Patents

Literature

72 results about "Cation binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

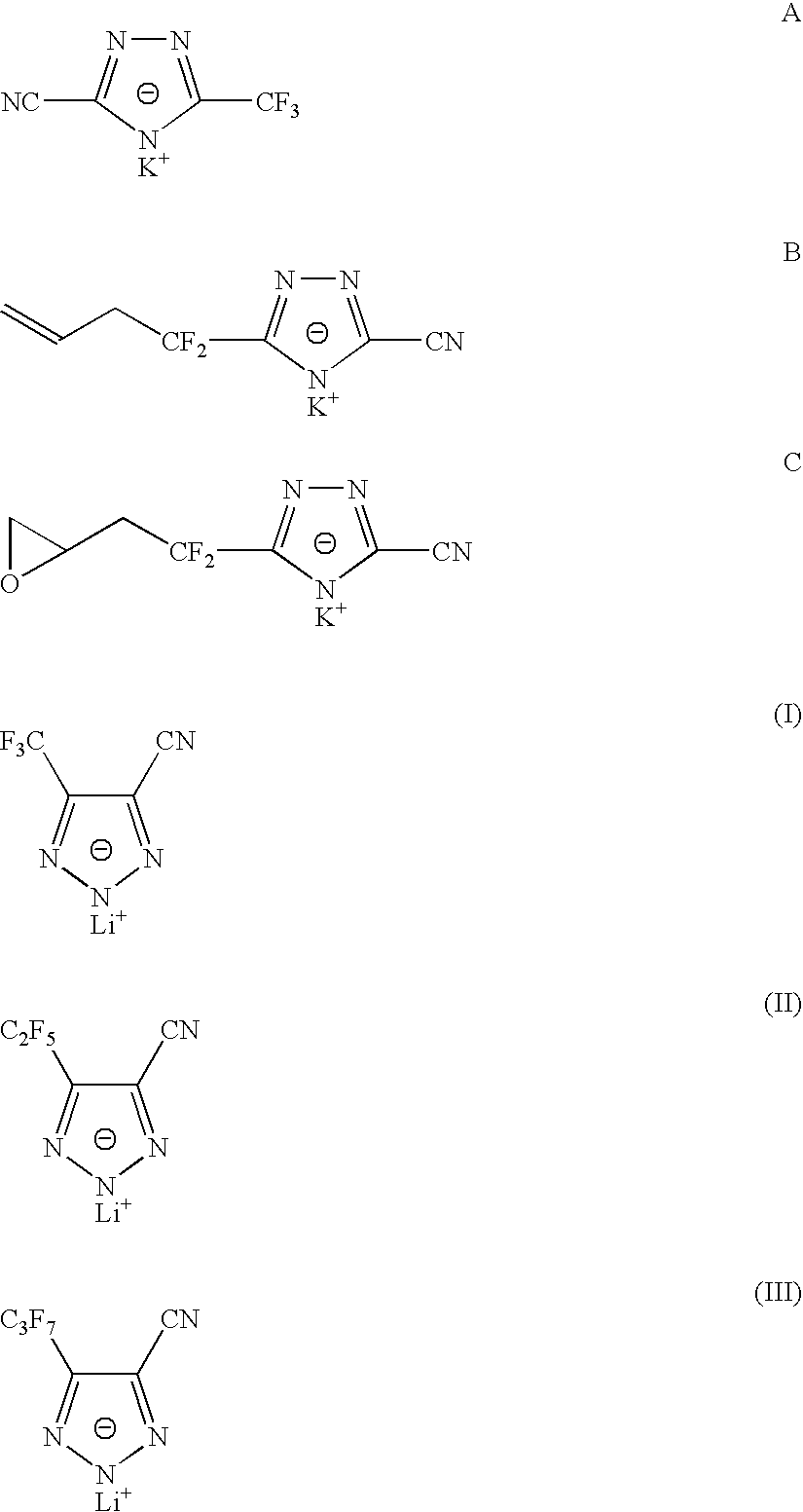

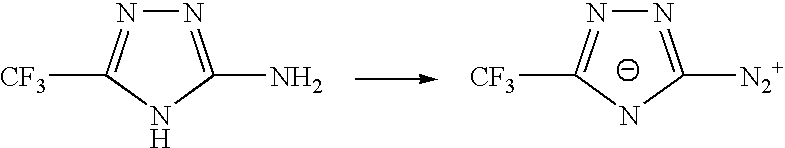

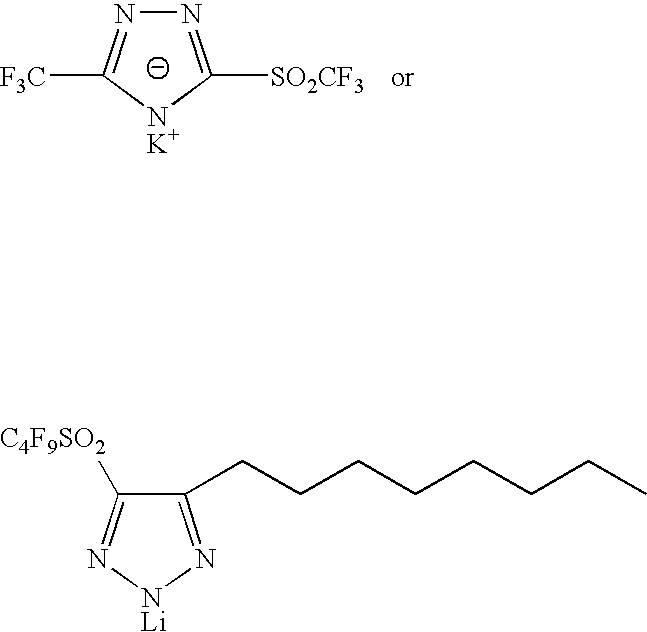

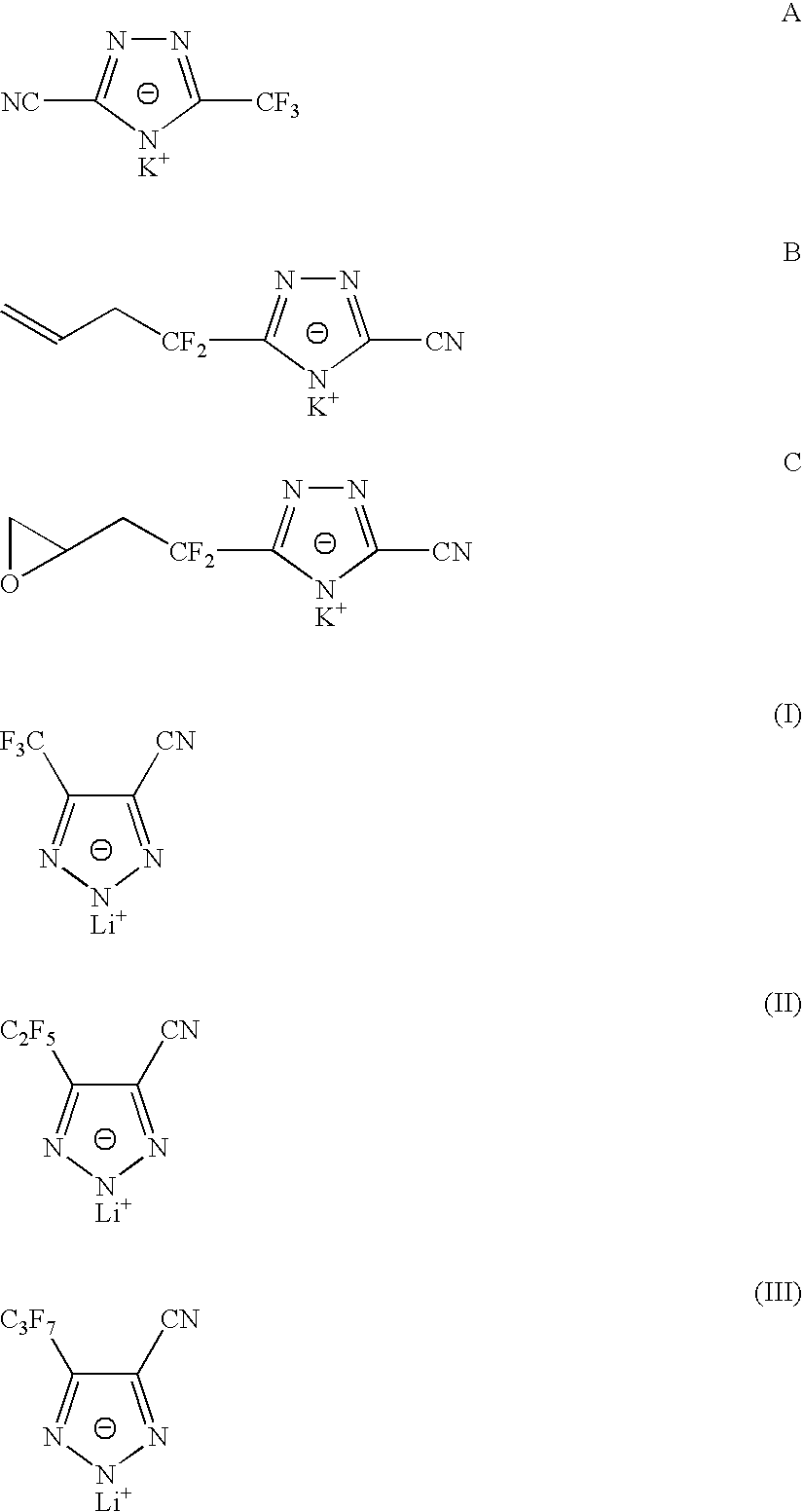

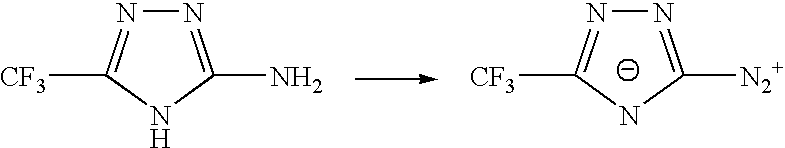

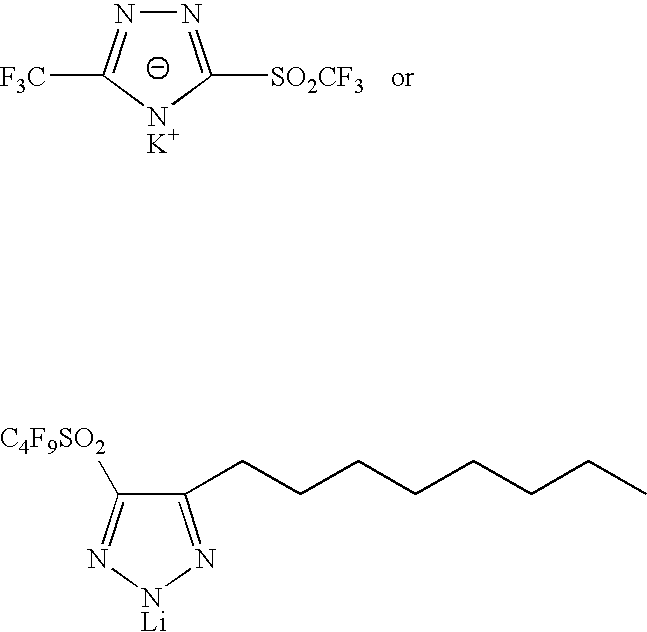

Sulphonyl-1,2,4-triazole salts

InactiveUS7919629B2Easy to prepareImprove conductivityOrganic chemistryChemical reactionSupercapacitor

The invention relates to triazole salts, to their preparation and to applications thereof. The salts have at least one anionic triazolium group which carries at least one chlorosulphonyl, fluorosulphonyl or alkoxyfluorosulphonyl group, each of the anionic groups being combined with a proton or a cation that has a valency of less than or equal to 4. The salts are useful as synthesis reagents, as chemical-reaction or polymerization catalysts, and as ion-conducting materials for electrochemical generators, supercapacitors and electrochromic devices.

Owner:PHOSTECH LITHIUM +1

Sulphonyl-1,2,4-triazole salts

InactiveUS20090292105A1Readily dispersibleHigh viscosityOrganic chemistryChemical reactionSupercapacitor

The invention relates to triazole salts, to their preparation and to applications thereof. The salts have at least one anionic triazolium group which carries at least one chlorosulphonyl, fluorosulphonyl or alkoxyfluorosulphonyl group, each of the anionic groups being combined with a proton or a cation that has a valency of less than or equal to 4. The salts are useful as synthesis reagents, as chemical-reaction or polymerization catalysts, and as ion-conducting materials for electrochemical generators, supercapacitors and electrochromic devices.

