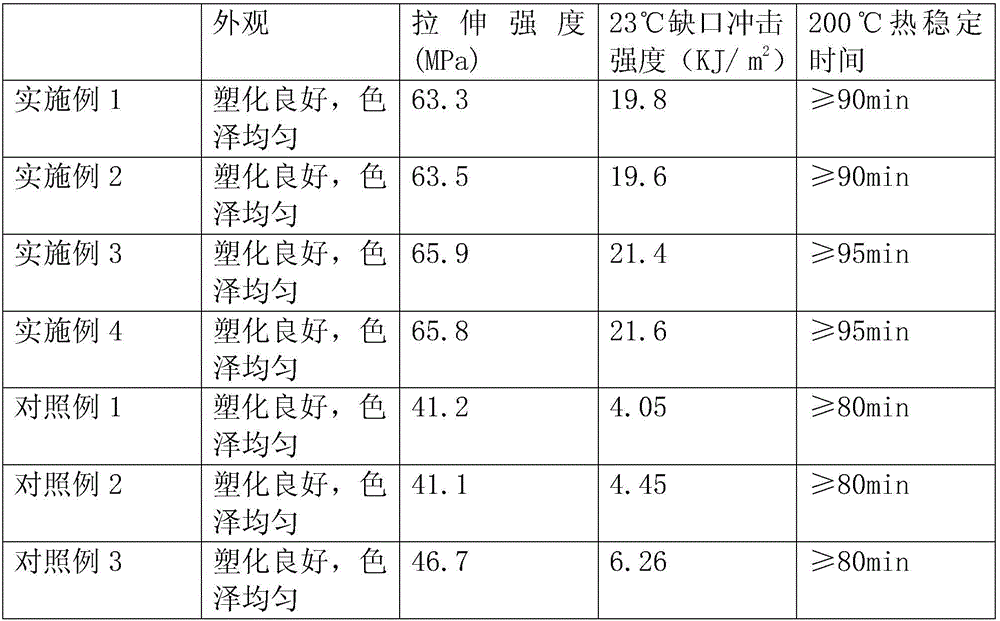

Examples

Embodiment 1

[0020] Formula: 100 parts of PVC resin with a polymerization degree of 800, 5 parts of titanium dioxide, 0.1 part of CPE, and 0.1 part of ACM.

[0021] 1) Premix PVC resin, titanium dioxide, CPE, and ACM in a high-speed mixer, and cool to obtain a premix;

[0022] 2) Melt and mix the premixed material with a torque rheometer at 160° C. and a rotational speed of 40 rpm for 2 to 10 minutes to obtain a composite material.

[0023] 3) Send the composite material into the twin-screw extruder, the screw speed is 100rpm, the barrel temperature is set: the feeding section is 160°C, the plasticizing section is 170°C, the head temperature is 180°C, and the output is high impact resistance PVC pipe.

Embodiment 2

[0025] Formula: 100 parts of PVC resin with a polymerization degree of 2000, 10 parts of titanium dioxide, 0.3 parts of CPE, and 0.3 parts of ACM.

[0026] 1) Premix PVC resin, titanium dioxide, CPE, and ACM in a high-speed mixer, and cool to obtain a premix;

[0027] 2) Melt and mix the premixed material with a torque rheometer at 180° C. and a rotational speed of 80 rpm for 10 minutes to obtain a composite material.

[0028] 3) Send the composite material into the twin-screw extruder, the screw speed is 120rpm, the barrel temperature is set: the feeding section is 175°C, the plasticizing section is 180°C, the head temperature is 195°C, and the output is high impact resistance PVC pipe.

Embodiment 3

[0030] Formula: 100 parts of PVC resin with a polymerization degree of 1500, 6 parts of titanium dioxide, 0.15 parts of CPE, and 0.15 parts of ACM.

[0031] 1) Premix PVC resin, titanium dioxide, CPE, ACM, and rare earth stearate in a high-speed mixer, and cool to obtain a premix;

[0032] 2) Melt and mix the premixed material with a torque rheometer at 170° C. and a rotational speed of 60 rpm for 8 minutes to obtain a composite material.

[0033] 3) Send the composite material into the twin-screw extruder, the screw speed is 110rpm, the barrel temperature is set: the feeding section is 170°C, the plasticizing section is 175°C, the head temperature is 190°C, and the output is high impact resistance PVC pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com