Polyanionic metal salt, preparation method thereof and heat stabilizer

A polyanion and heat stabilizer technology, applied in the field of polyvinyl chloride heat stabilizers, can solve the problem that the main stabilizer and auxiliary heat stabilizer are difficult to disperse in the same microscopic area, and achieve good heat stability effect and high degree of coordination Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

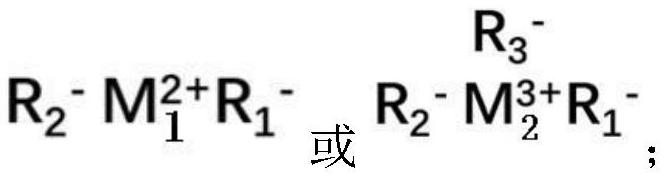

Image

Examples

Embodiment 1

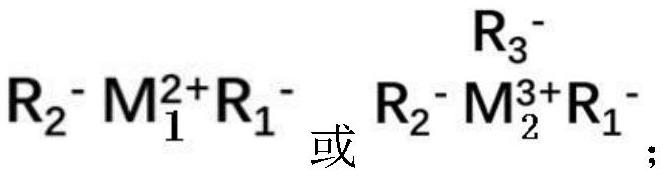

[0045] (1) Preparation of norfloxacin zinc stearate (A):

[0046] Dissolve 1 mol of zinc acetate in 100 mL of 50% ethanol aqueous solution, then add 1 mol of norfloxacin and stearic acid to the above solution, adjust the pH value of the solution to 4.0, react at 80°C for 5 hours, filter the precipitate and wash with ethanol After washing with the aqueous solution, place it in an oven at 60°C and dry to constant weight to obtain norfloxacin zinc stearate (A);

[0047](2) carry out batching according to following formula: 2phr norfloxacin zinc stearate (A), 6phr epoxy soybean oil, 30phr dibutyl terephthalate, 0.5phr antioxidant 1010, 0.5phr antioxidant 168, 0.5phr PE wax, 0.5phr stearic acid, 5phr hydrotalcite, heat stabilizer;

[0048] (3) Add the heat stabilizer to the 100phr PVC matrix and mix evenly. After pre-plasticizing in an oven at 60°C for 10 minutes, place it on a double-roll mill at 180°C. Mix at a high speed for 3 minutes to obtain a PVC sample; the obtained PVC s...

Embodiment 2

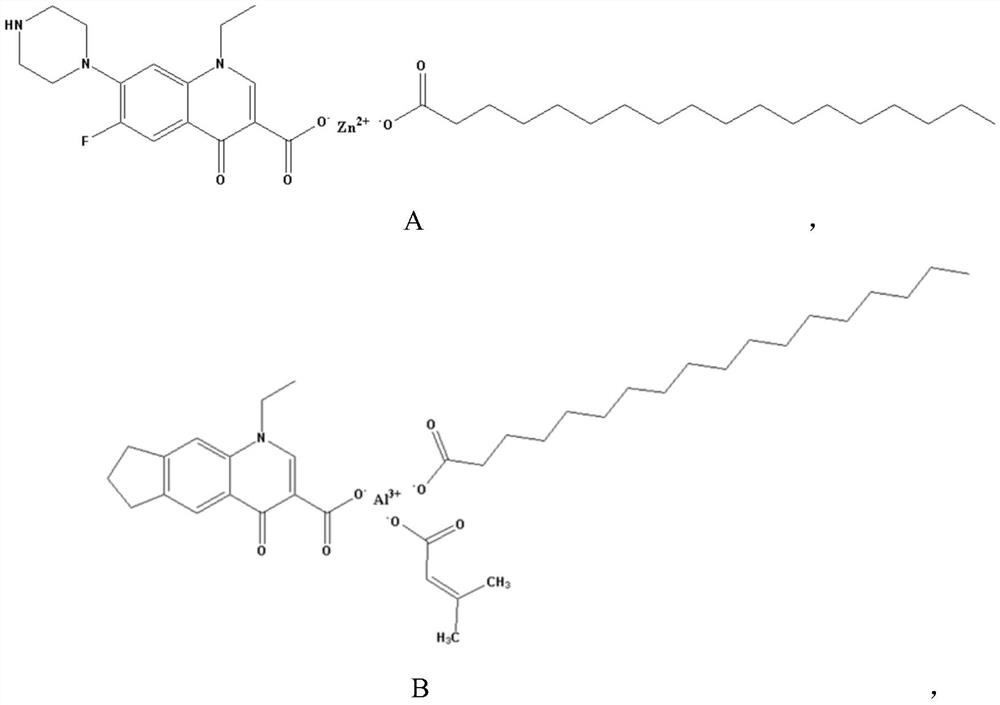

[0050] (1) Preparation of oxaquilic acid dimethacrylate aluminum stearate (B):

[0051] Dissolve 1 mol of aluminum isopropoxide in 100 mL of chloroform, then add 1 mol each of oxacrylic acid, dimethacrylic acid and stearic acid to the above solution, adjust the pH value to 8.0, and react at 50°C for 4 hours. After the precipitate was filtered and washed with chloroform, it was dried in a drying oven at 70°C to constant weight to obtain aluminum oxquilic acid dimethacrylate stearate (B);

[0052] (2) Ingredients are prepared according to the following formula: 3phr oxaquilic acid aluminum stearate dimethacrylate (B), 3phr epoxy soybean oil, 2phr β-diketone, 2phr stearic acid, 0.5phr PE wax, 10phr phthalate Dibutyl formate, 1phr antioxidant 1010, 1phr antioxidant 168, 3phr calcium carbonate, heat stabilizer;

[0053] (3) Add the heat stabilizer to the 100phr PVC matrix and mix evenly. After pre-plasticizing in an oven at 60°C for 10 minutes, place it on a double-roll mill at 18...

Embodiment 3

[0055] (1) Preparation of magnesium orotate dimethacrylate (C):

[0056] Dissolve 1 mol of magnesium ethoxide in 100 mL of 50% ethanol aqueous solution, then add 1 mol of orotic acid and dimethacrylic acid to the above solution, adjust the pH value to 5.0, react at 40°C for 3 hours, filter the precipitate and use After washing with an aqueous ethanol solution, dry to constant weight in a drying oven at 50°C to obtain magnesium orotic acid dimethacrylate (C);

[0057] (2) Dosing according to the following formula: 3phr magnesium orotate dimethacrylate, 2phr pentaerythritol, 4phr beta-diketone, 2phr stearic acid, 2phr PE wax, 15phr plasticizer, 2phr antioxidant 1010, 2phr antioxidant (3) Add the heat stabilizer to the 100phr PVC matrix and mix evenly, pre-plasticize in an oven at 60°C for 10min, place it on a double-roll mill at 180°C, and heat it at 11r / min and 9r / min front and rear roll speeds for 3min to obtain a PVC sample; the resulting PVC sample was further compressed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com