Owner:PHOSTECH LITHIUM +1

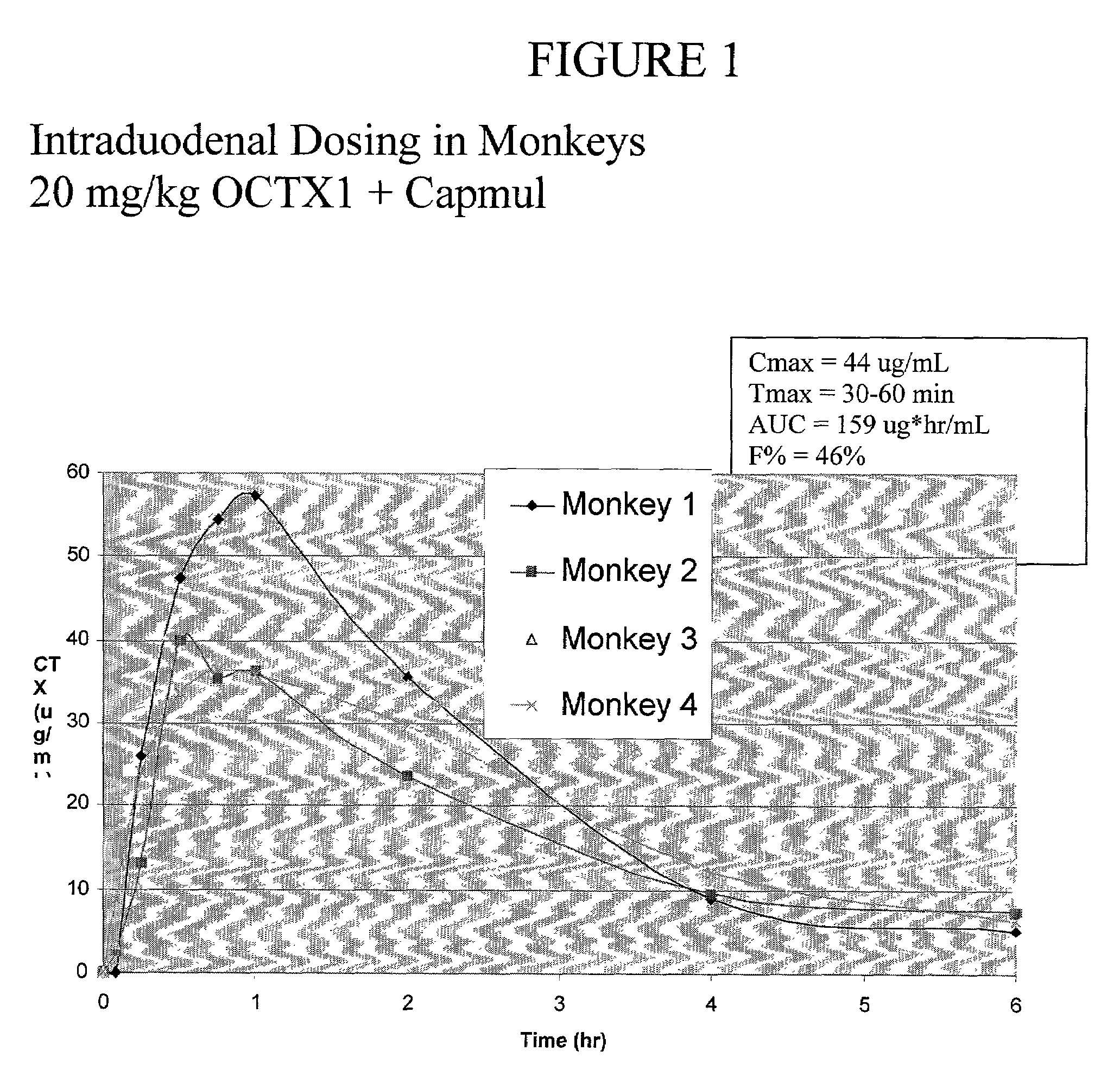

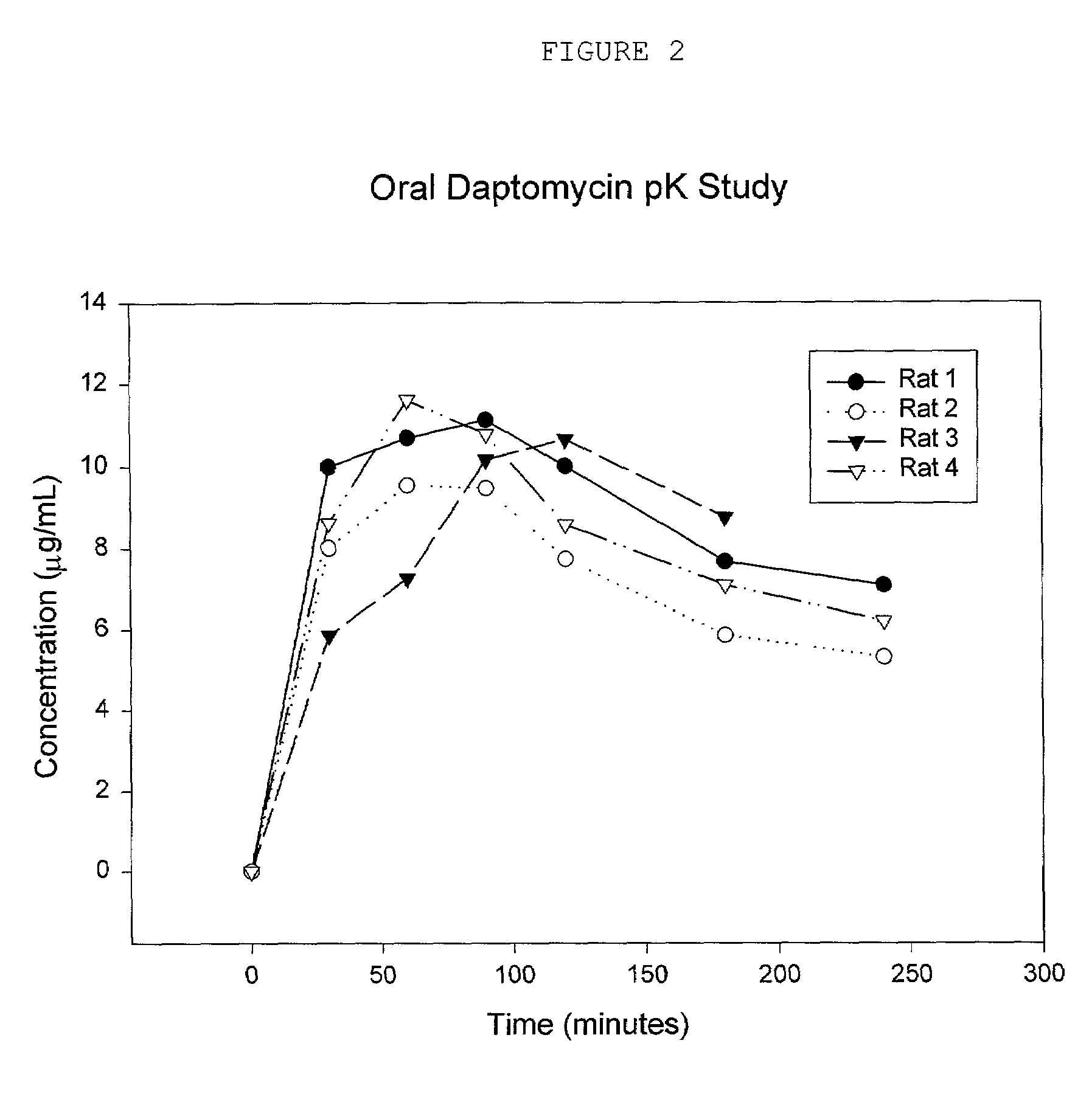

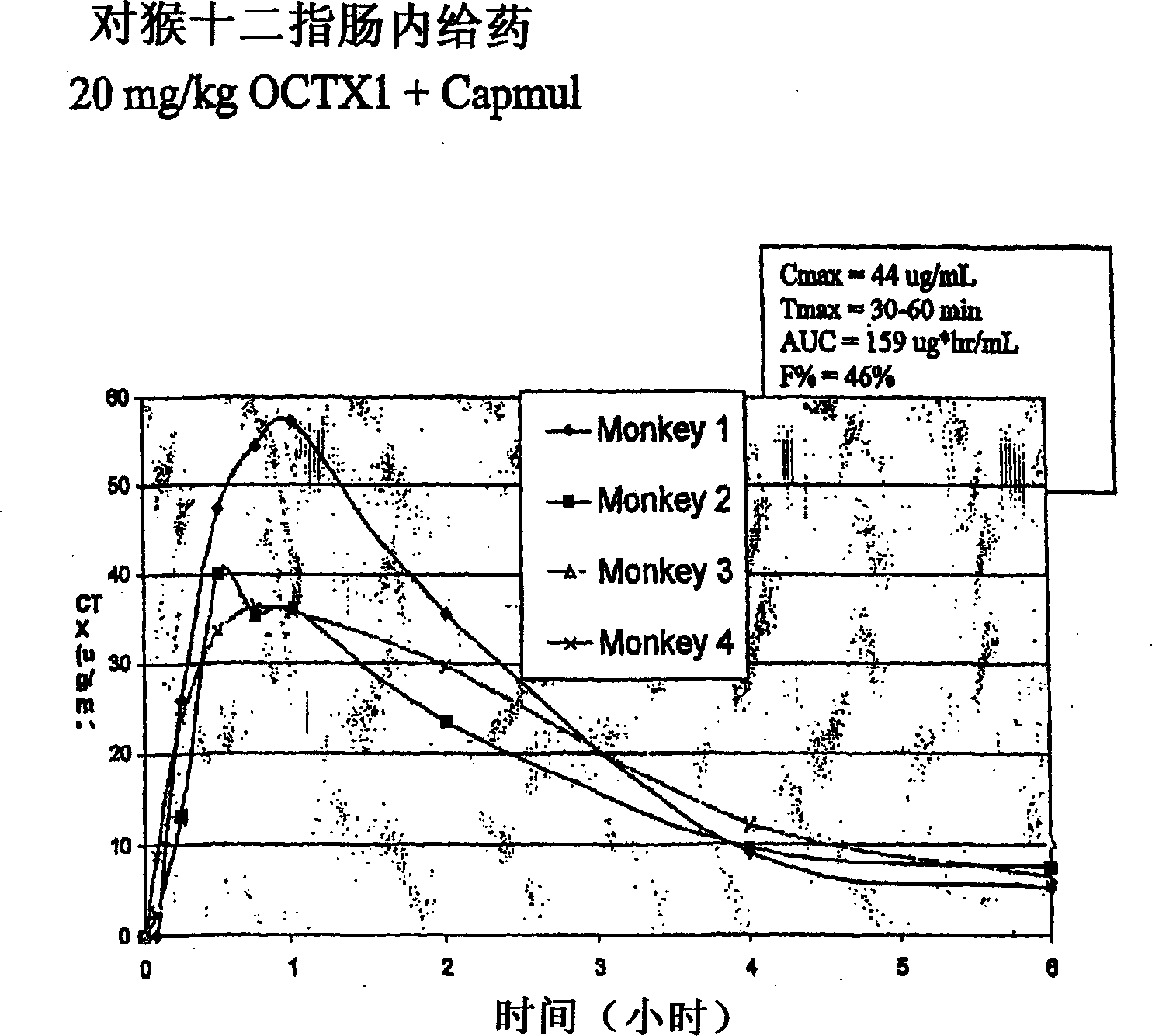

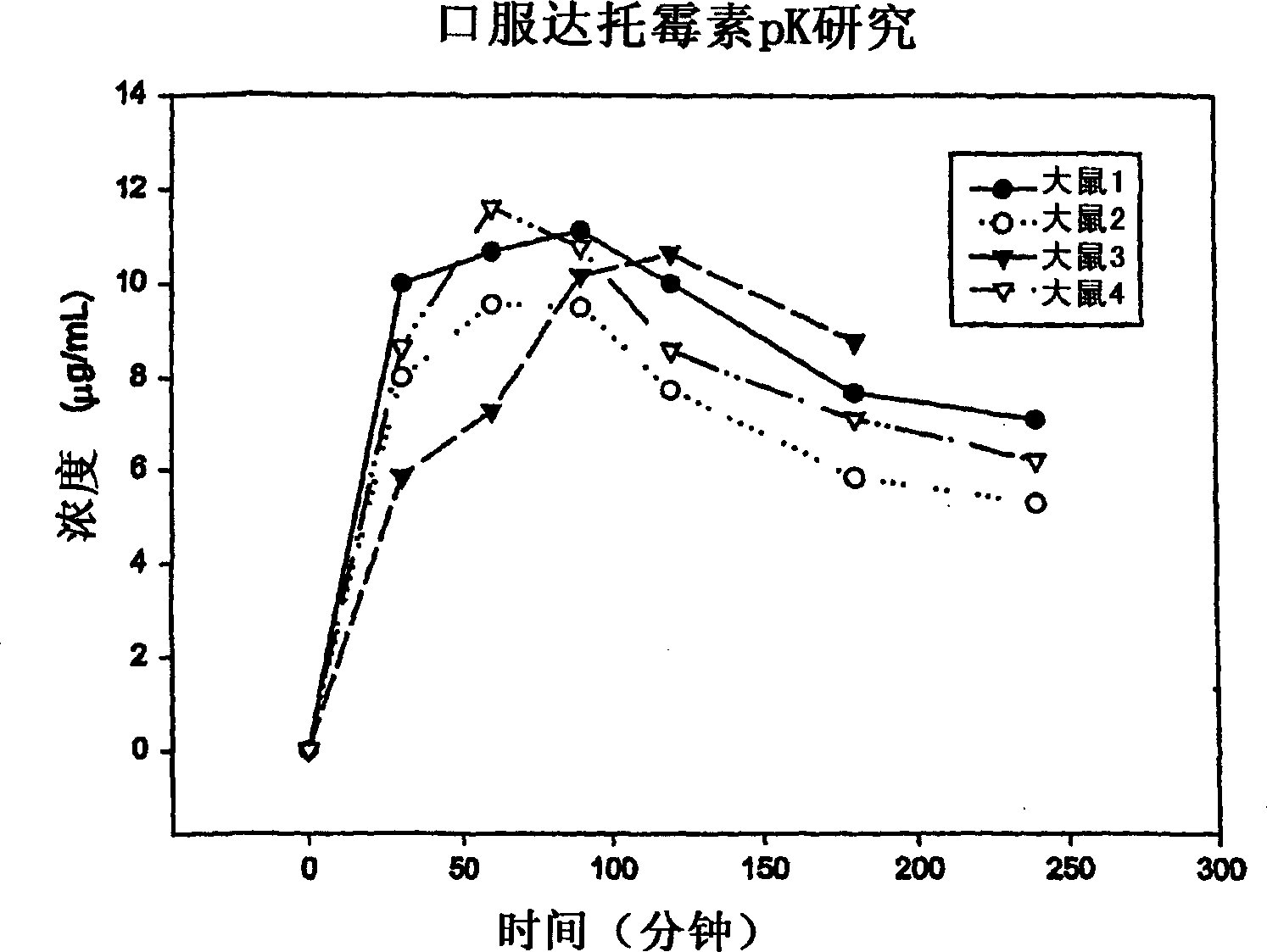

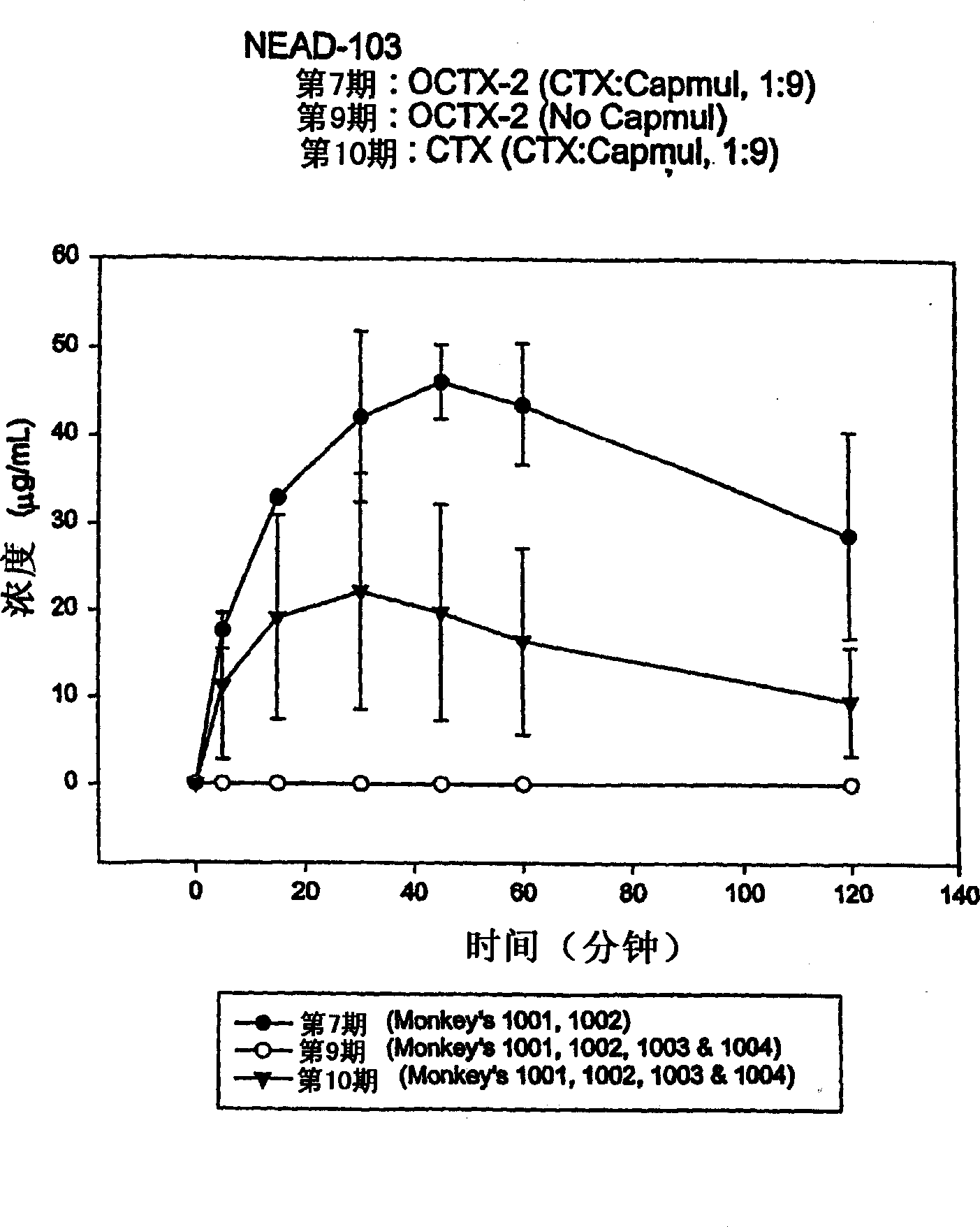

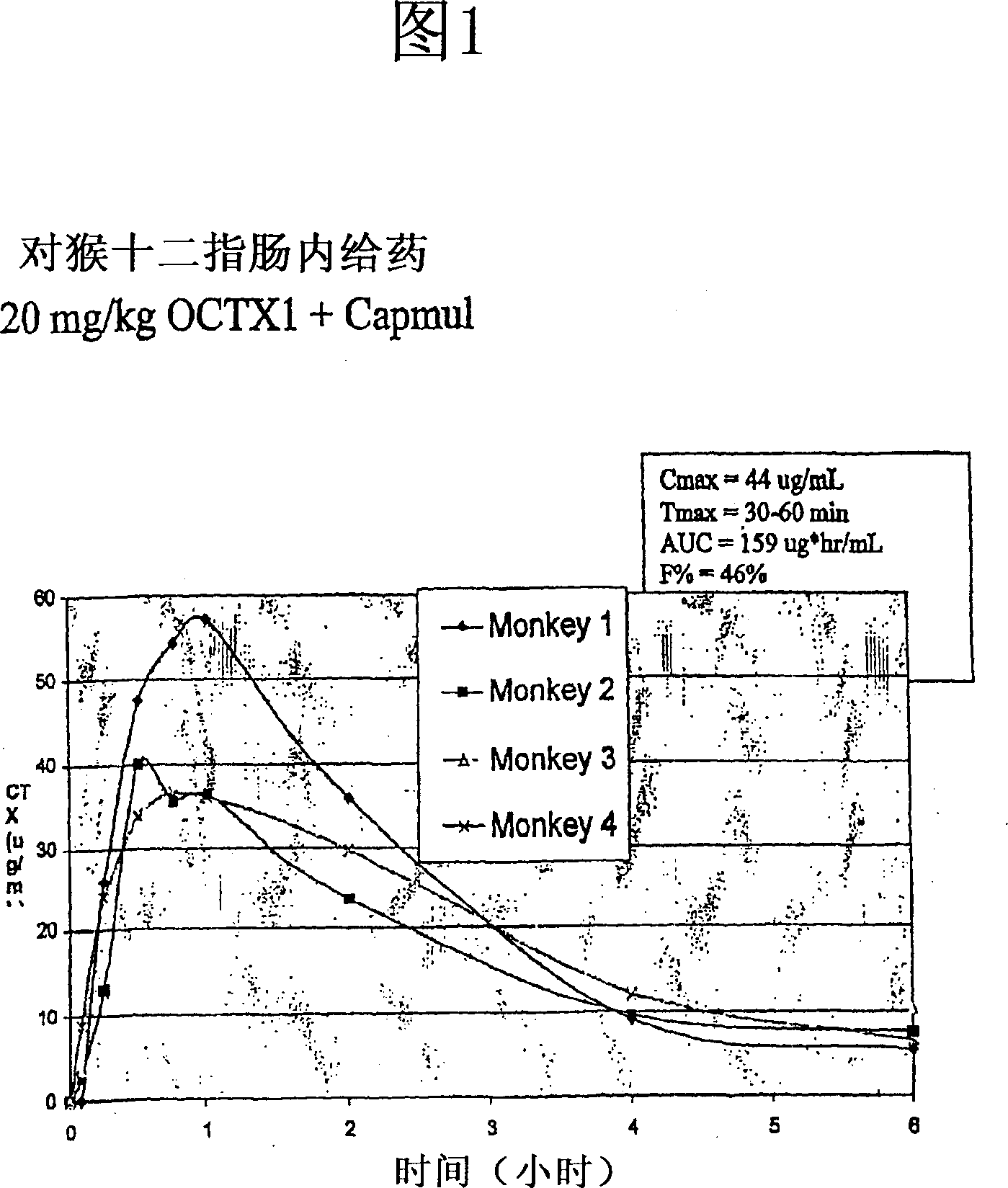

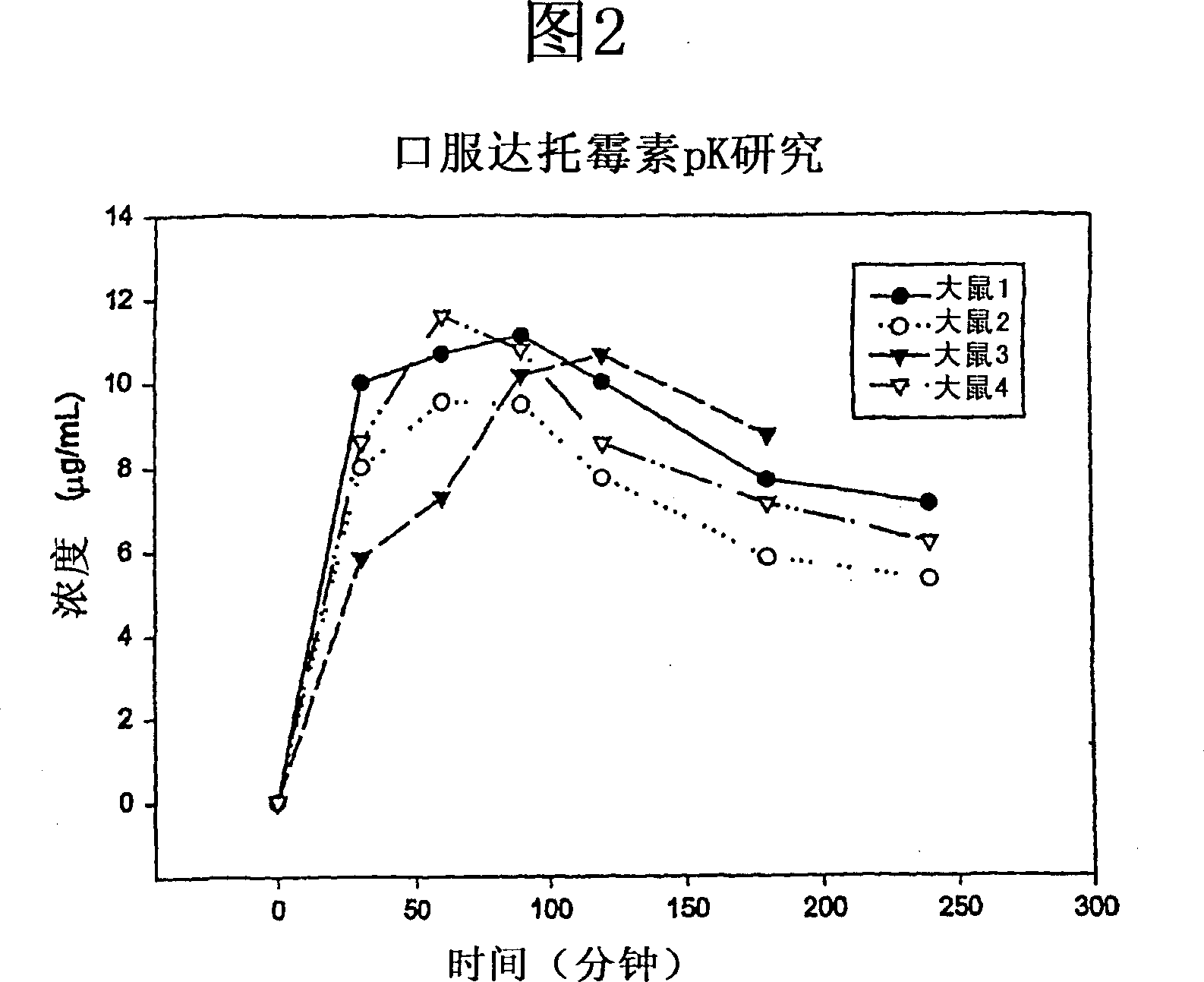

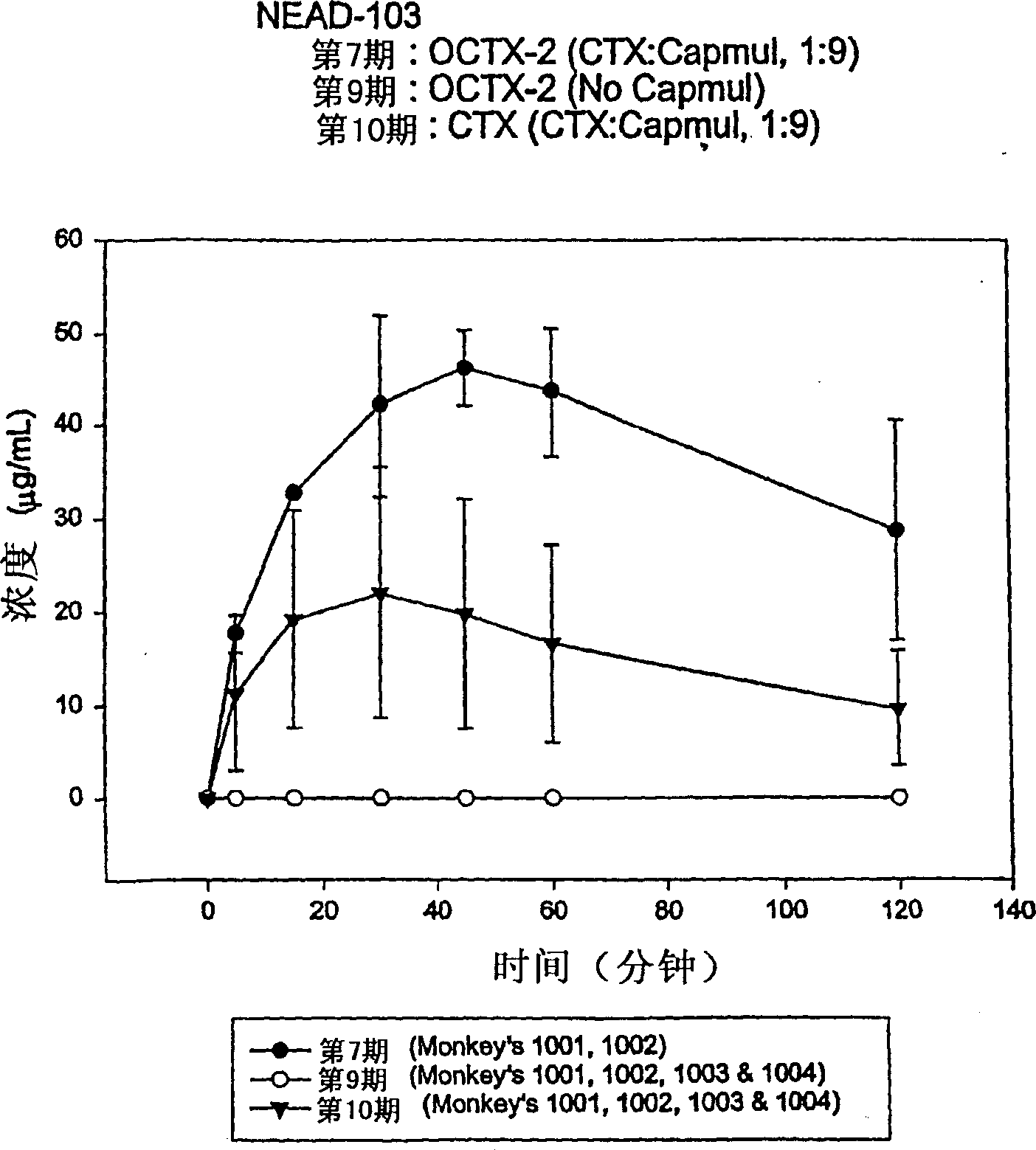

Compositions and methods for increasing the oral absorption of antimicrobials

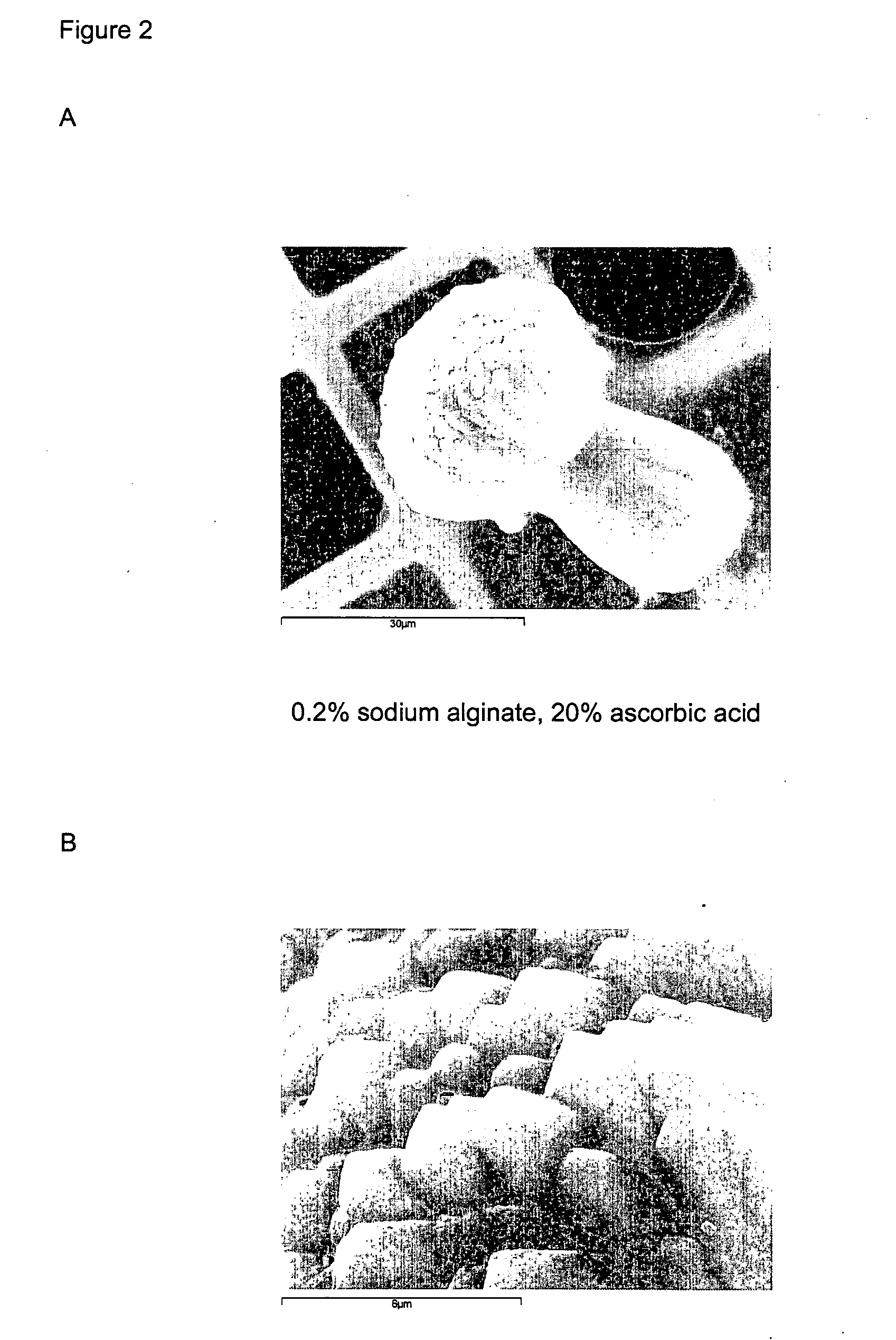

InactiveUS7527807B2Increased systemic uptakePromote absorptionPowder deliveryBiocideMicrobial agentBiopolymer

The present invention provides compositions and methods for increasing absorption of antibacterial agents, particularly third generation cephalosporin antibacterial agents, in oral dosage solid and / or suspension forms. Specifically, the composition is comprised of a biopolymer that is preferably swellable and / or mucoadhesive, a antimicrobial agent, and a cationic binding agent contained within the biopolymer such that the binding agent is tonically bound or complexed to at least one member selected from the group consisting of the biopolymer and the antimicrobial agent.

