Surface treatment method for novel crystal whiskers applied to PVC

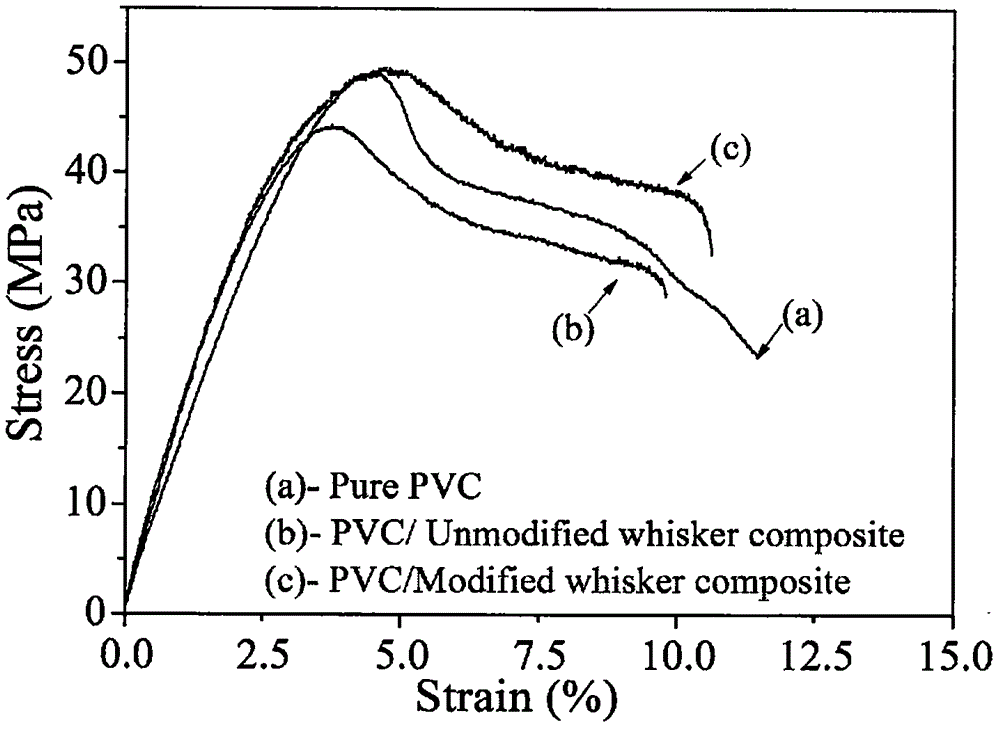

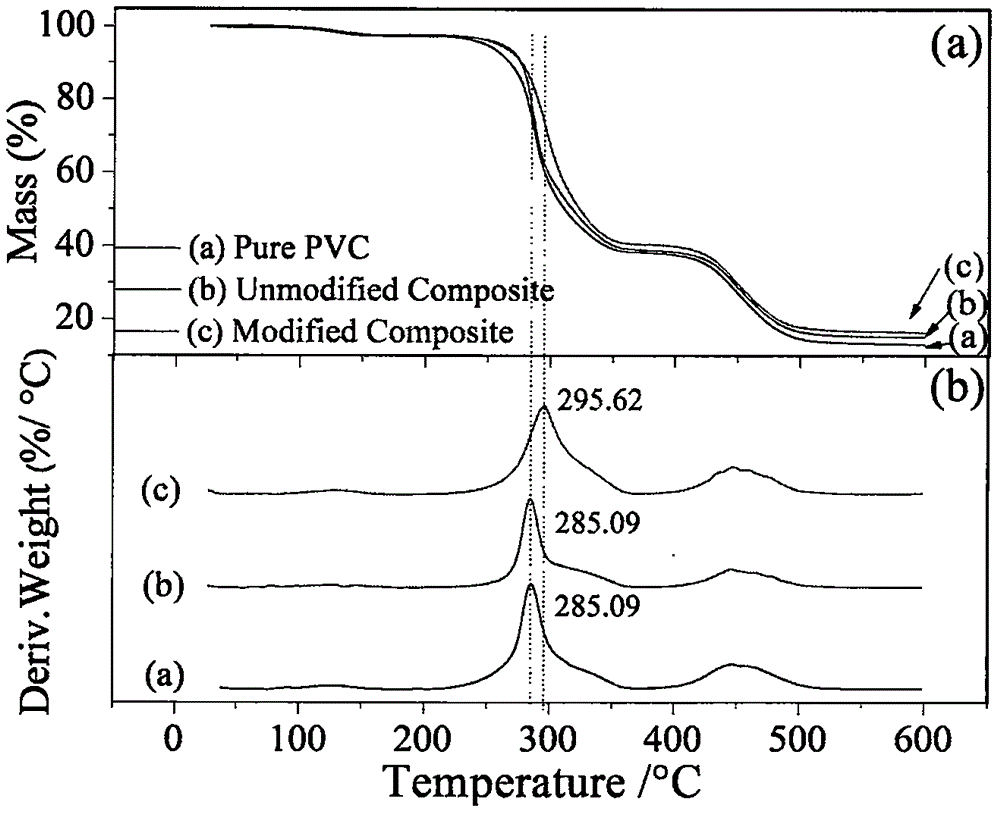

A surface treatment and whisker technology, applied in the field of new whisker surface treatment, can solve the problem of rarely using whiskers, and achieve the effect of improving mechanical properties, thermal stability and high practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A novel whisker surface treatment method applied in PVC, comprising steps as follows:

[0038] (1) Firstly, the whiskers are dried in an oven to remove possible physical adsorption and weak chemical adsorption. According to the volume ratio of 1:20, γ-methacryloxypropyltrimethoxysilane was dissolved in ethanol solution (ethanol: water = 1:10) for hydrolysis, and finally the whiskers were dissolved in a mass ratio of 1:50. Disperse in an ethanol solution containing γ-methacryloxypropyltrimethoxysilane, heat the reaction system to 80°C, stir and reflux for 12 hours, the stirring speed of stirring and reflux is 250r / min, and finally wash the whiskers , to prepare calcium carbonate whiskers with double bonds on the surface.

[0039] (2) the calcium carbonate whisker that has double bond on the surface obtained in step (1), with potassium persulfate (accounting for 1.5wt.% of whisker quality), sodium dodecylsulfonate (accounting for reaction solution quality 0.15wt.%), met...

Embodiment 2

[0043] A novel whisker surface treatment method applied in PVC, comprising steps as follows:

[0044](1) Firstly, the whiskers are dried in an oven to remove possible physical adsorption and weak chemical adsorption. According to the volume ratio of 1:20, γ-methacryloxypropyltrimethoxysilane was dissolved in ethanol solution (ethanol: water = 1:10) for hydrolysis, and finally the whiskers were dissolved in a mass ratio of 1:50. Disperse in an ethanol solution containing γ-methacryloxypropyltrimethoxysilane, heat the reaction system to 80°C, stir and reflux for 12 hours, the stirring speed of stirring and reflux is 250r / min, and finally wash the whiskers , to prepare calcium carbonate whiskers with double bonds on the surface.

[0045] (2) the calcium carbonate whisker with double bond on the surface obtained in step (1), with potassium persulfate (accounting for 2wt.% of whisker quality), sodium dodecylsulfonate (accounting for 2wt.% of reaction solution quality) 0.3wt.%), m...

Embodiment 3

[0049] A novel whisker surface treatment method applied in PVC, comprising steps as follows:

[0050] (1) Firstly, the whiskers are dried in an oven to remove possible physical adsorption and weak chemical adsorption. According to the volume ratio of 1:20, γ-methacryloxypropyltrimethoxysilane was dissolved in ethanol solution (ethanol: water = 1:10) for hydrolysis, and finally the whiskers were dissolved according to the mass ratio of 1:50. Disperse in an ethanol solution containing γ-methacryloxypropyltrimethoxysilane, heat the reaction system to 80°C, stir and reflux for 12 hours, the stirring speed of stirring and reflux is 250r / min, and finally wash the whiskers , to prepare calcium carbonate whiskers with double bonds on the surface.

[0051] (2) the calcium carbonate whisker that the surface that obtains in step (1) has double bond, and potassium persulfate (accounting for 4wt.% of whisker quality), sodium dodecylsulfonate (accounting for 4wt.% of reaction solution qual...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com