Owner:MERCK SHARP & DOHME CORP +2

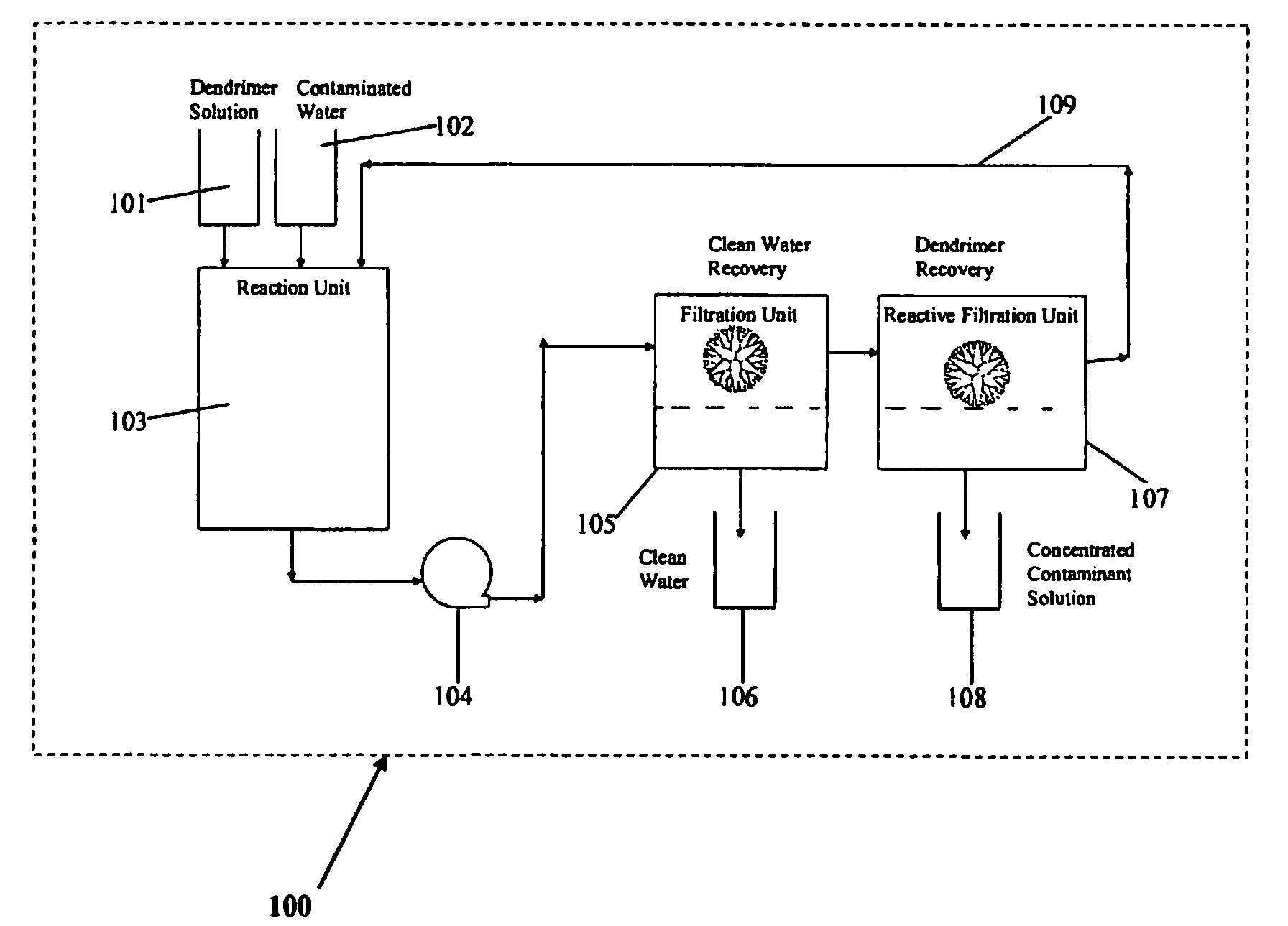

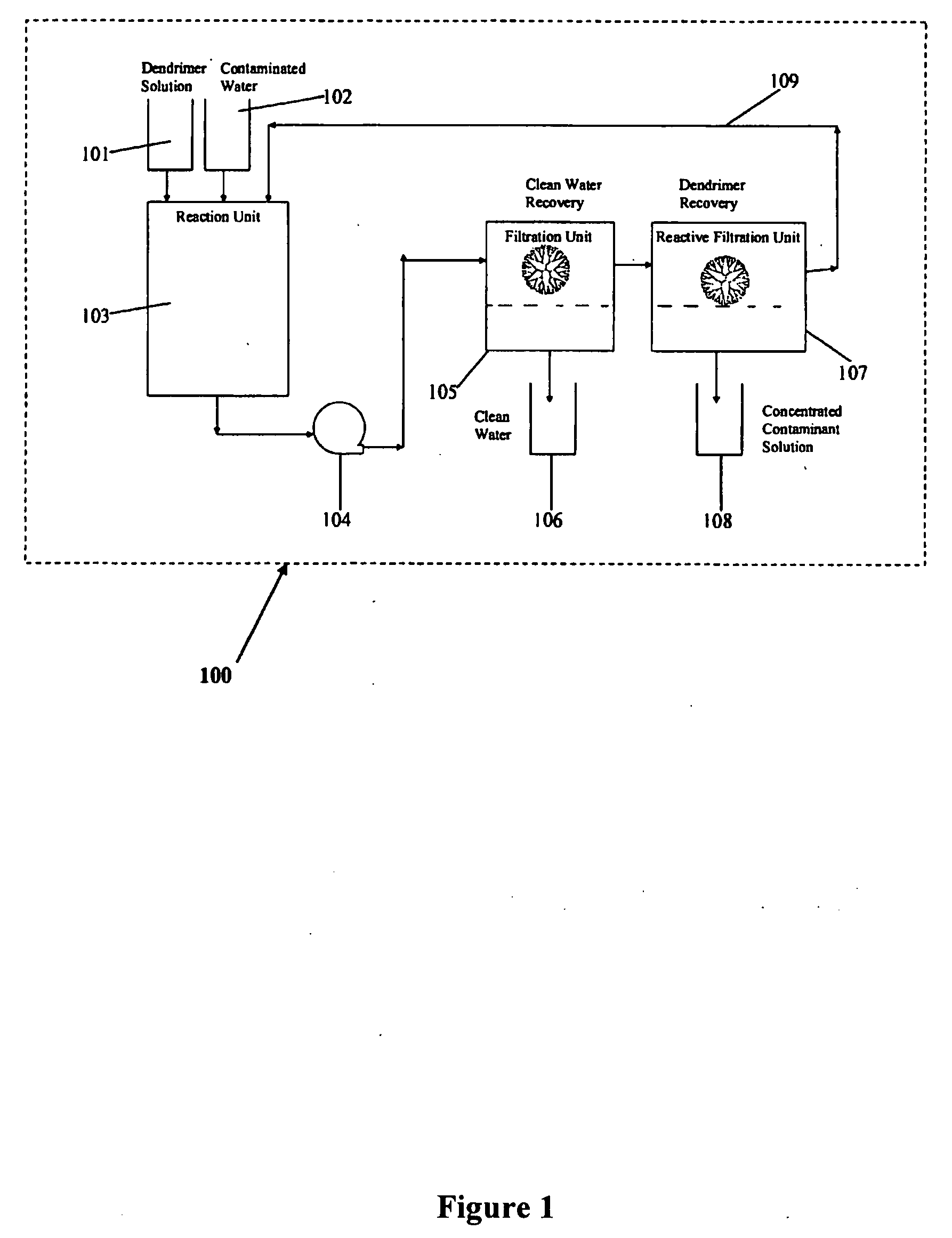

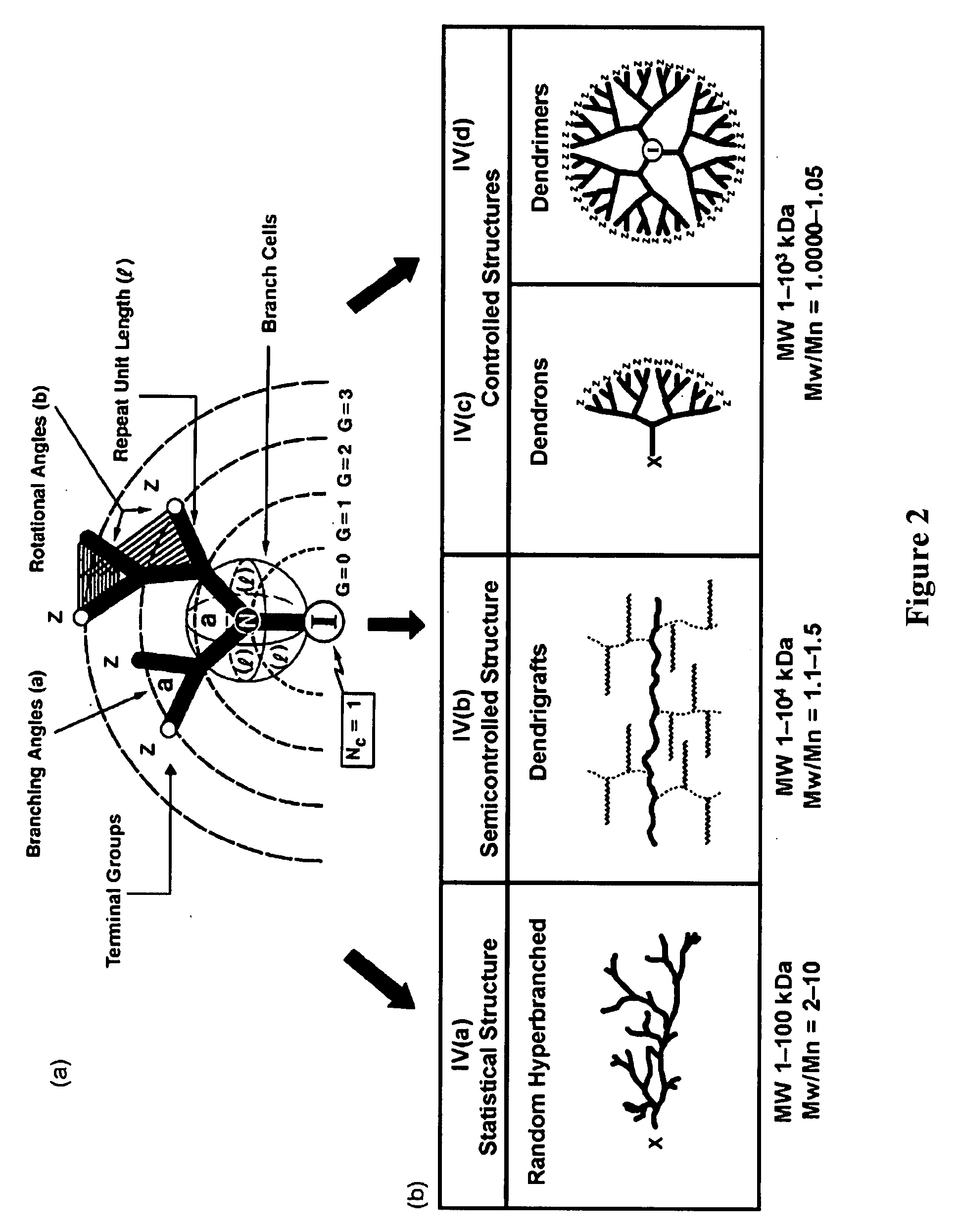

Water treatment by dendrimer enhanced filtration

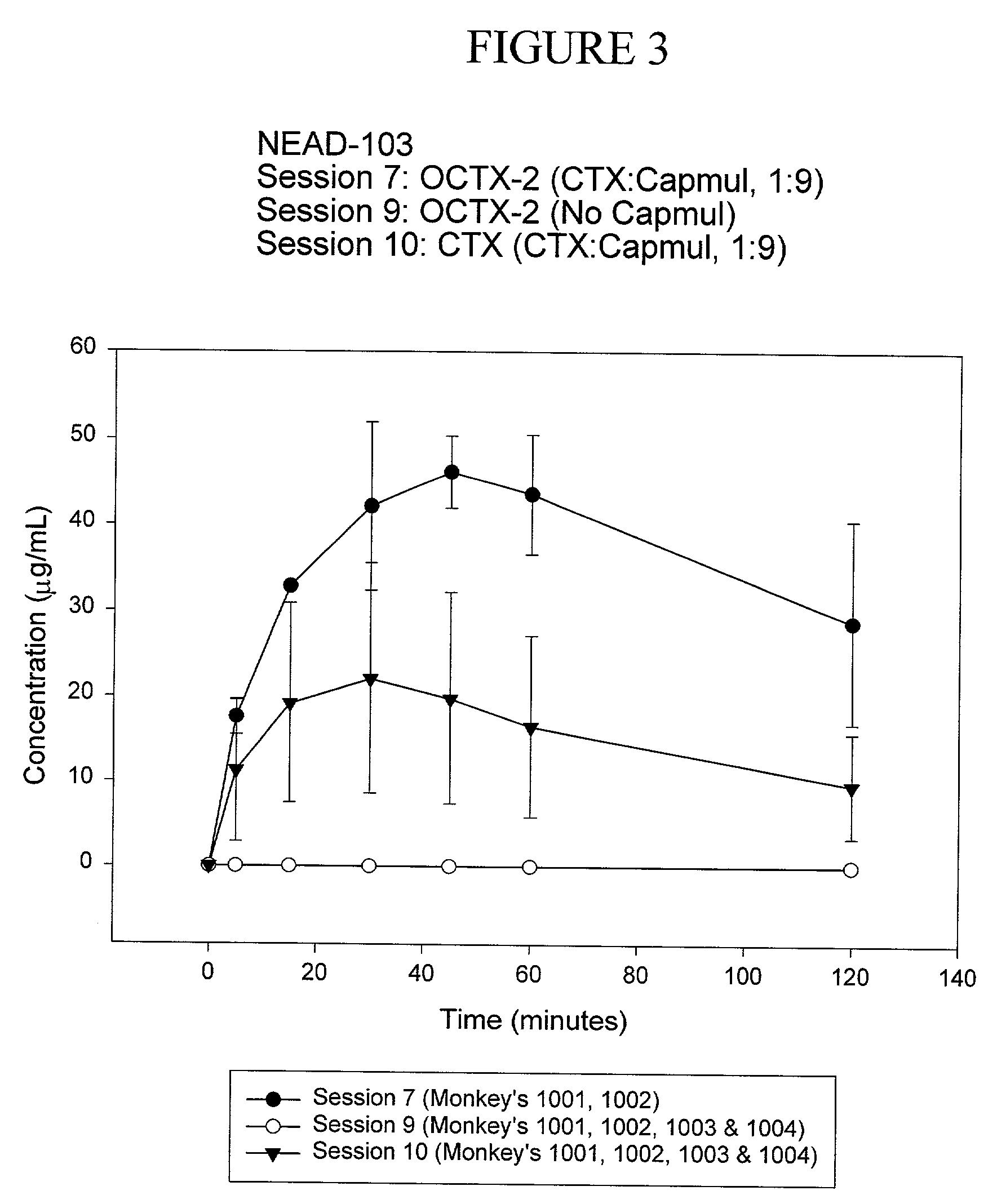

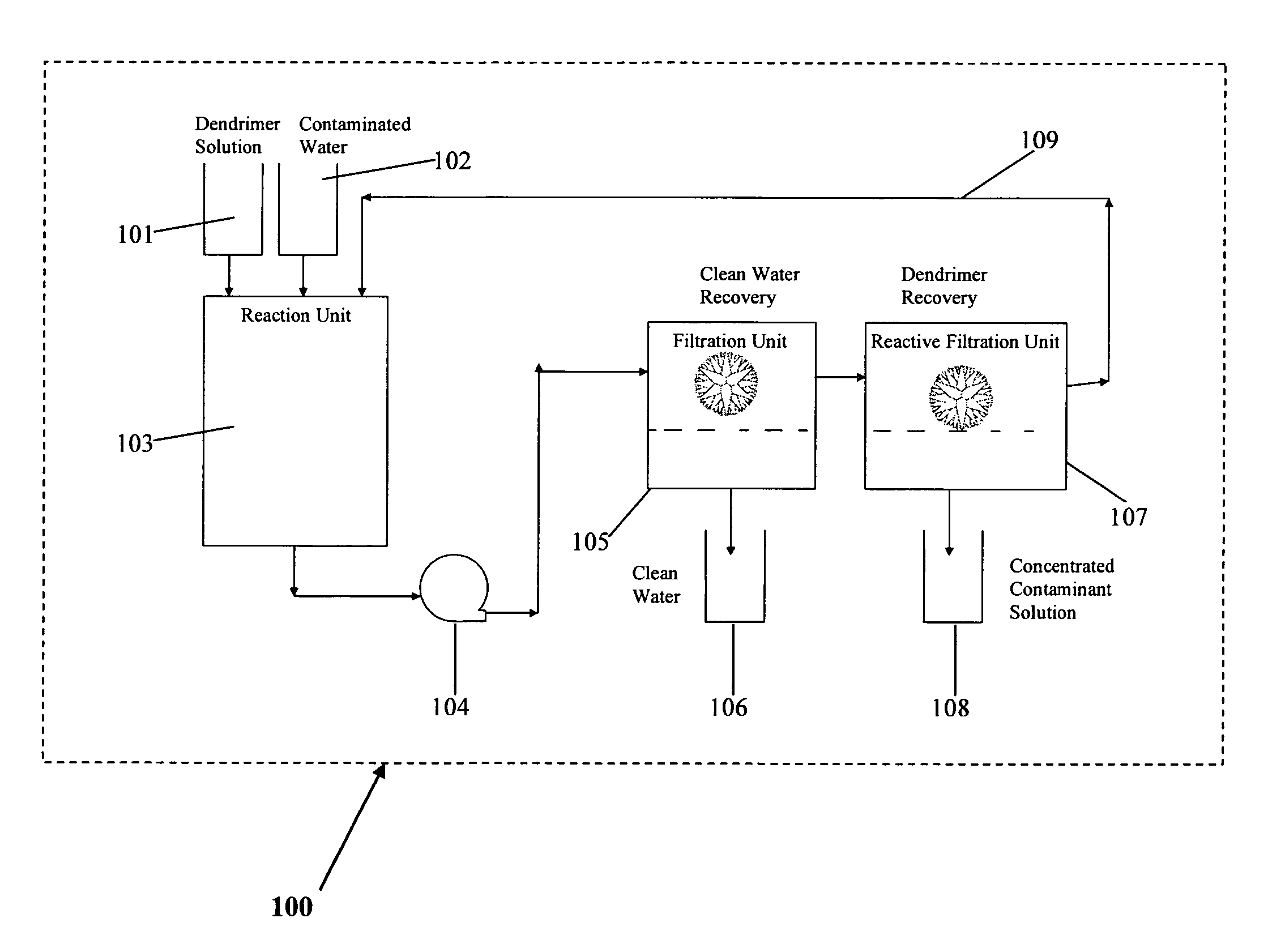

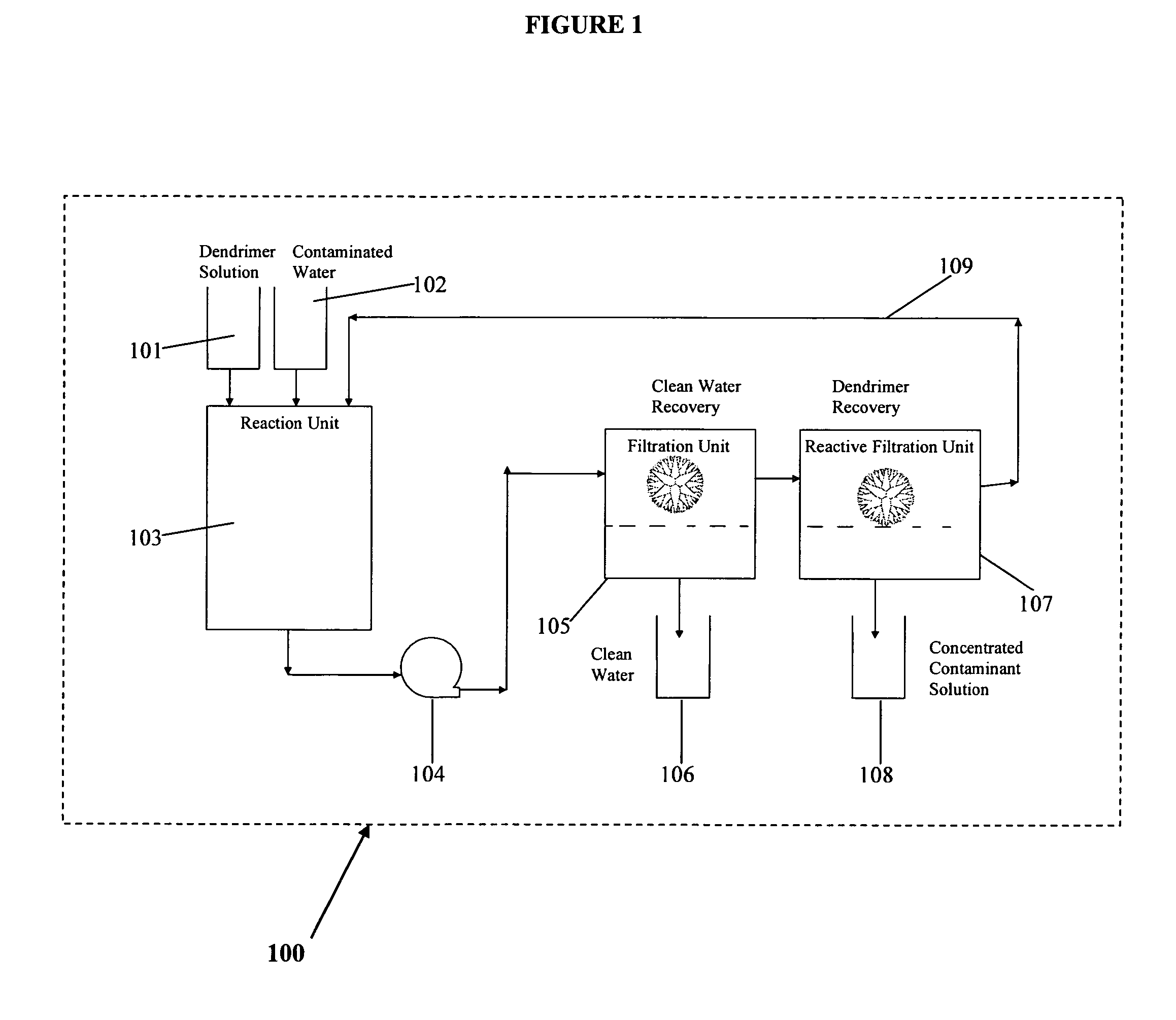

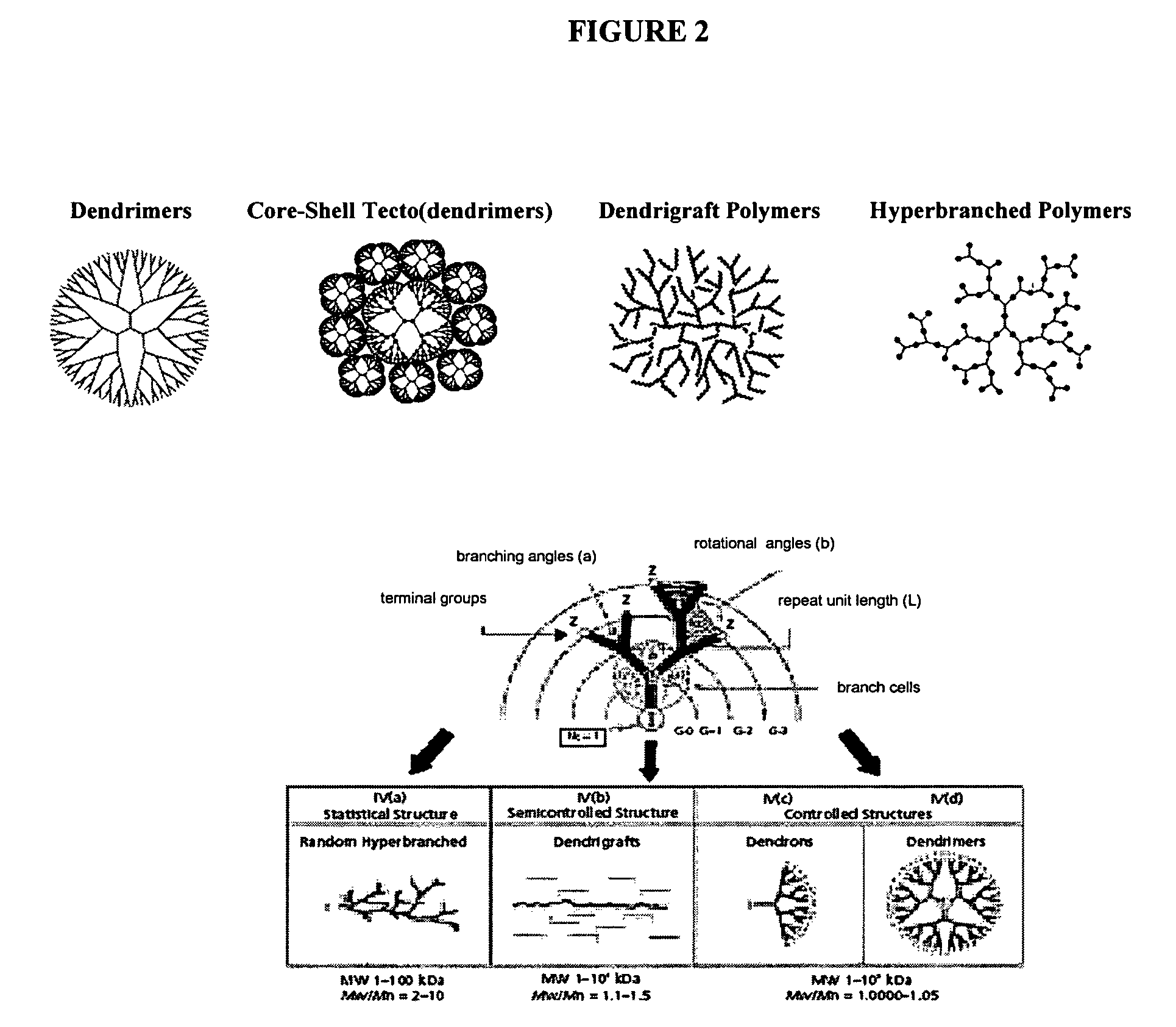

Described herein are compositions and methods useful for the purification of water using dendritic macromolecules. The process involves using dendritic macromolecules (dendrimers) to bind to contaminants, and a filtration step to produce water from which contaminants have been removed or modified. Examples of dendrimers that may be used in the process include cation-binding dendrimers, anion-binding dendrimers, organic compound-binding dendrimers, redox-active dendrimers, biological compound-binding dendrimers, catalytic dendrimers, biocidal dendrimers, viral-binding dendrimers, multi-functional dendrimers, and combinations thereof. The process is readily scalable and provides many options for customization.

Owner:CALIFORNIA INST OF TECH

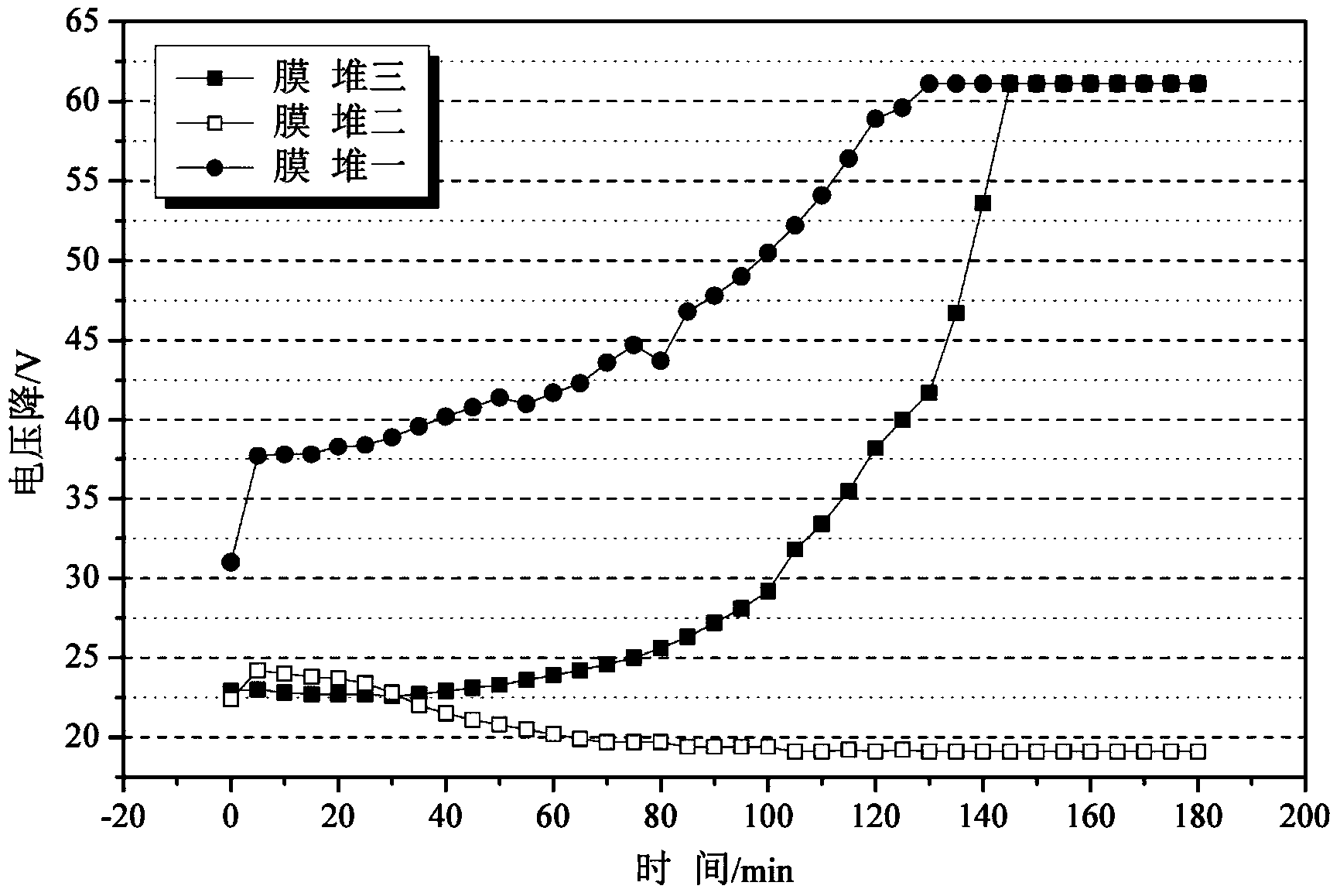

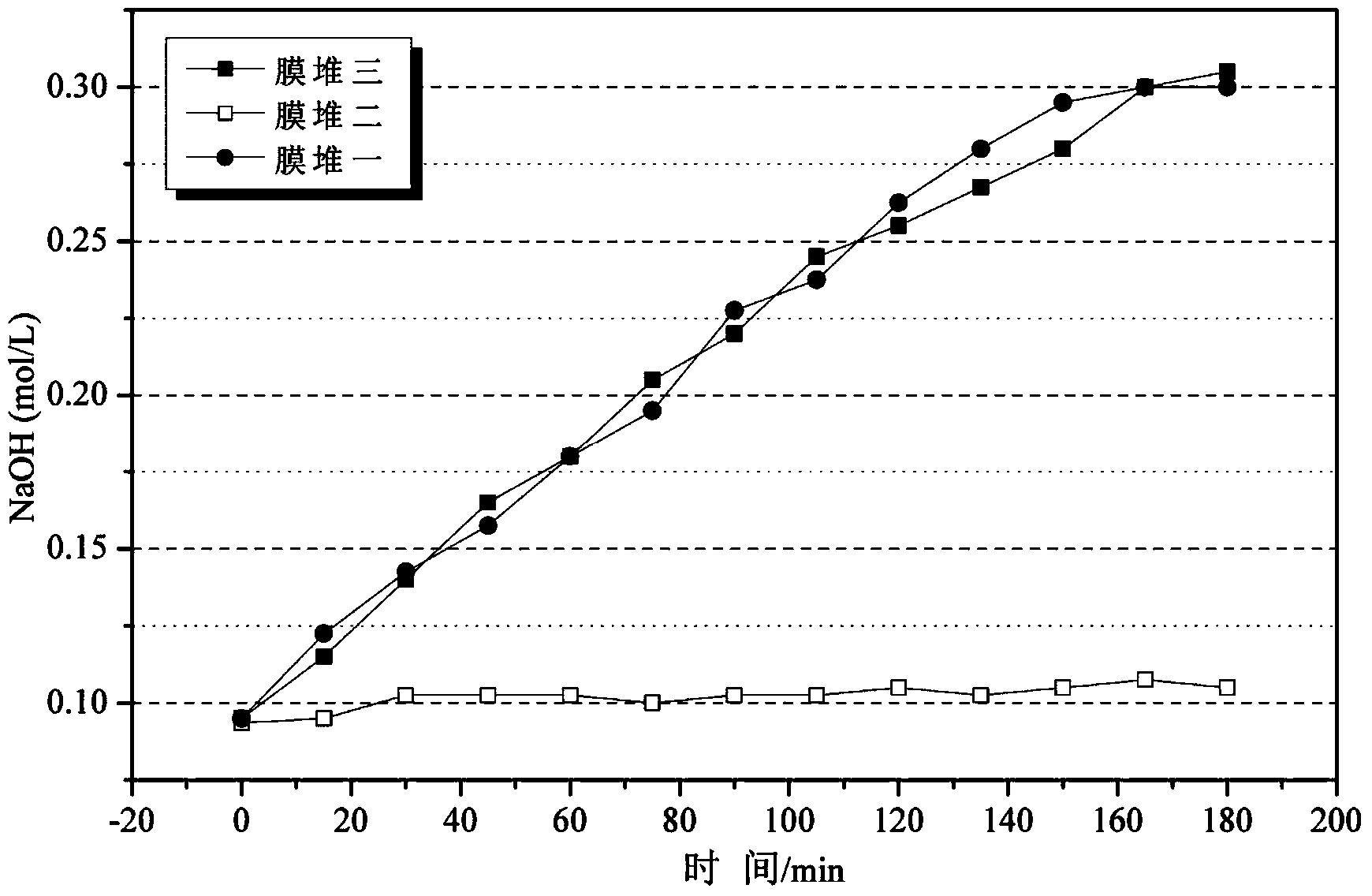

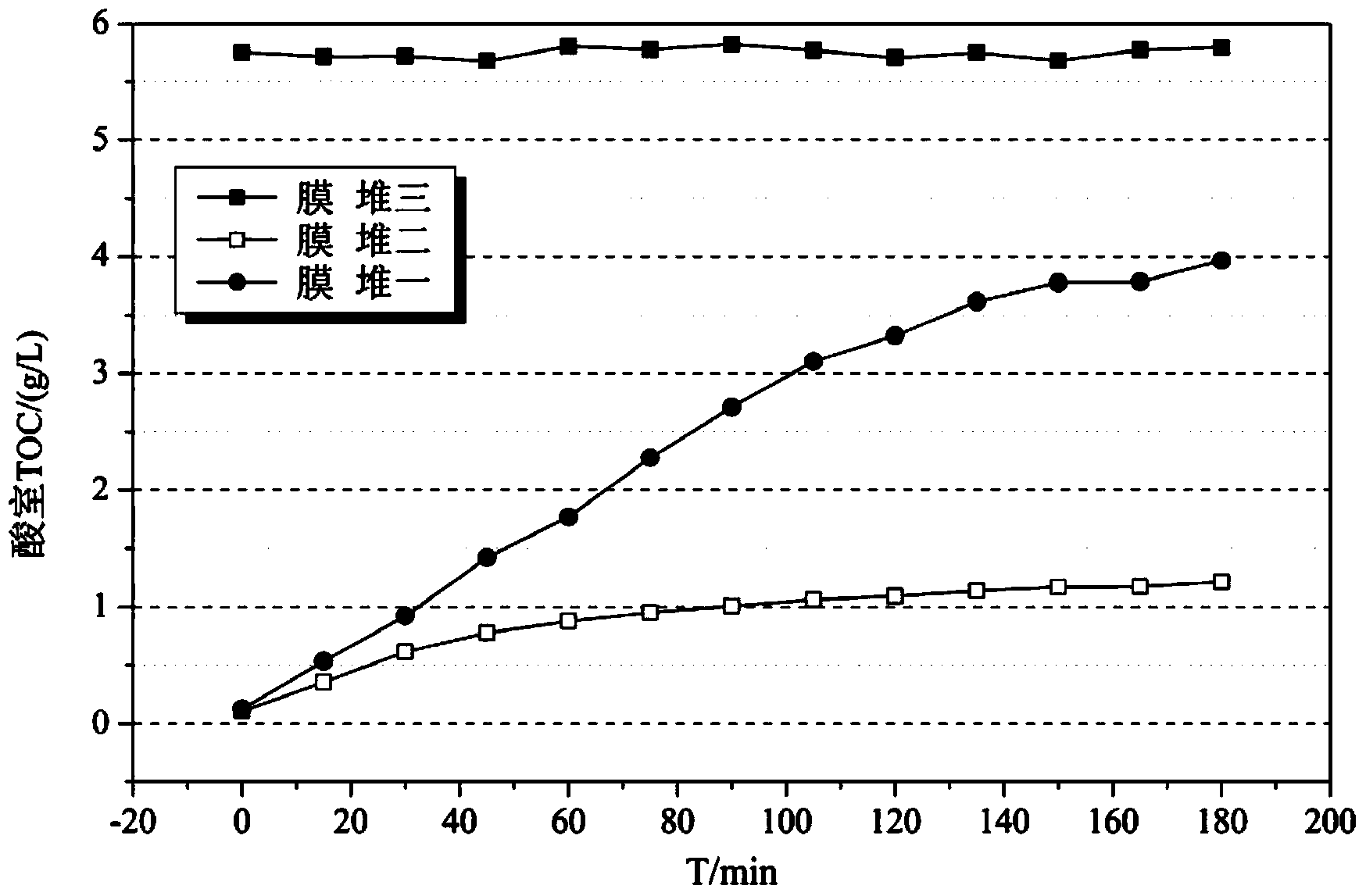

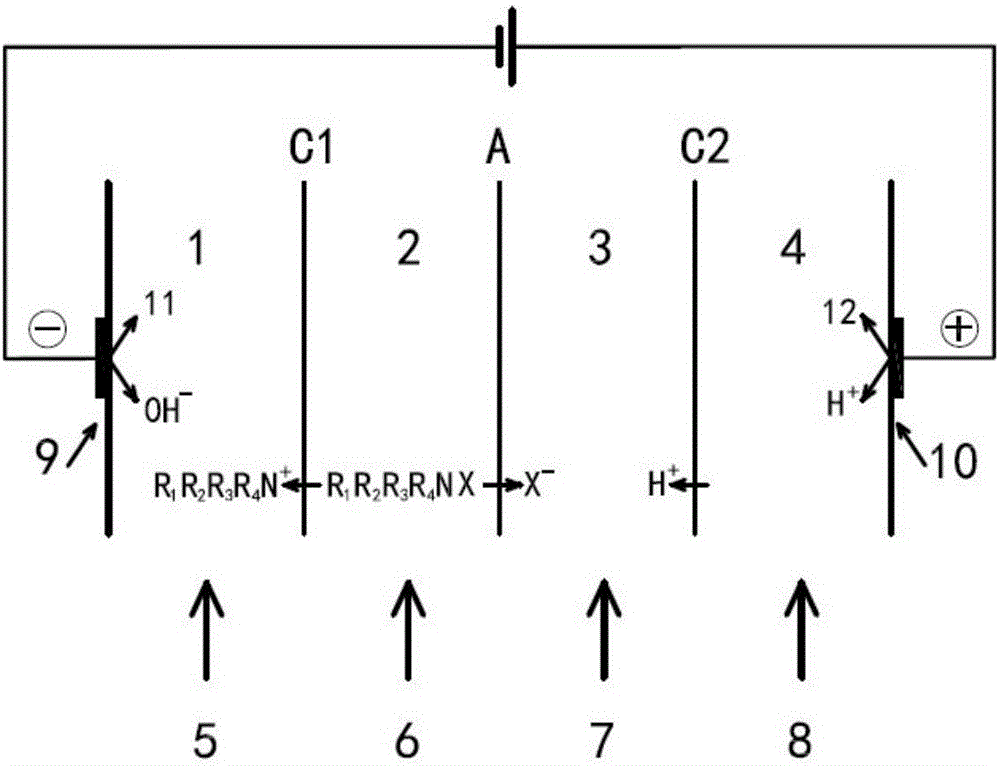

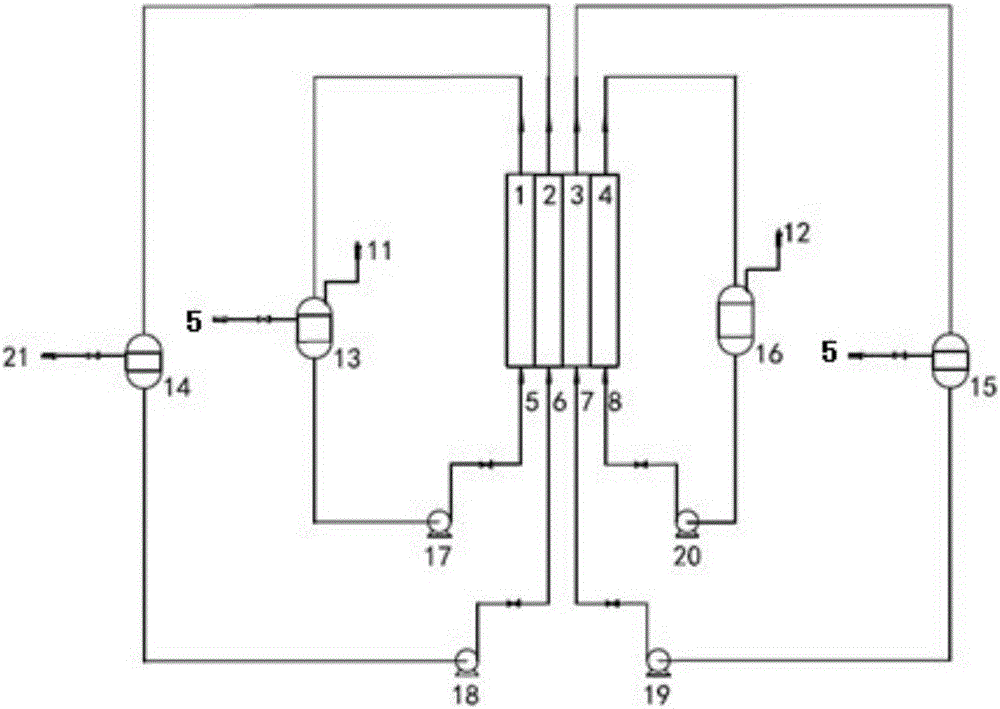

Method for separating methionine from mixed solution of methionine salt and carbonate by using bipolar membrane electrodialysis

The invention discloses a method for separating methionine from a mixed solution of methionine salt and carbonate by using bipolar membrane electrodialysis. The method is characterized by comprising the steps of arranging a bipolar membrane electrodialysis system, and separating methionine from a mixed solution of methionine salt and carbonate by using a bipolar membrane electrodialysis process, wherein a bipolar membrane is capable of simultaneously generating hydroxyl ions and hydrogen ions through hydrolytic dissociation, the hydrogen ions are capable of neutralizing methionine ions and carbanions in the mixed solution of methionine salt and carbonate to generate methionine, and the generated hydroxyl ions are capable of combining with positive ions to obtain inorganic base. According to the method, a large quantity of acid and alkaline are not required to be additionally introduced in the bipolar membrane electrodialysis process, the environment friendliness is achieved, the process cost is lowered, no inorganic salt waste residue is generated in the process, the recovery efficiency of methionine is high, and the purity is high, thus the generated wastewater is more easily treated.

Owner:UNIV OF SCI & TECH OF CHINA

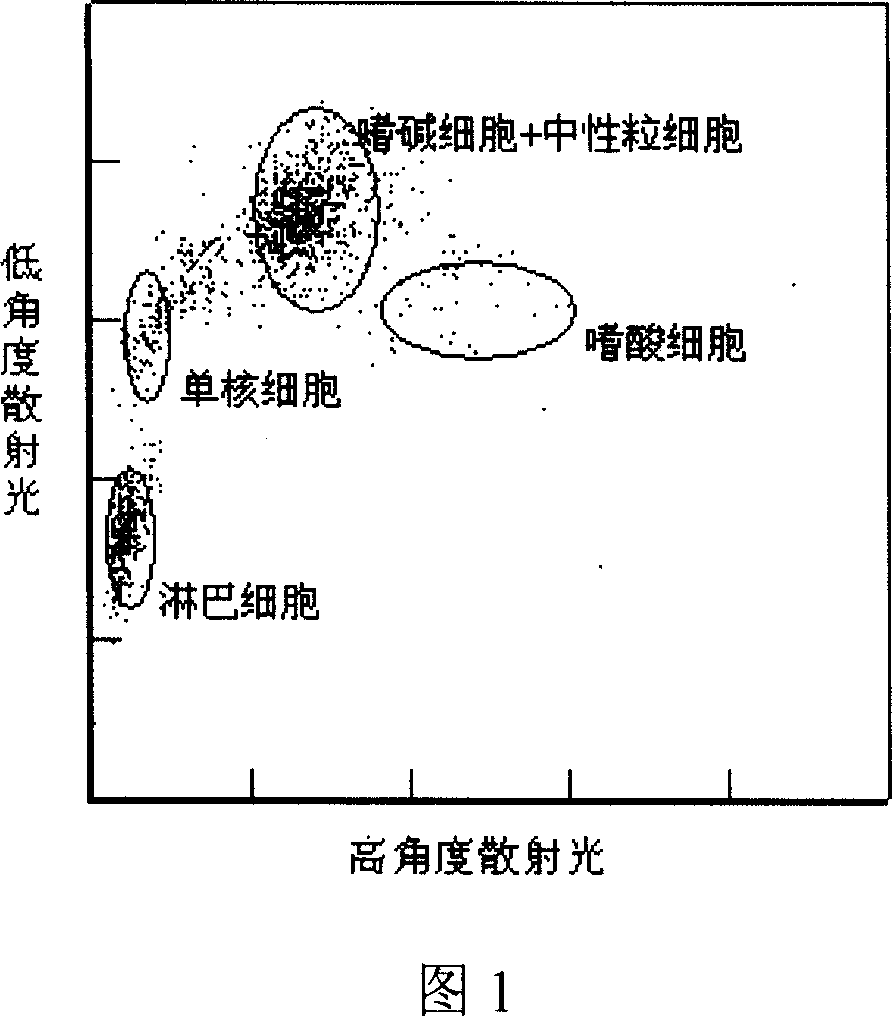

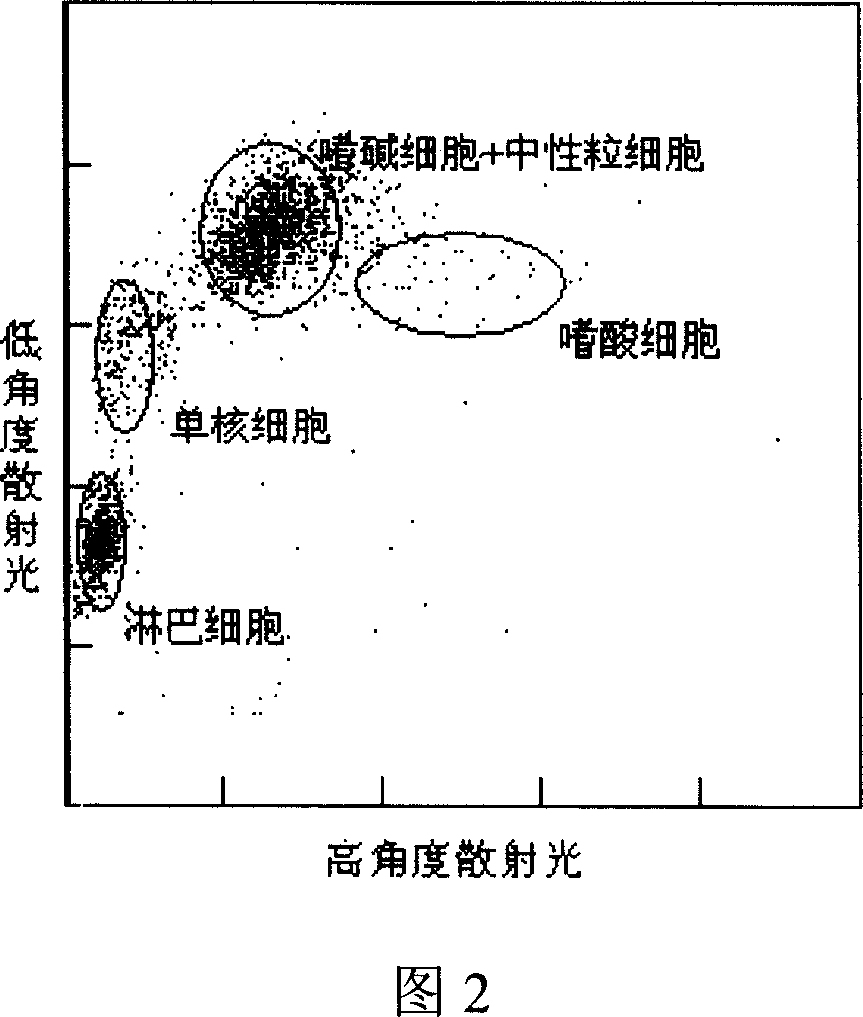

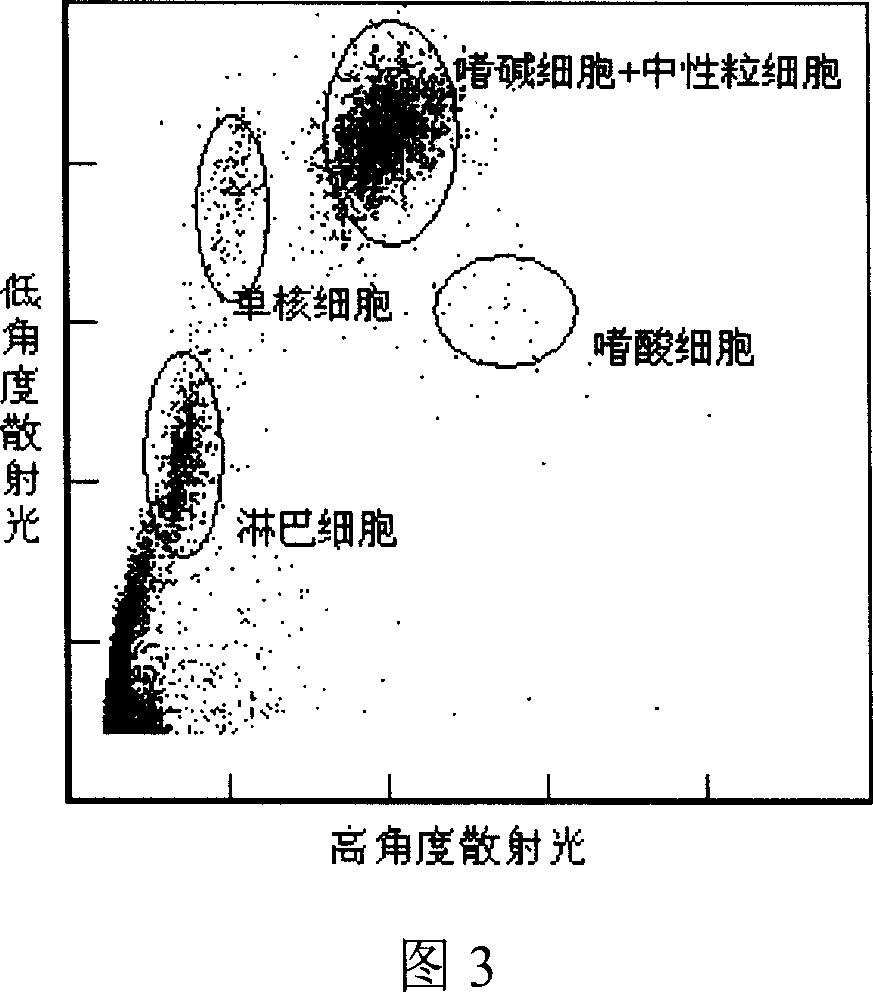

Reagent and method for classifying leucocyte

ActiveCN101078721AGuaranteed accuracyLow costIndividual particle analysisBiological testingWhite blood cellActive agent

The invention discloses a reagent for four-classification of leukocyte. The reagent comprises a. at least a surfactant which can dissolve erythrocyte and destroy leukocyte membrane; b. at least an organic compound with anionic group which can combine with cationic in leukocyte and make leukocytes generate configuration difference; c. buffering agent which can adjust PH value in 2-8. The invention also discloses the method for four-classification by said reagent. When four-classification of leukocyte is carried out by using the reagent and the method in invention, reaction can be carried out under the condition from acidity to weak alkaline PH and temperature and class of main component surfactant all have very wide selecting range so that the application range of invention is developed greatly. Compared with prior technology it has a great improvement.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

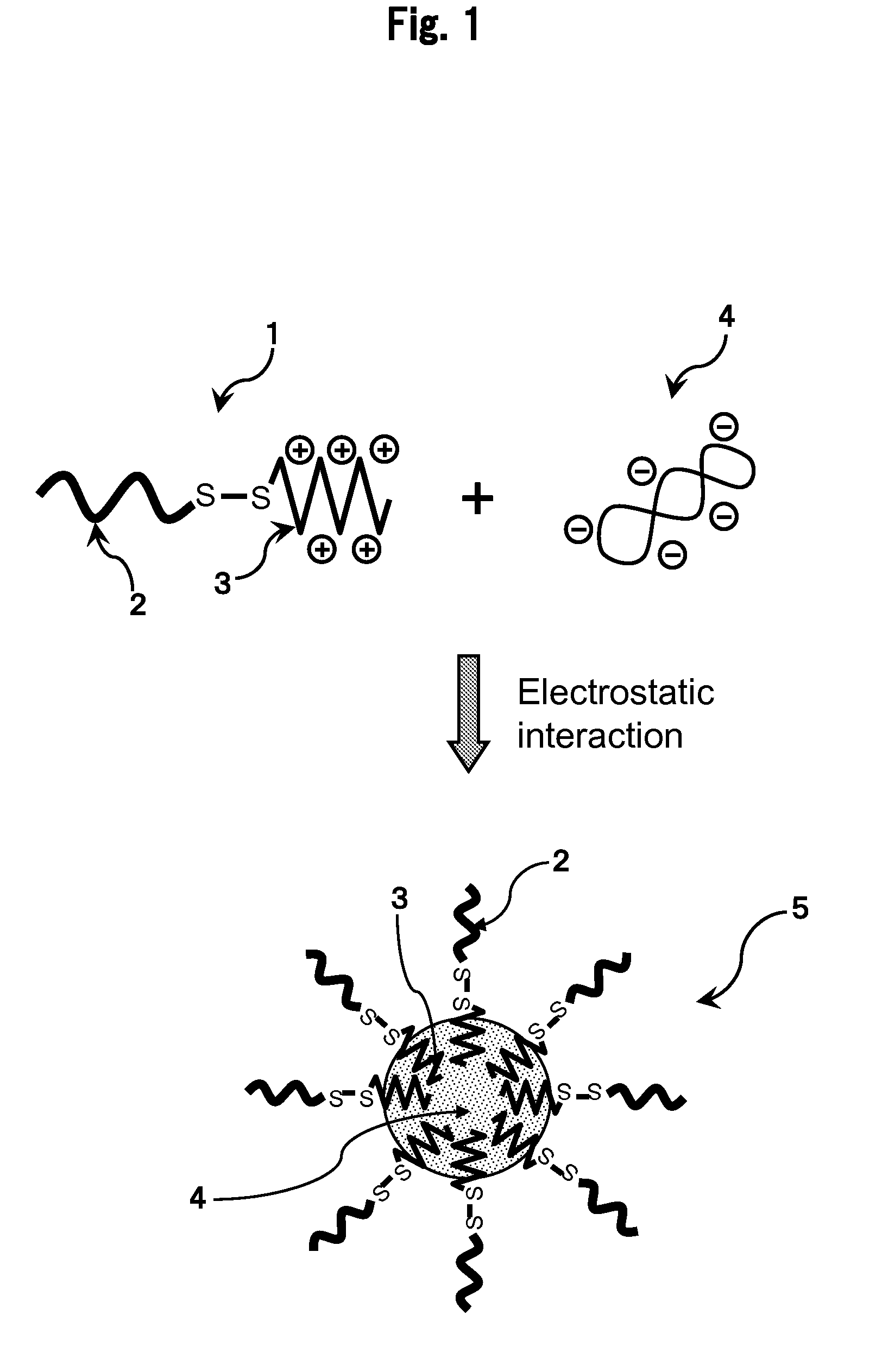

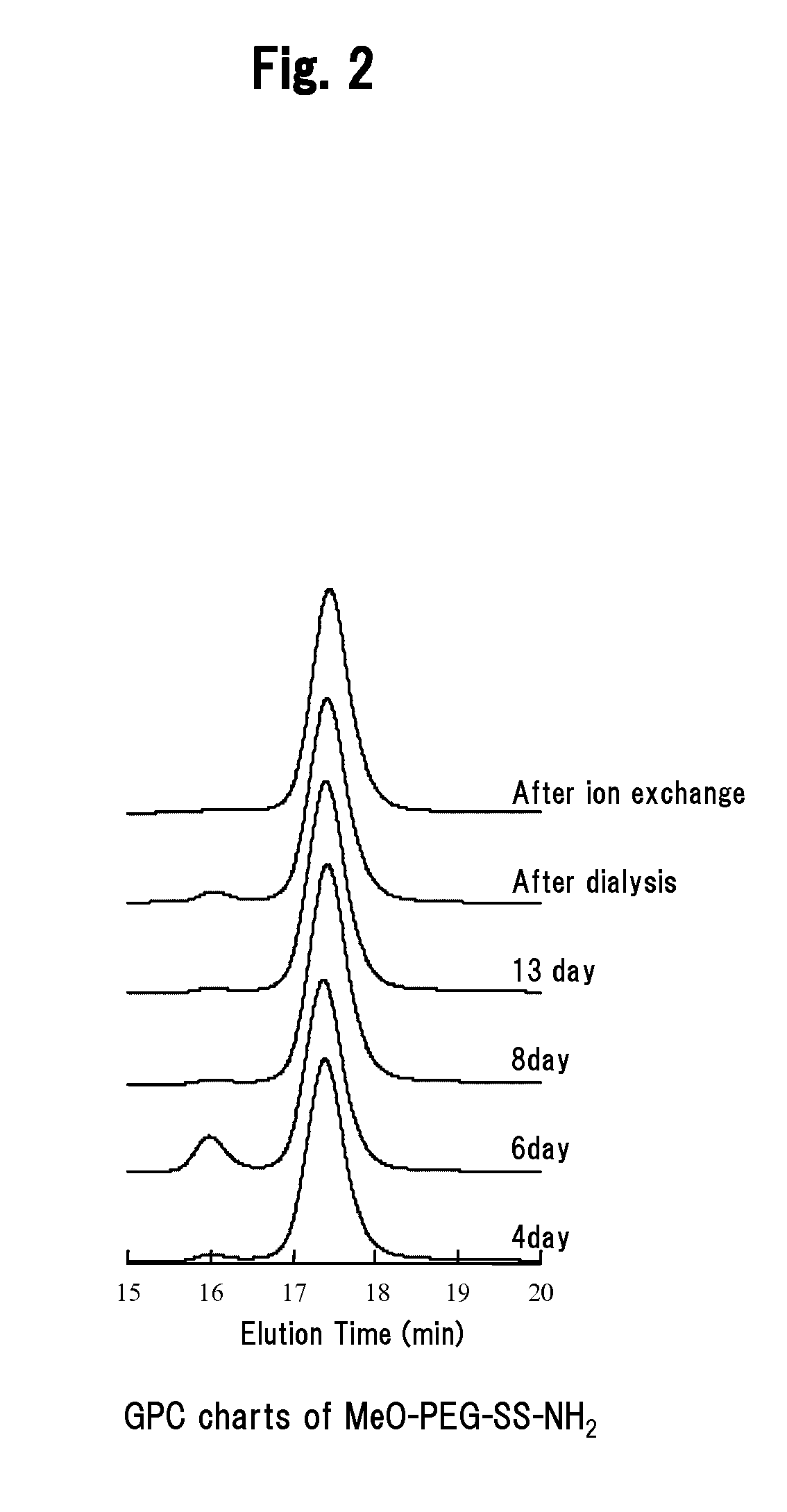

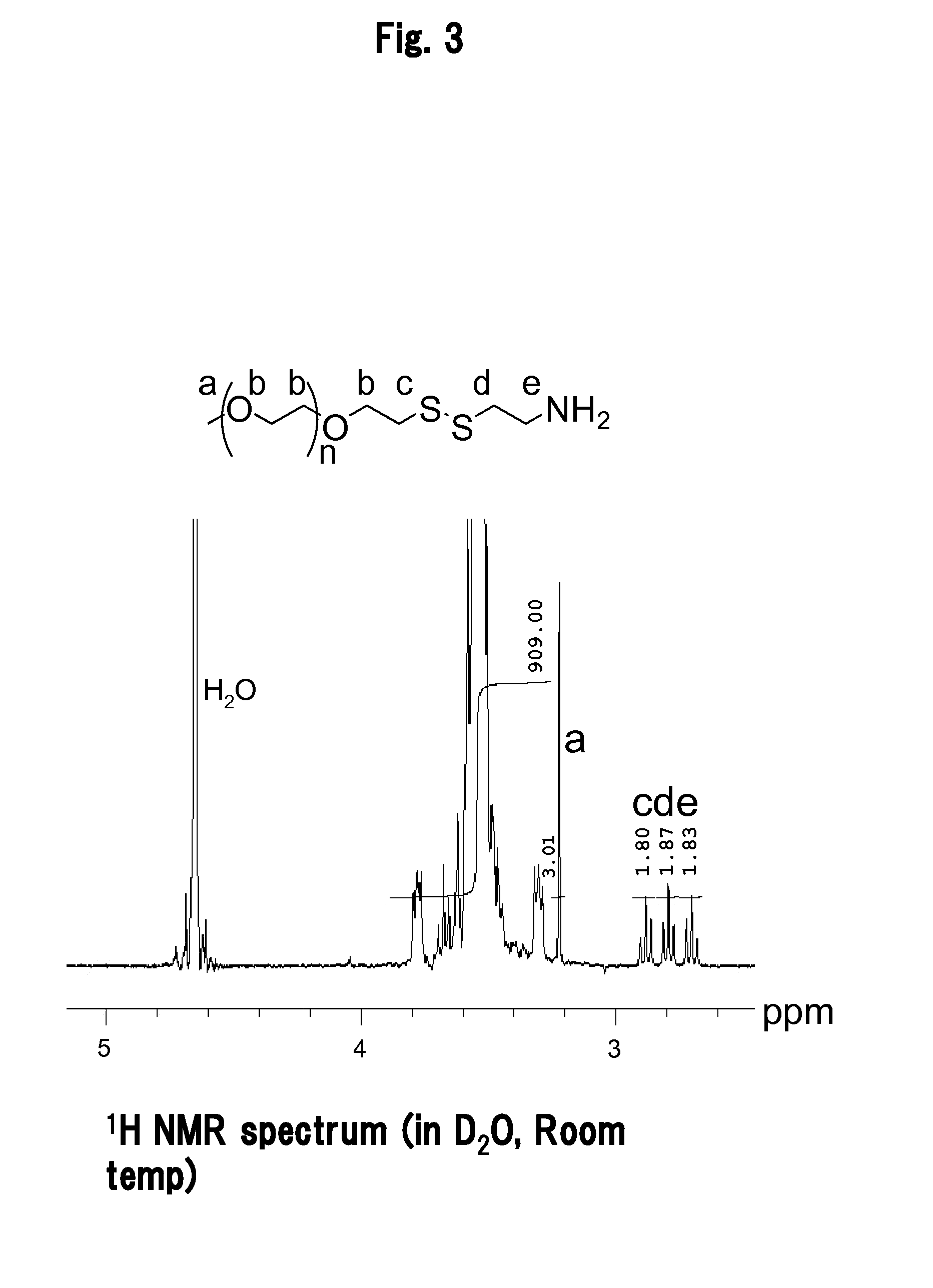

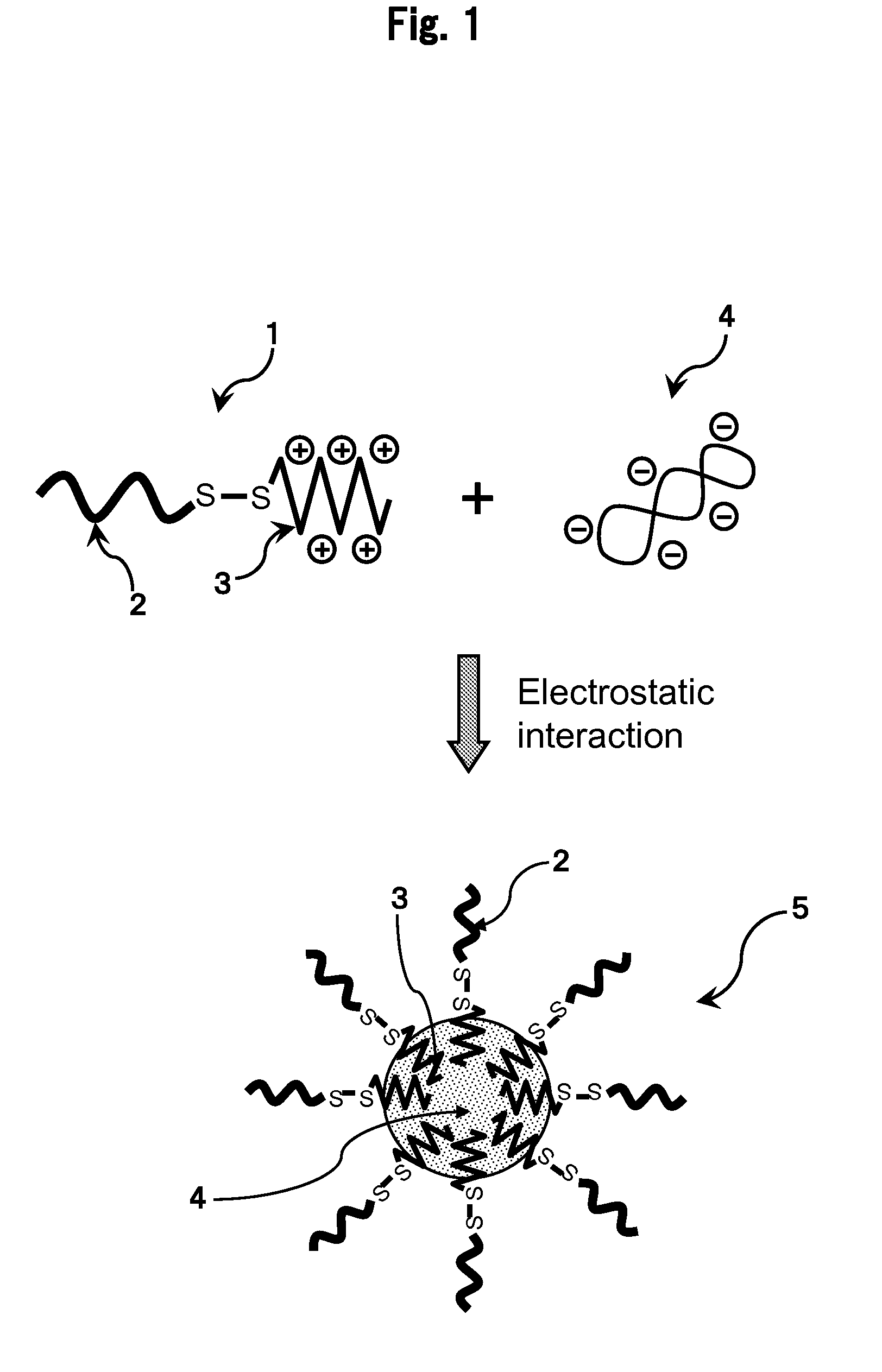

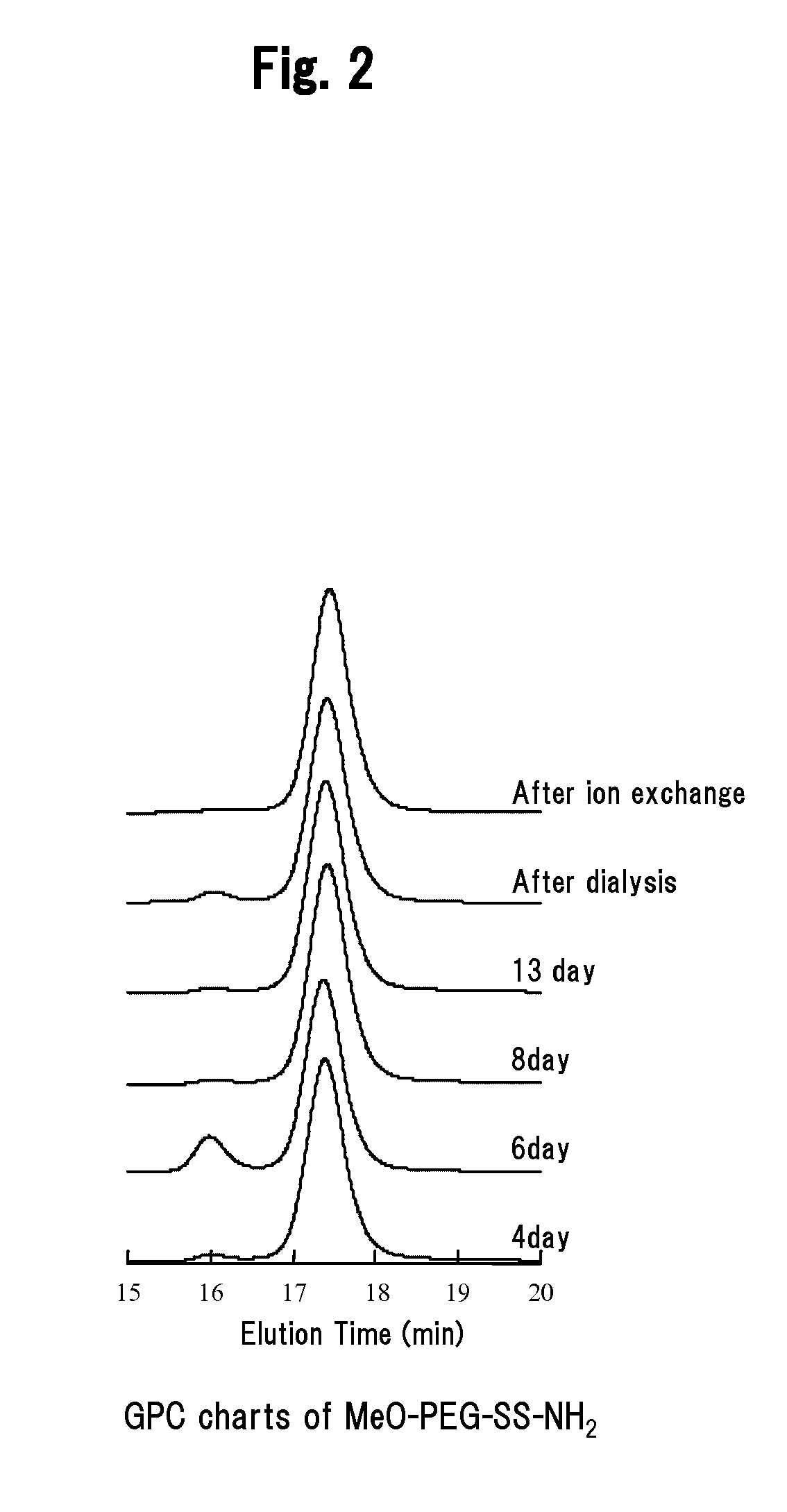

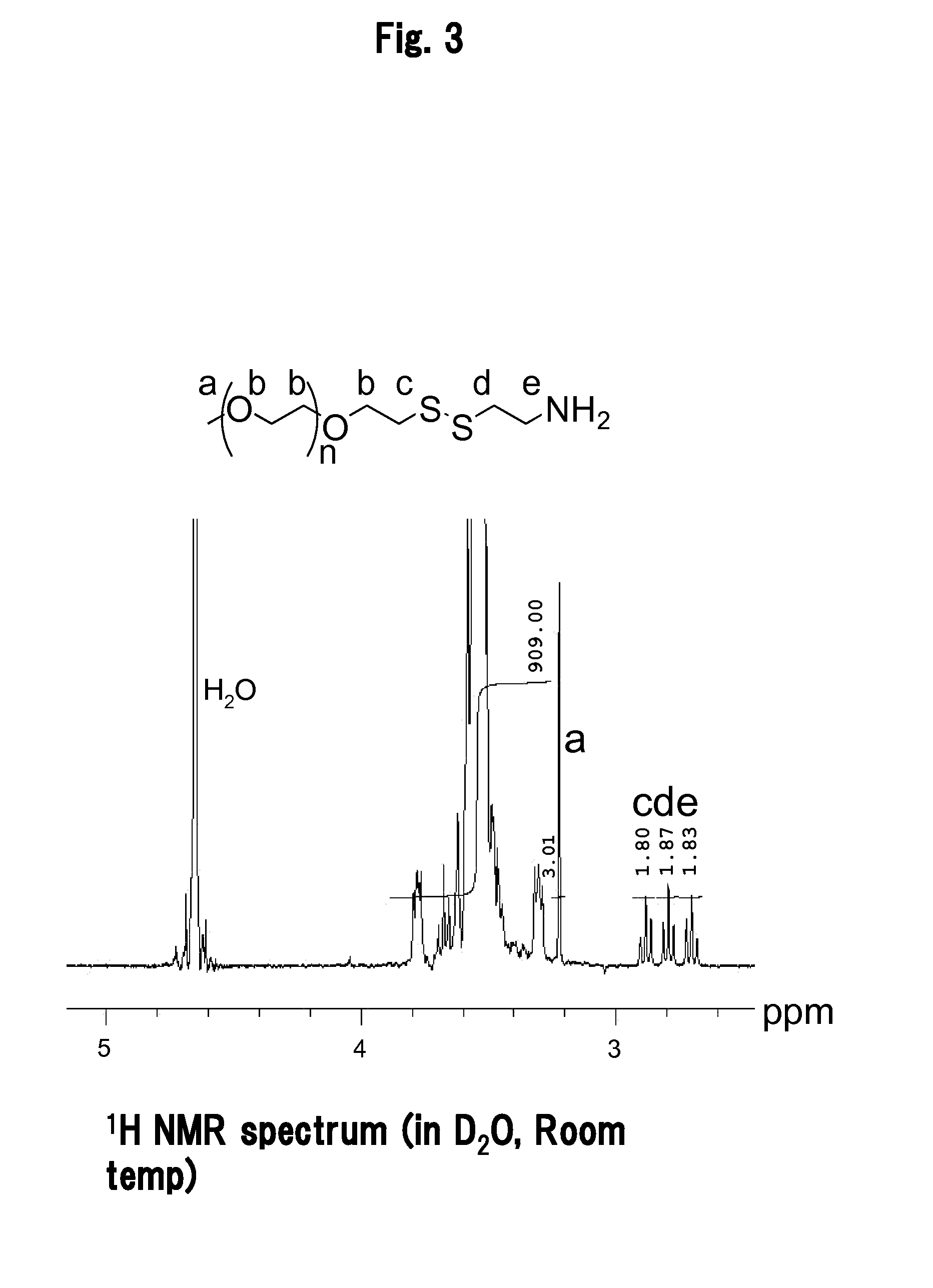

Polymer micelle complex including nucleic acid

ActiveUS20090258416A1Efficient expressionMicroencapsulation basedGenetic material ingredientsViral GenesPolyethylene glycol

It is an object of the present invention to provide a polyion complex used as a non-viral gene vector, which achieves sufficiently high gene expression efficiency to a target cell. The polyion complex of the present invention comprises a block copolymer formed by binding polyethylene glycol to polycation via a disulfide group and a nucleic acid.

Owner:THE UNIV OF TOKYO

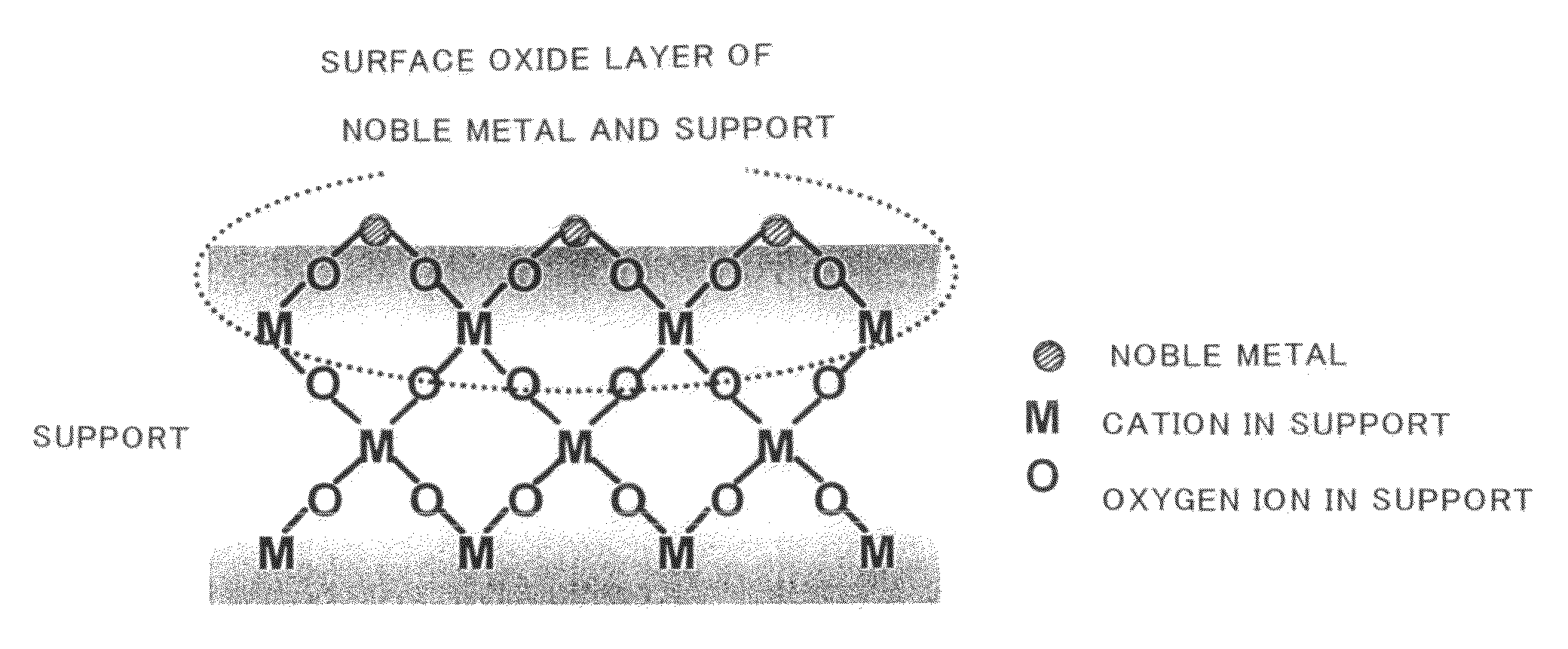

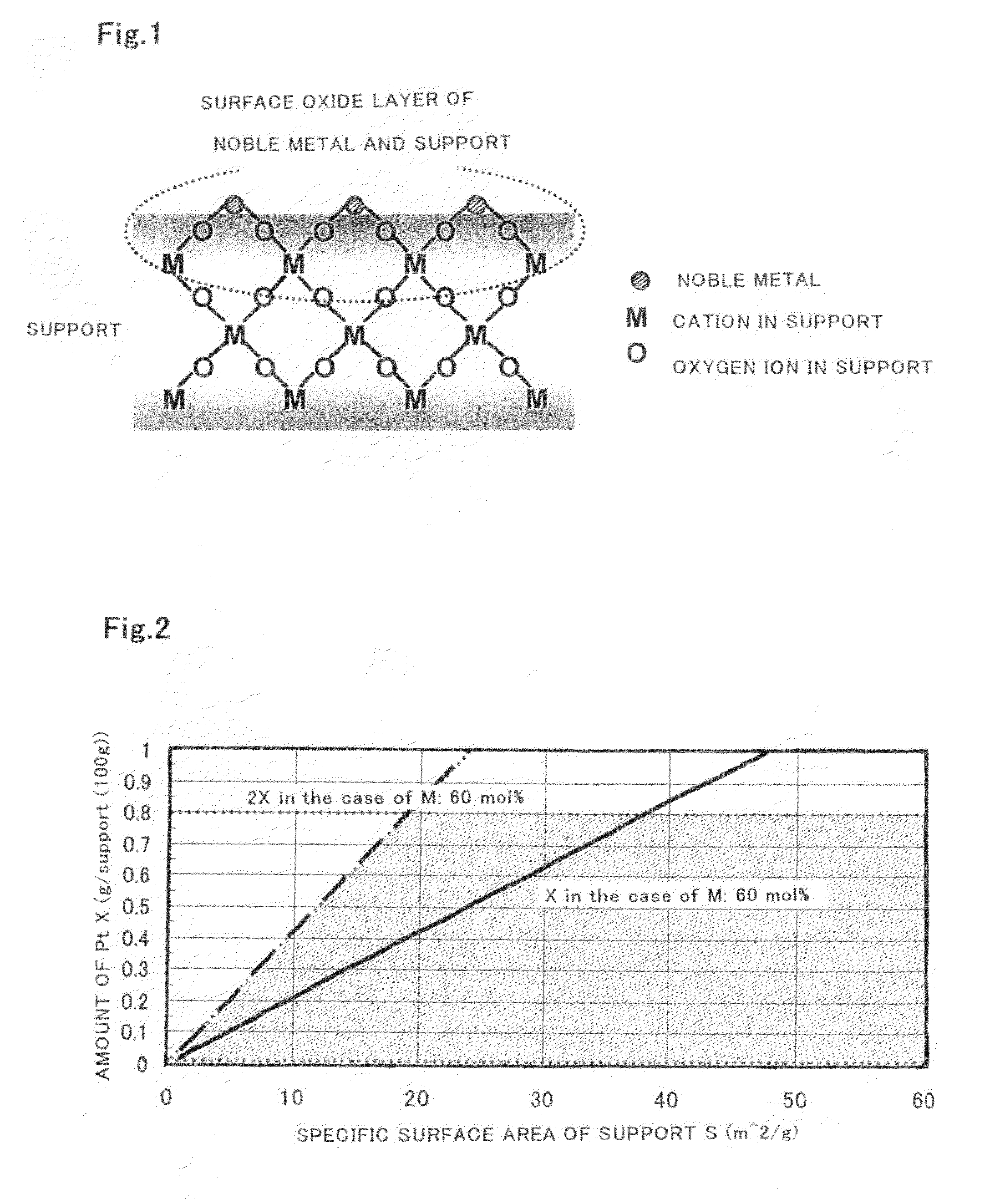

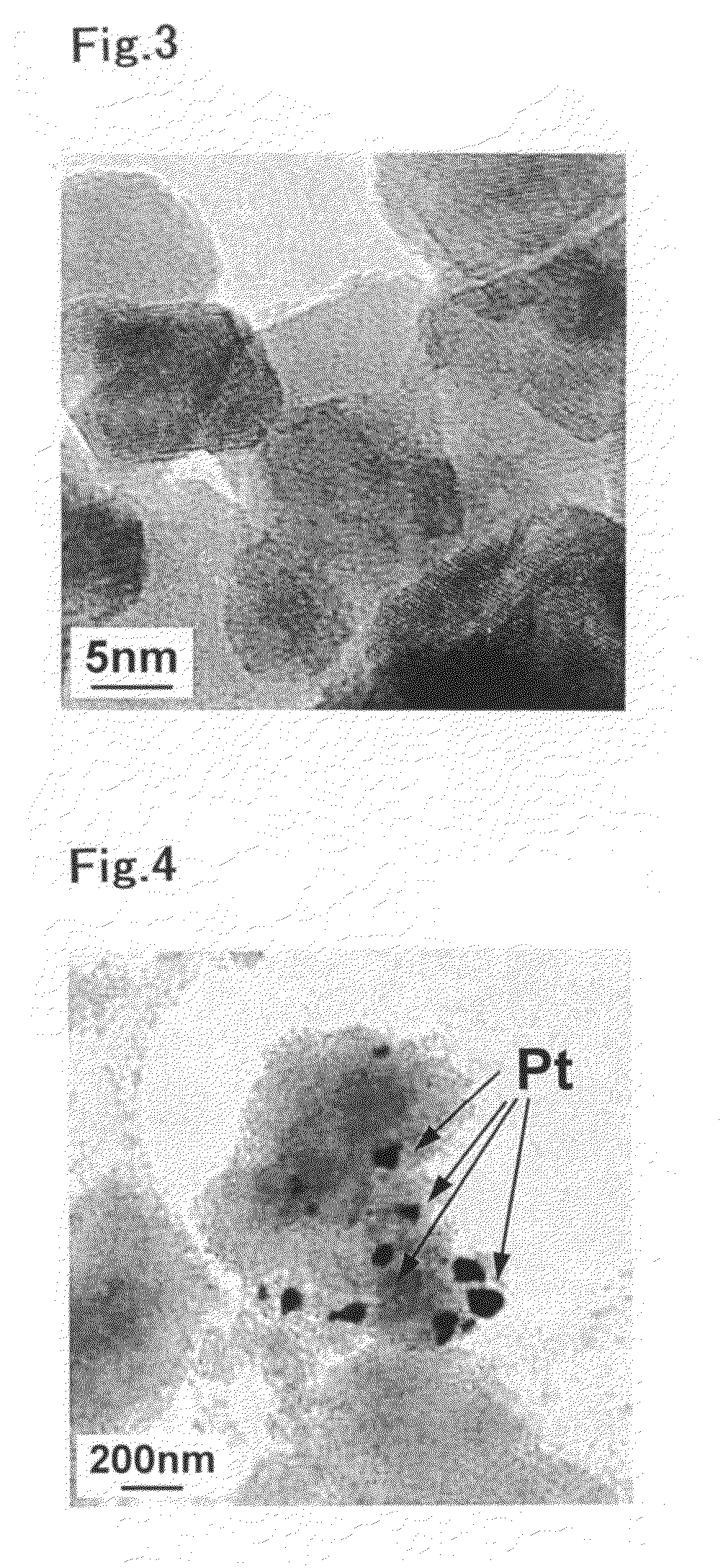

Catalyst for purification of exhaust gas, regeneration method for the catalyst, and apparatus and method for purification of exhaust gas using the catalyst

InactiveUS8105561B2Inhibiting lowering of catalytic activityPromote regenerationNitrogen compoundsInternal combustion piston enginesOxidation stateChemisorption

A catalyst for purification of exhaust gas in which a noble metal is supported on a metal-oxide support wherein, in a oxidation atmosphere, the noble metal exists on the surface of the support in high oxidation state, and the noble metal binds with a cation of the support via an oxygen atom on the surface of the support to form a surface oxide layer and, in a reduction atmosphere, the noble metal exists on the surface of the support in a metal state, and an amount of noble metal exposed at the surface of the support, measured by CO chemisorption, is 10% or more in atomic ratio to a whole amount of the noble metal supported on the support.

Owner:TOYOTA CENT RES & DEV LAB INC +1

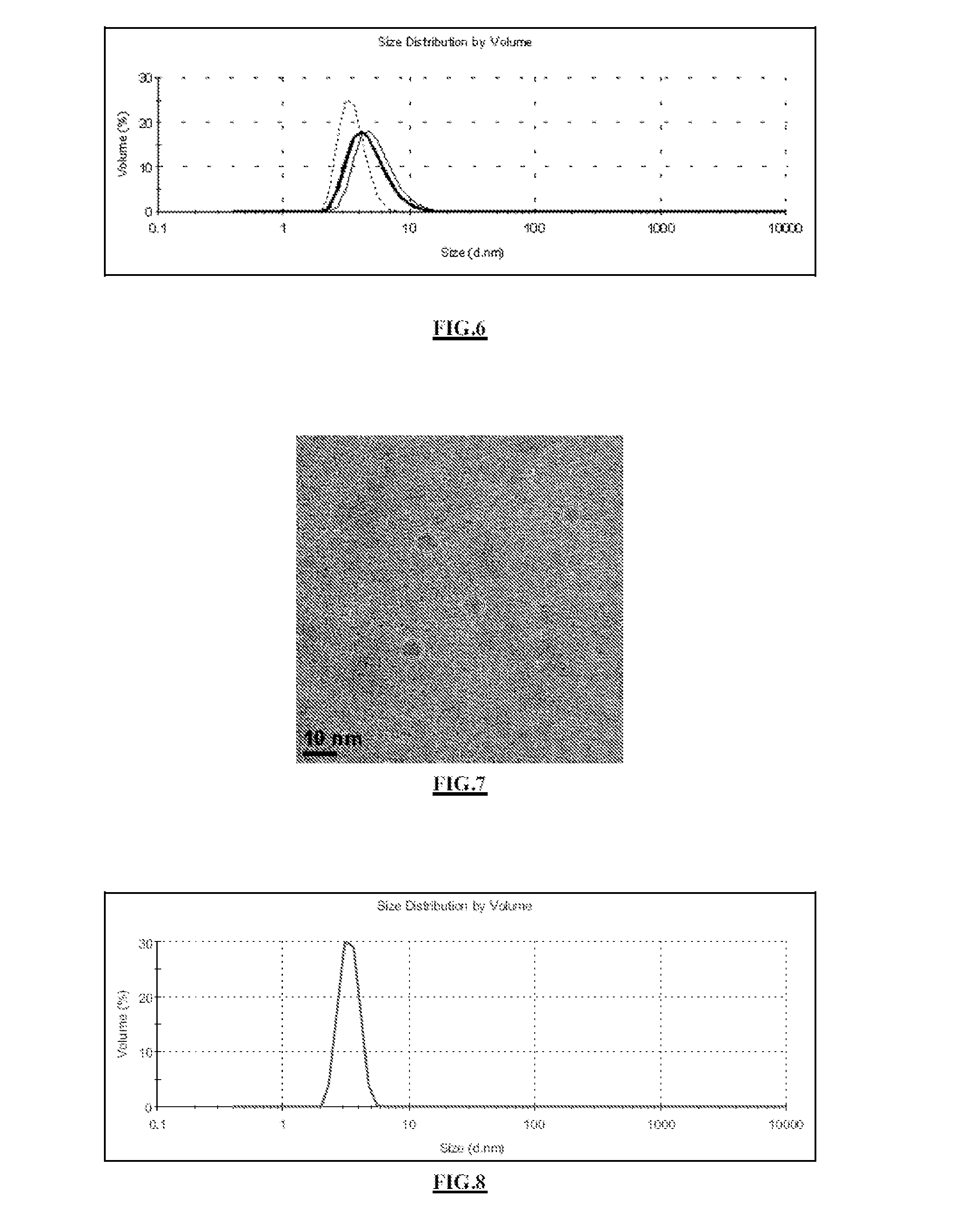

Ultrafine nanoparticles comprising a functionalized polyorganosiloxane matrix and including metal complexes; method for obtaining same and uses thereof in medical imaging and/or therapy

InactiveUS20130195766A1Increase loadPowder deliveryGeneral/multifunctional contrast agentsDiethylenetriaminepentaacetic acidHigh frequency

The invention relates to novel biocompatible hybrid nanoparticles of very small size, useful in particular for diagnostics and / or therapy.The purpose of the invention is to offer novel nanoparticles which are useful in particular as contrast agents in imaging (e.g. MRI) and / or in other diagnostic techniques and / or as therapeutic agents, which give better performance than the known nanoparticles of the same type and which combine both a small size (for example less than 20 nm) and a high loading with metals (e.g. rare earths), in particular so as to have, in imaging (e.g. MRI), strong intensification and a correct response (increased relaxivity) at high frequencies.Thus, the nanoparticles according to the invention, with diameter d1 between 1 and 20 nm, each comprise a polyorganosiloxane (POS) matrix including gadolinium cations optionally associated with doping cations; a chelating graft C1 DTPABA (diethylenetriaminepentaacetic acid bisanhydride) bound to the POS matrix by an —Si—C— covalent bond, and present in sufficient quantity to be able to complex all the gadolinium cations; and optionally another functionalizing graft Gf* bound to the POS matrix by an —Si—C— covalent bond (where Gf* can be derived from a hydrophilic compound (PEG); from a compound having an active ingredient PA1; from a targeting compound; from a luminescent compound (fluorescein).The method for the production of these nanoparticles and the applications thereof in imaging and in therapy also form part of the invention.

Owner:NANO H +2

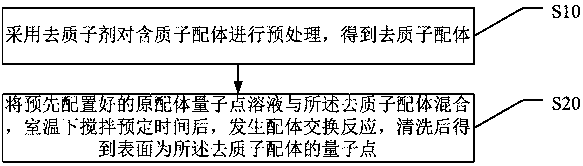

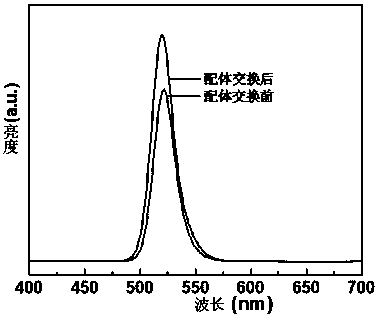

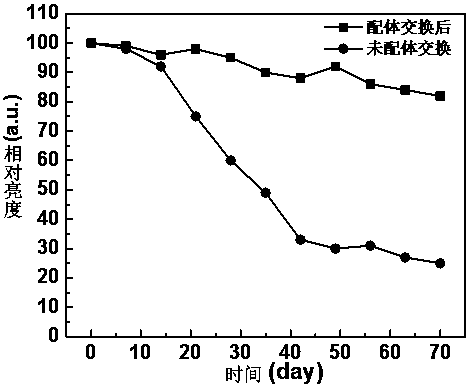

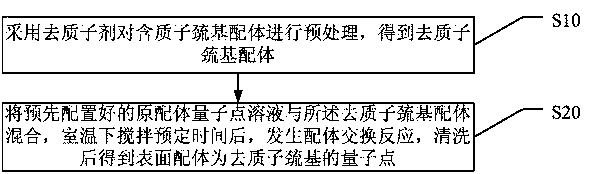

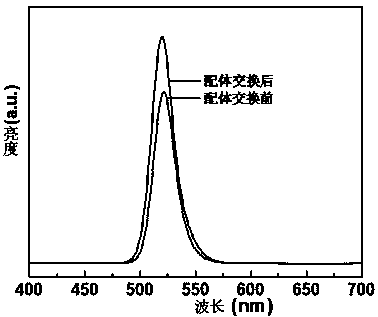

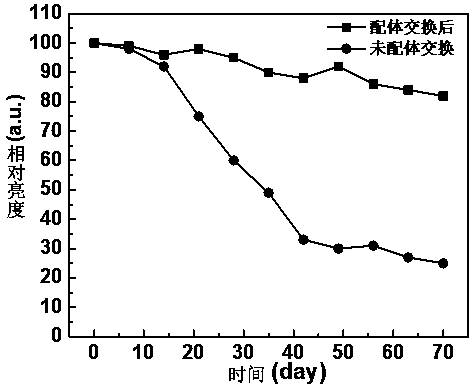

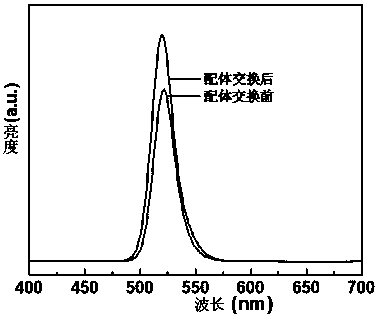

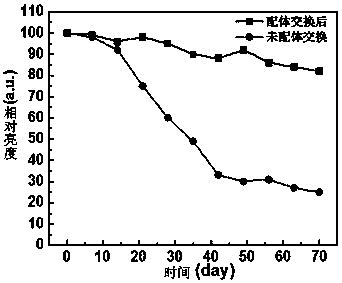

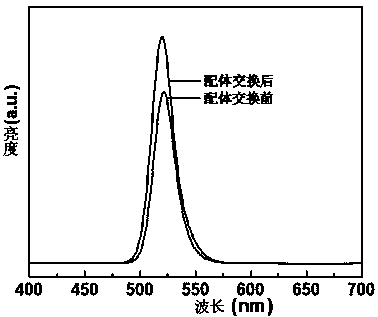

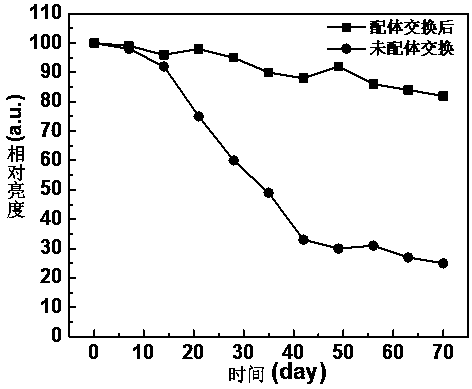

Quantum dot surface ligand exchange method

The invention discloses a quantum dot surface ligand exchange method, which comprises: pre-treating a proton-containing ligand by using a deprotonating agent to obtain a deprotonated ligand; mixing apre-prepared original ligand quantum dot solution and the deprotonated ligand; stirring for a predetermined time at a room temperature; and carrying out a ligand exchange reaction, and washing to obtain the quantum dot with the deprotonated ligand on the surface. According to the present invention, the quantum dot surface ligand exchange method has characteristics of rapid reaction and simple operation, the deprotonated ligand after the exchange is firmly combined with the cation on the surface of the quantum dot, and the exchanged quantum dot colloid solution has characteristics of strong stability, good solubility and high light-emitting efficiency.

Owner:TCL CORPORATION

Preparation method for tetra-alkyl ammonium hydroxide

InactiveCN105112934APrevent precipitationPromote precipitationCellsElectrolytic organic productionComing outElectrolysis

The invention belongs to the technical field of electrochemical synthesis and relates to a preparation method for tetra-alkyl ammonium hydroxide. A three-film four-chamber electrodialysis device is adopted, and tetra-alkyl ammonium salt serves as raw material to prepare the tetra-alkyl ammonium hydroxide. Firstly, a tetra-alkyl ammonium salt aqueous solution, pure water, anolyte and an acid solution are added to a salt chamber, a cathode chamber, an anode chamber and an acid chamber respectively, power is turned on, tetra-alkyl ammonium cations penetrate a first cation film to enter the anode chamber, anions penetrate an anion film to enter the acid chamber; the anolyte is electrolyzed to generate O2 and cations H+, and the H+ combine with the anions coming out of the salt chamber to generate anolyte after the H+ enter the acid chamber; and water molecules is electrolyzed at a negative plate to form H2 and anions OH-, and the anions OH- combine with the tetra-alkyl ammonium cations to form a tetra-alkyl ammonium hydroxide solution. The preparation method is simple in process, convenient to operate, scientific in principle, low in cost, environmentally friendly, and capable of being applied to large-scale industrial production easily.

Owner:QINGDAO RUNXING PHOTOELECTRIC MATERIAL

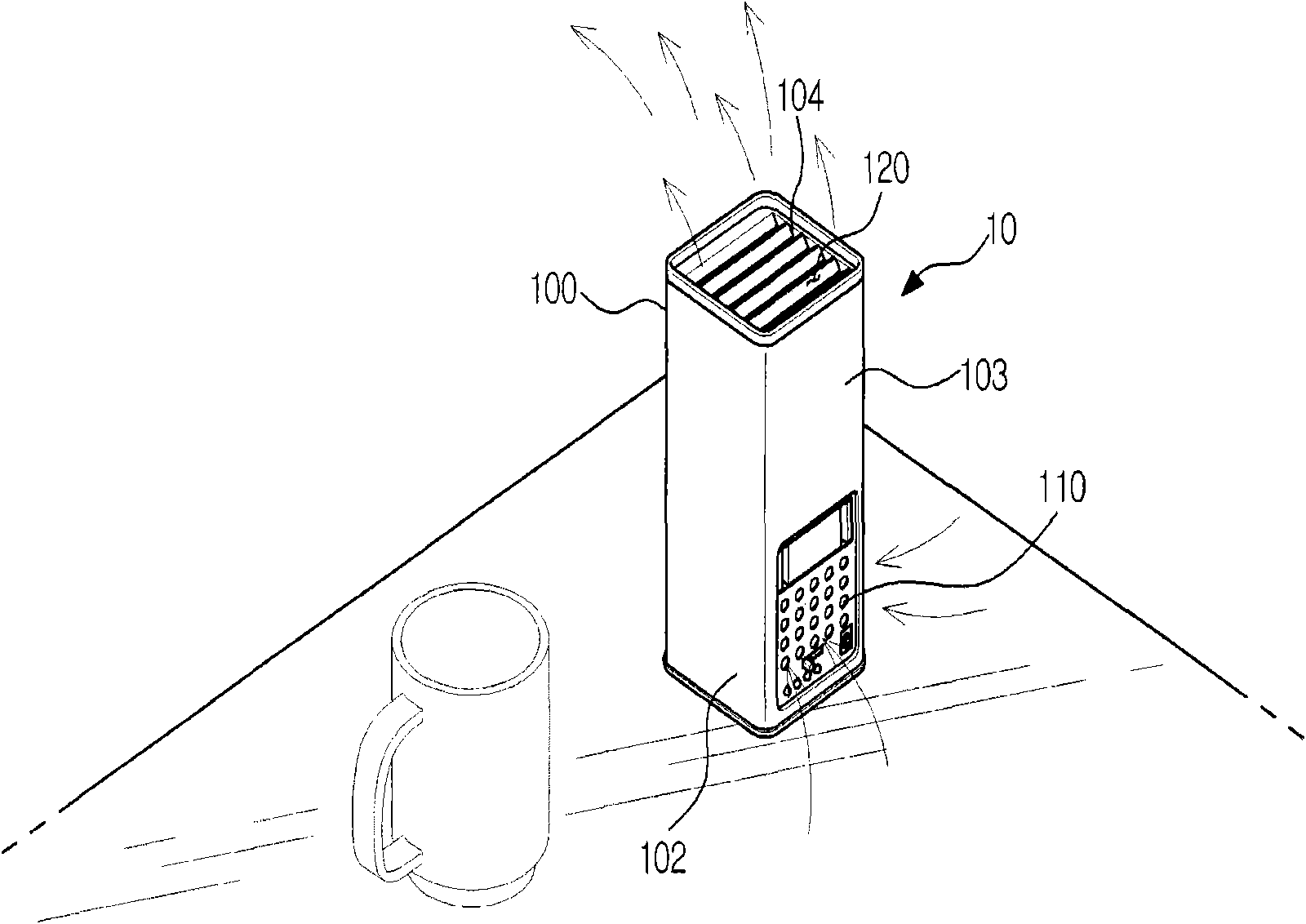

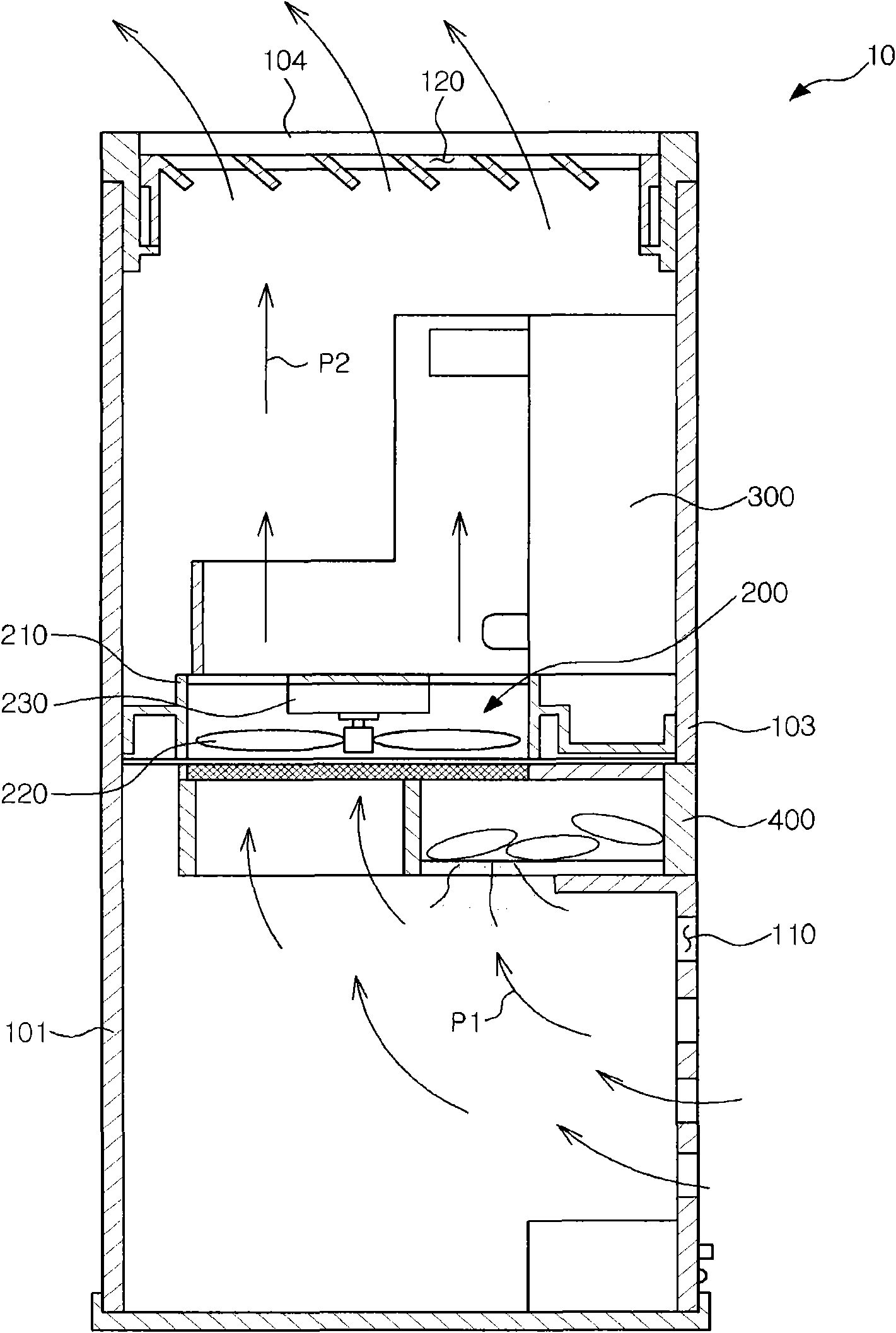

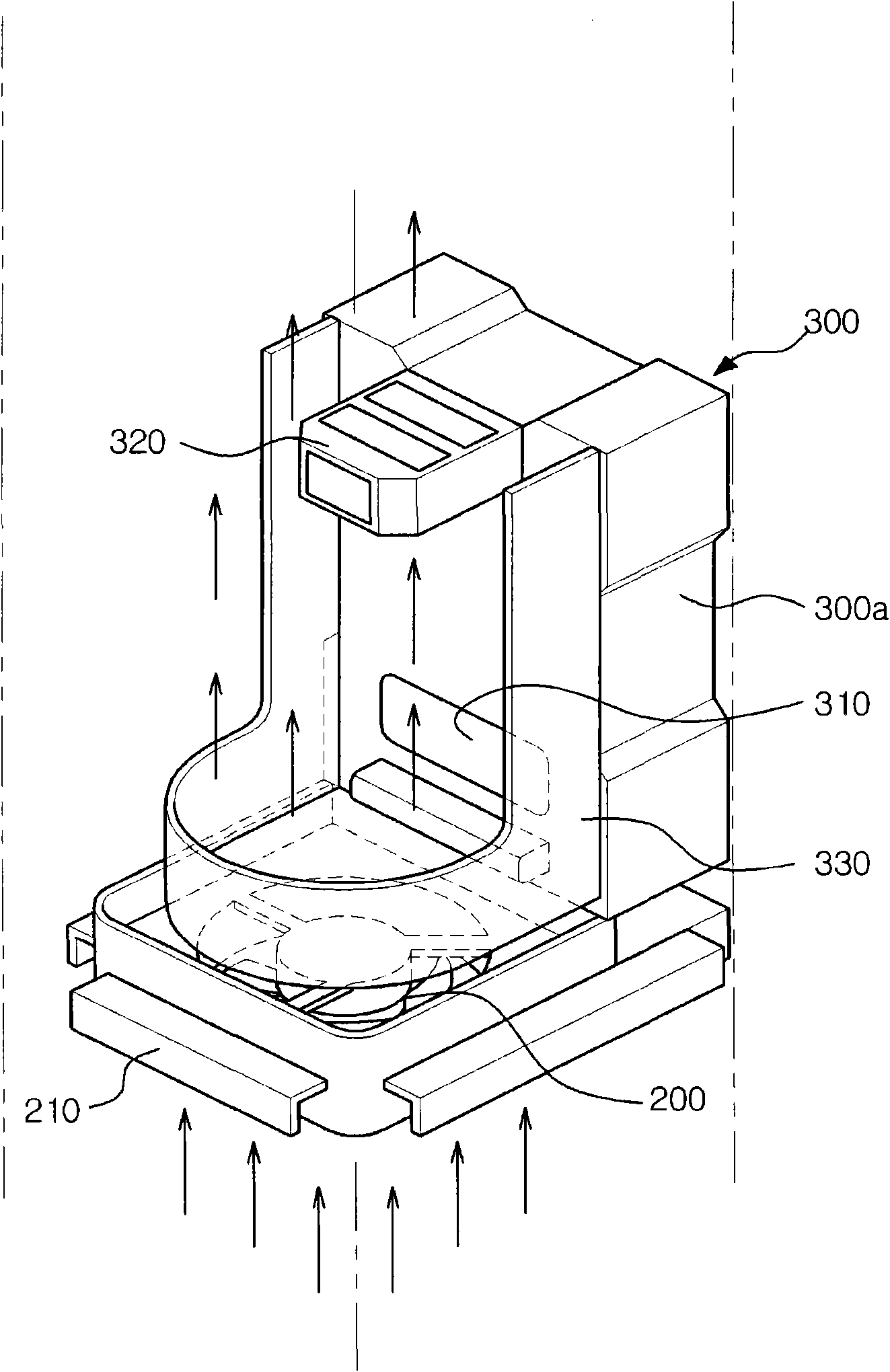

Air purifier

InactiveCN101623510AAvoid exposureEasy to replaceMechanical apparatusElectrical apparatusAir purifiersEngineering

The present invention provides an air purifier which comprises an ion generating unit, the ion generating unit comprises a first electrode for generating cation and a second electrode for generating electron to form neutral atom by combining with the cation. The air purifier also comprises: a main body having a suction mouth and an exhaust mouth; a ventilator for exhausting the sucked-air to the exhaust mouth; an exhaust passage formed between the ventilator and the exhaust mouth; the ion generating unit arranged on the exhaust passage comprises the first electrode for generating cation and the second electrode for generating electron to form neutral atom by combining with cation.

Owner:SAMSUNG ELECTRONICS CO LTD

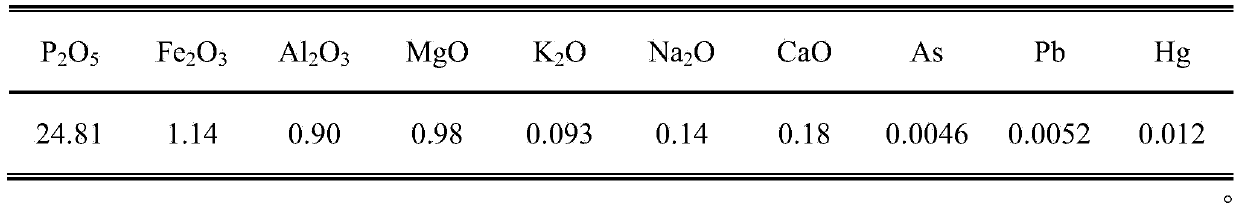

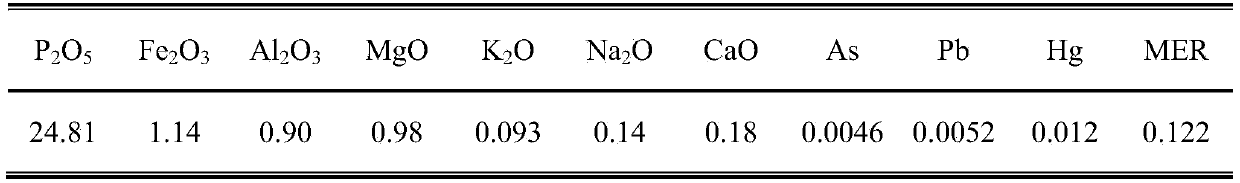

Wet process phosphoric acid purification technology of nonphosphate precipitation

ActiveCN105366654AMeet the concentrationWater soluble fertilizerPhosphorus compoundsChemical industryHigh concentration

The invention discloses a wet process phosphoric acid purification technology of nonphosphate precipitation and belongs to the field of phosphorus chemical industry. According to the wet process phosphoric acid purification technology of nonphosphate precipitation, an agent is combined with anions and cations in diluted phosphoric acid to generate an indissolvable double salt which is precipitated in a form of nonphosphate, so that a purpose of wet process phosphoric acid purification is achieved, thereby satisfying the demand of producing a high-concentration phosphate fertilizer, a water soluble fertilizer and an industrial phosphate product. The method can remove iron, magnesium, aluminum, arsenic, lead, sodium, potassium, sulfate radicals and the like stably in wet process phosphoric acid and has characteristics of being simple in reaction condition, short in a process flow, wide in an agent source, low in a treatment cost, high in a P2O5 recovery rate and the like, so that sesquioxide-removal, heavy metal removal and desulfuration by a one-step method are realized. The removal rates of iron, magnesium and aluminum in the treated wet process phosphoric acid separately reaches above 97%, 70% and 15%; arsenic and lead in diluted acid are less than 5 ppm; sodium (calculated by NaO) and potassium (calculated by K2O) are separately lower than 0.025% and 0.083%; sulfate radicals are lower than 0.16%; and the P2O5 recovery rate is higher than 98.5%.

Owner:YUNNAN PHOSPHATE CHEM GROUP CORP

Water treatment by dendrimer-enhanced filtration

Described herein are compositions and methods useful for the purification of aqueous fluids using dendritic macromolecules. The process involves using dendritic macromolecules (dendrimers) to bind to or chemically transform solutes, and a filtration step to produce fluid from which solutes have been removed or chemically transformed. Examples of dendrimers that may be used in the process include cation-binding dendrimers, anion-binding dendrimers, organic compound-binding dendrimers, redox-active dendrimers, biological compound-binding dendrimers, catalytic dendrimers, biocidal dendrimers, viral-binding dendrimers, multi-functional dendrimers, and combinations thereof. The process is readily scalable and provides many options for customization.

Owner:CALIFORNIA INST OF TECH

Polymer micelle complex including nucleic acid

It is an object of the present invention to provide a polyion complex used as a non-viral gene vector, which achieves sufficiently high gene expression efficiency to a target cell. The polyion complex of the present invention comprises a block copolymer formed by binding polyethylene glycol to polycation via a disulfide group and a nucleic acid.

Owner:THE UNIV OF TOKYO

Preparation method of quantum dots using deprotonated thiol as surface ligand

InactiveCN108977195AImprove bindingIncrease reaction rateNanoopticsLuminescent compositionsThiolReaction rate

The invention discloses a preparation method of quantum dots using deprotonated thiol as a surface ligand. The preparation method comprises: pre-treating a proton-containing thiol ligand by using a deprotonation agent to obtain a deprotonated thiol ligand; and mixing a pre-prepared original ligand quantum dot solution and the deprotonated thiol ligand, stirring for a predetermined time at a room temperature, carrying out a ligand exchange reaction, and washing to obtain the quantum dots using the deprotonated thiol as the surface ligand. According to the present invention, the reaction rate ofthe preparation method is rapid, the deprotonated thiol after the exchange is firmly combined with the cation on the surface of the quantum dot, and finally the obtained quantum dot using the deprotonated thiol as the surface ligand has characteristics of strong stability and high light-emitting efficiency.

Owner:TCL CORPORATION

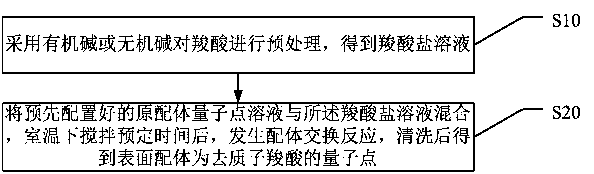

Preparation method of quantum dots using deprotonated carboxylic acid as surface ligand

InactiveCN108977194AImprove stabilityImprove luminous efficiencyMaterial nanotechnologyNanoopticsSolubilityReaction rate

The invention discloses a preparation method of quantum dots using deprotonated carboxylic acid as a surface ligand. The preparation method comprises: pre-treating carboxylic acid by using an organicalkali or an inorganic alkali to obtain a carboxylate solution; and mixing a pre-prepared original ligand quantum dot solution and the carboxylate solution, stirring for a predetermined time at a roomtemperature, carrying out a ligand exchange reaction, and washing to obtain the quantum dots using the deprotonated carboxylic acid as the surface ligand. According to the present invention, the reaction rate of the preparation method is rapid, the deprotonated carboxylic acid after the exchange is firmly combined with the cation on the surface of the quantum dot, and the finally obtained quantumdot colloid solution using the deprotonated carboxylic acid as the surface ligand has characteristics of strong stability, good solubility and high light-emitting efficiency.

Owner:TCL CORPORATION

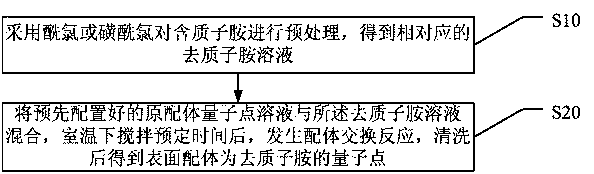

Preparation method of quantum dots using deprotonated amine as surface ligand

InactiveCN108977192AImprove bindingImprove stabilityMaterial nanotechnologyNanoopticsSulfonyl chlorideReaction rate

The invention discloses a preparation method of quantum dots using deprotonated amine as a surface ligand. The preparation method comprises: pre-treating a proton-containing amine by using acyl chloride or sulfonyl chloride to obtain a corresponding deprotonated amine solution; and mixing a pre-prepared original ligand quantum dot solution and the deprotonated amine solution, stirring for a predetermined time at a room temperature, carrying out a ligand exchange reaction, and washing to obtain the quantum dots using the deprotonated amine as the surface ligand. According to the present invention, the reaction rate of the preparation method is rapid, the deprotonated amine after the exchange is firmly combined with the cation on the surface of the quantum dot, and finally the obtained quantum dot colloid solution using the deprotonated amine as the surface ligand has characteristics of strong stability and high light-emitting efficiency.

Owner:TCL CORPORATION

Method for preparing polyelectrolyte composite nanofiltration membrane by using freeze drying technology

ActiveCN109157982AIncrease mass transfer rateImprove structural stabilityReverse osmosisWater/sewage treatment bu osmosis/dialysisFreeze-dryingSolvent

The invention discloses a method for preparing a polyelectrolyte composite nanofiltration membrane by using a freeze drying technology, and belongs to the field of membrane separation. The method comprises the following steps: pretreating porous basement membranes, and removing surface impurities; dissolving polycations and polyanions into a solvent respectively to form respective solution; carrying out static assembling on the pretreated basement membranes in the polycation solution, then washing with deionized water, removing the polycations which are not adsorbed on the surfaces of the basement membranes, and naturally volatilizing the solvent at room temperature; combining the polyanions with negative charges with the polycations with positive charges by using a dynamic assembling form, and assembling the polyanions and the polycations onto the surface of the obtained membrane through the effect of ionic bonds; putting the obtained assembled membrane into a freeze drying machine, and completely carrying out ice crystallization on the solvent in a polyelectrolyte composite membrane in the condition of low temperature, and then carrying out sublimation drying to prepare the polyelectrolyte composite nanofiltration membrane which is used for removal of water system small molecular substances and has good separation and stability.

Owner:BEIJING UNIV OF TECH

Electrolytic solution, preparation method thereof, secondary battery comprising electrolyte, and electric device

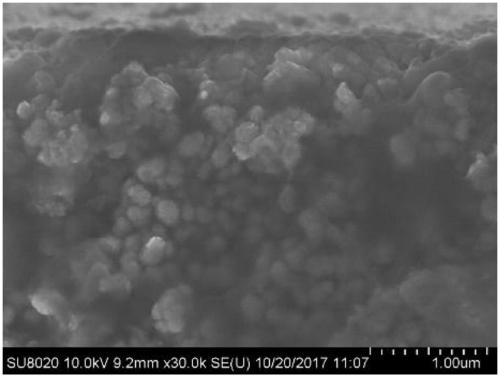

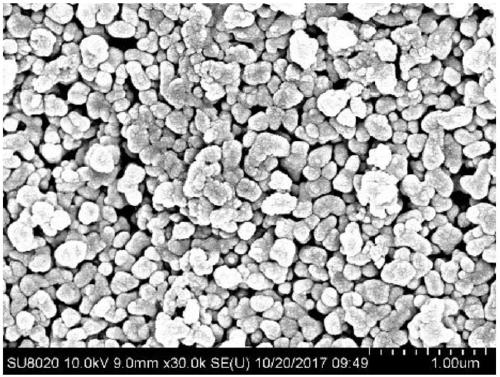

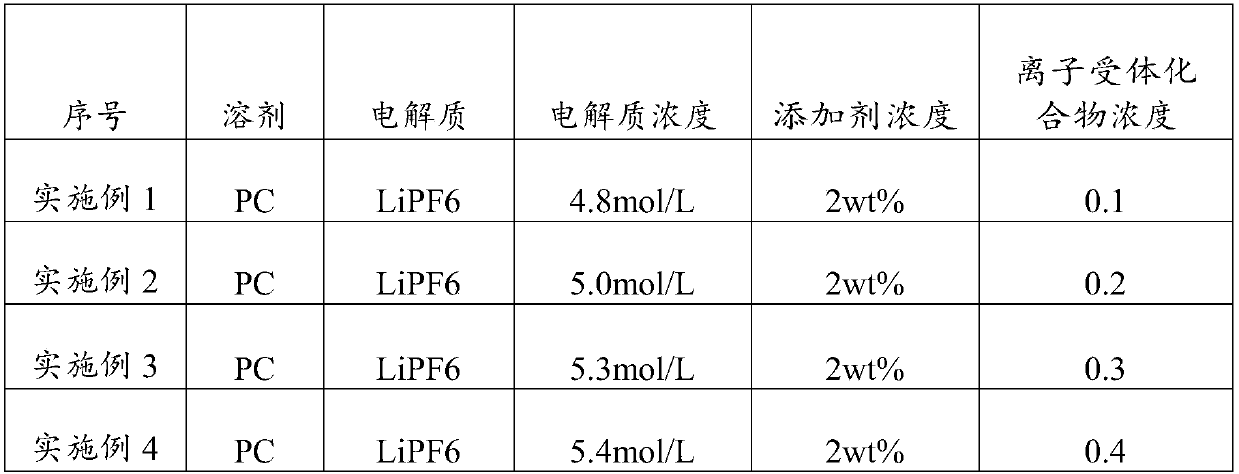

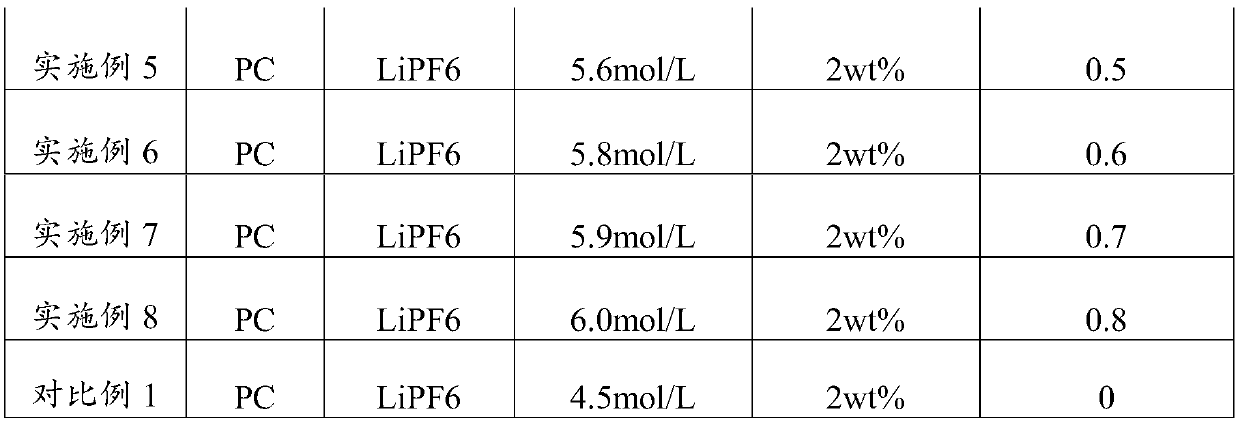

InactiveCN109524716AImprove solubilityIncrease concentrationSecondary cellsOrganic electrolytesHigh concentrationPhysical chemistry

The invention provides an electrolytic solution, a preparation method thereof, a secondary battery comprising the electrolytic solution, and an electric device, and relates to the field of batteries.The electrolytic solution is prepared from a solvent, an electrolyte, an additive and an ion receptor compound; the ion receptor compound comprises an anion receptor compound for binding to an anion in the electrolyte, and / or a cation receptor compound for binding to a cation in the electrolyte. With the electrolytic solution, the technical problem of requiring a specific solvent in the preparation of a high-concentration electrolytic solution in the prior art can be alleviated, and the purpose of increasing the concentration of the electrolytic solution without changing the solvent composition of the electrolytic solution can be achieved.

Owner:SHENZHEN INST OF ADVANCED TECH

Compositions and methods to improve oral absorption of antimicrobial agents

InactiveCN1441668AImprove stabilityAntibacterial agentsOrganic active ingredientsMicrobial agentBiopolymer

The present invention provides compositions and methods for increasing absorption of antibacterial agents, particularly third generation cephalosporin antibacterial agents, in oral dosage solid and / or suspension forms. Specifically, the composition is comprised of a biopolymer that is preferably swellable and / or mucoadhesive, an antimicrobial agent, and a cationic binding agent contained within the biopolymer such that the binding agent is ionically bound or complexed to at least one member selected from the group consisting of the biopolymer and the antimicrobial agent.

Owner:CUBIST PHARMA INC +2

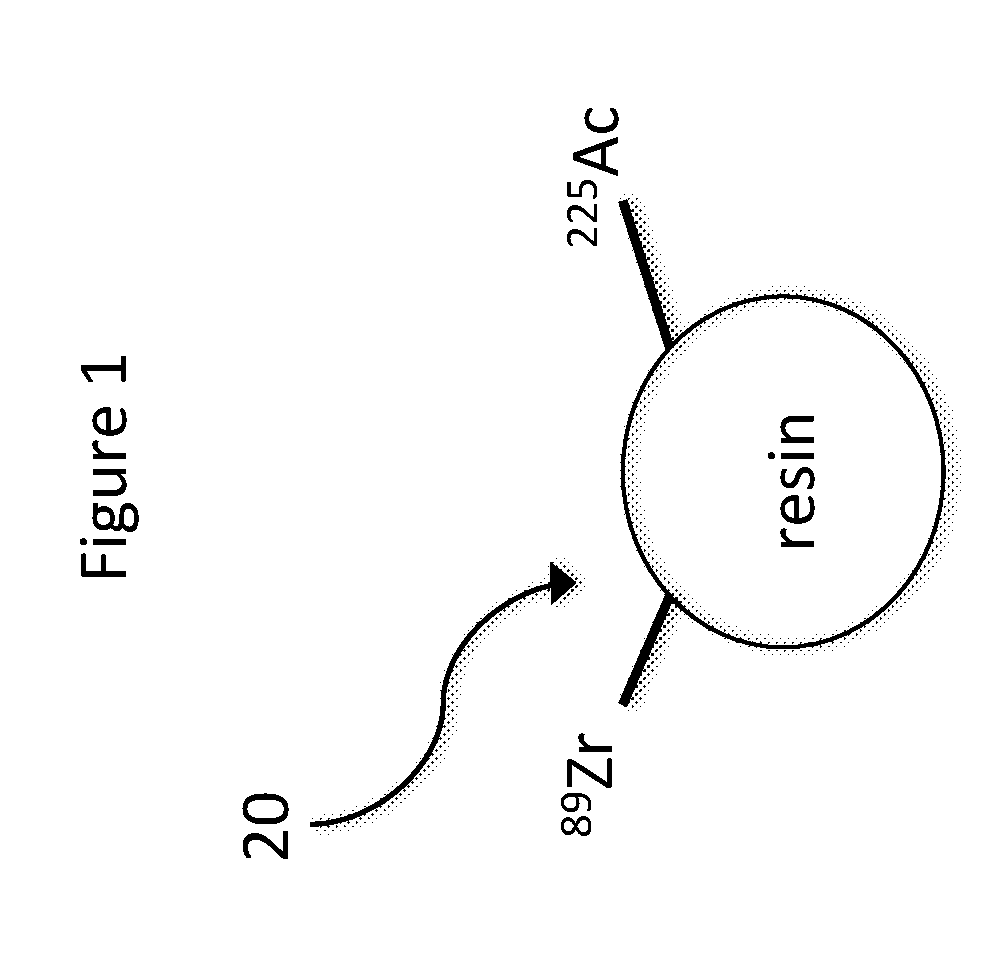

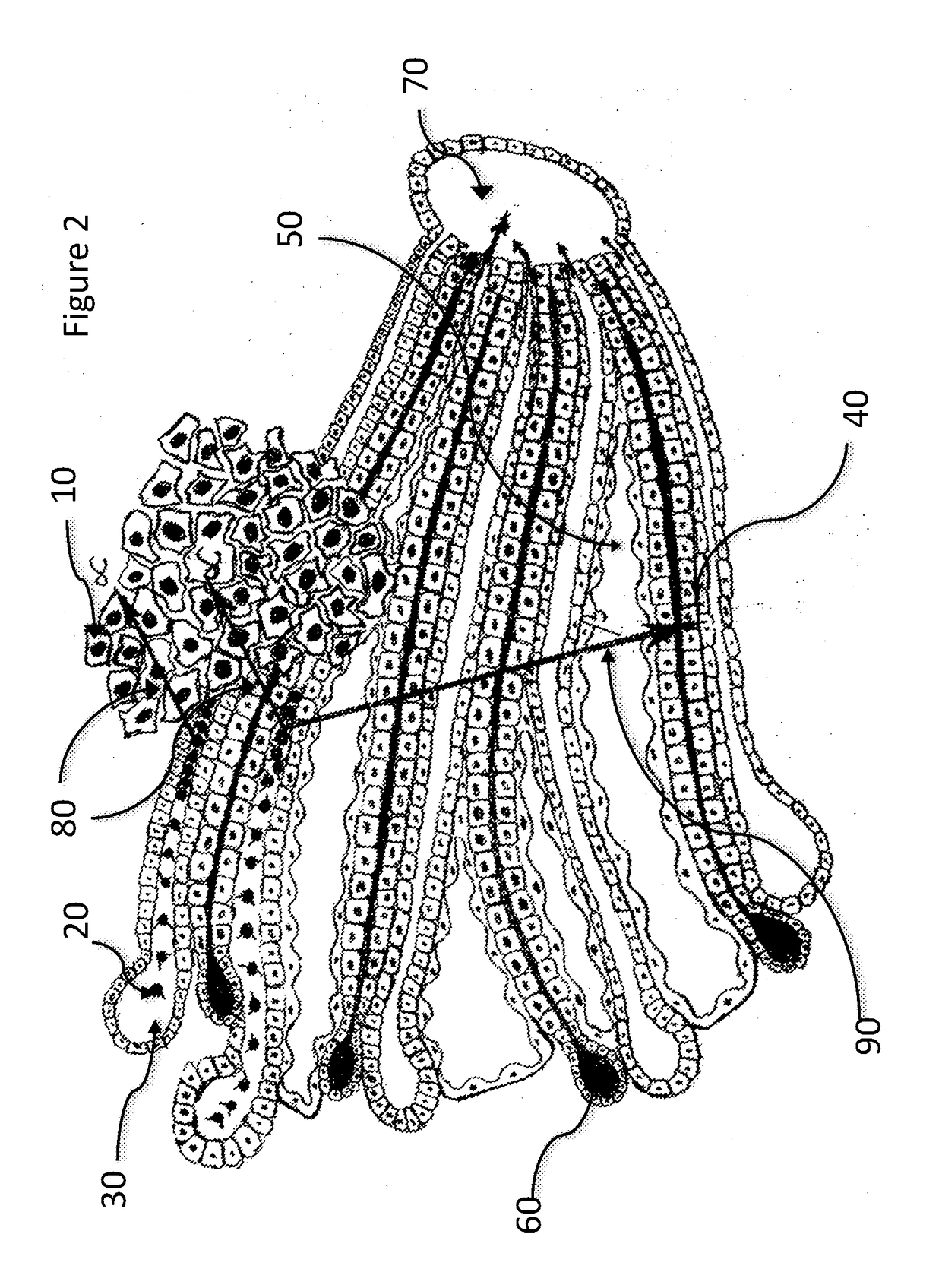

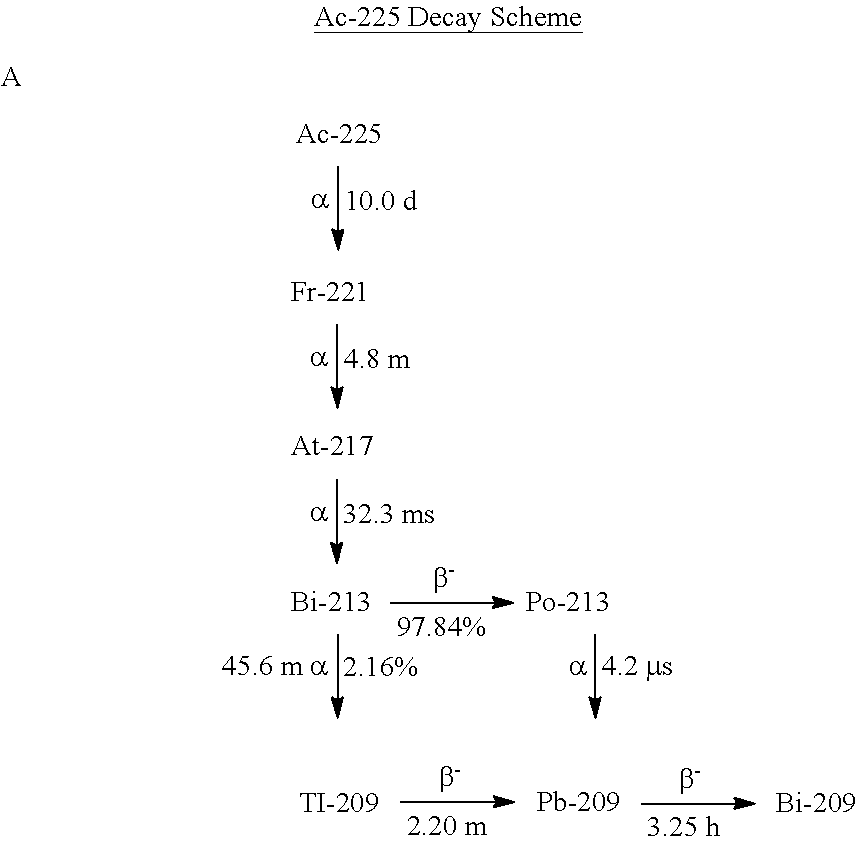

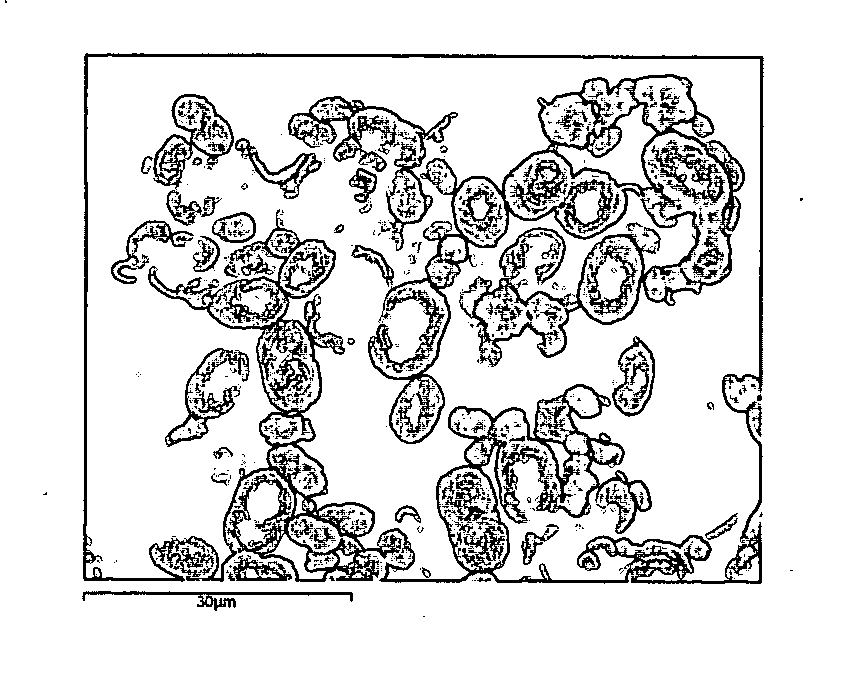

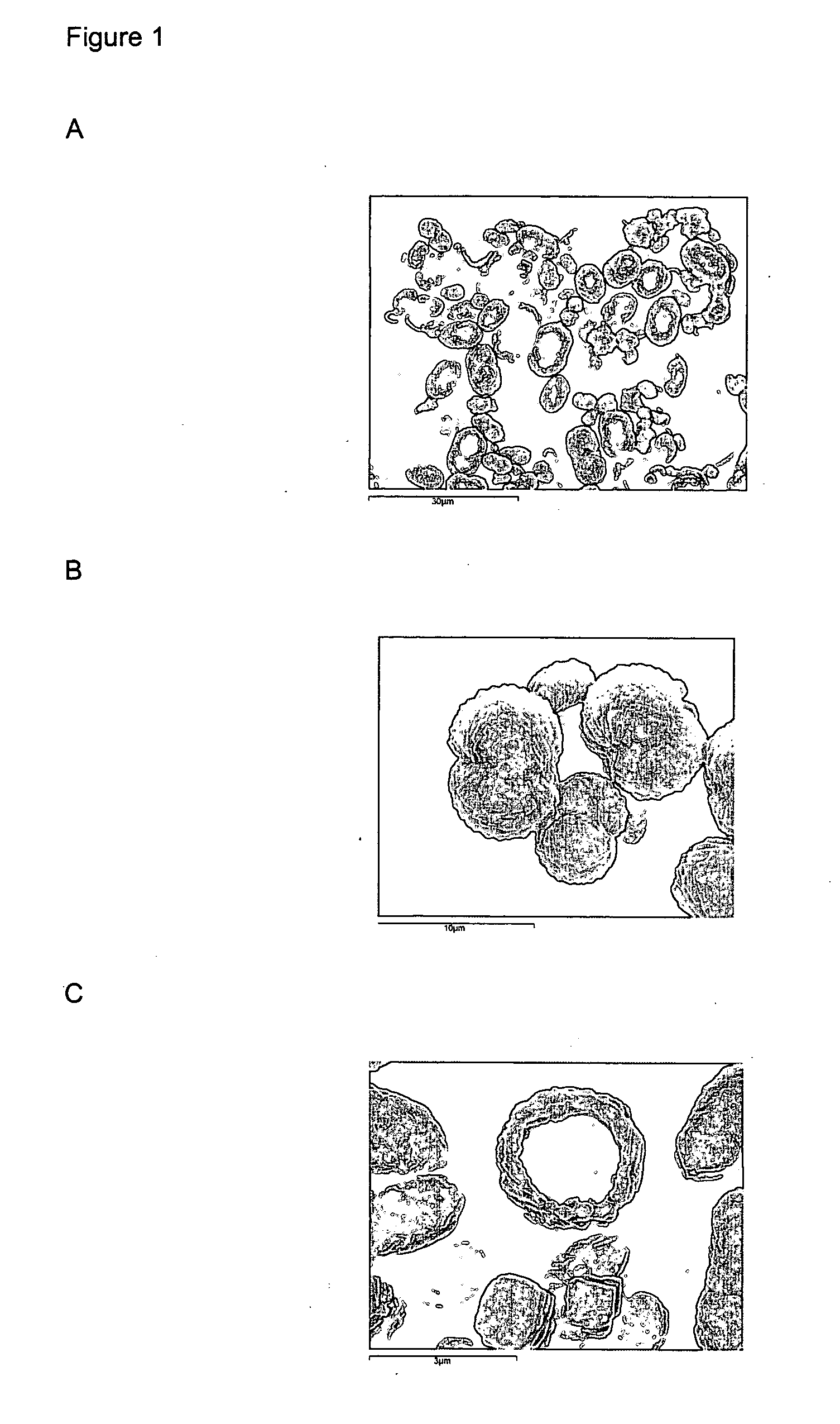

Method, Apparatus, and System for Radiation Therapy

A device and method for radioembolization in the treatment of cancer cells in the body. In preferred embodiments, a radiomicrosphere is formed from a resin where an alpha emitting isotope is used for tumoricidal purposes. As the alpha emitter decays, daughters of the alpha decay are captured by the resin. In accordance with the preferred embodiments, the resin is polyfunctional where the resin has at least three different types of functional groups for cation binding. In preferred embodiments, the three functional groups bonded to the resin include a carboxylic acid group, a diphosphonic acid group, and a sulfonic acid group. In further embodiments, the device comprises at least two isotopes; wherein a first isotope is for therapeutic purposes and a second isotope is for dosimetric purposes. The second isotope is a positron emitter for PET based dosimetry. In preferred embodiments, a post-treatment radiation absorbed dose is determined using the present invention, allowing both treatment and treatment efficacy to be provided to a cancer patient.

Owner:SIRTEX MEDICAL INC

Method of growing crystals

A composition is provided comprising a substance of interest encapsulated by a continuous layer of a plurality of salt crystals which layer is impermeable to the substance of interest. Also provided is a method of producing a continuous layer of a plurality of salt crystals, the salt comprising a cation and an anion, which method comprises (i) providing a substrate which comprises a plurality of negatively charged binding sites for the cation and / or a plurality of positively charged binding sites for the anion, and (ii) contacting the substrate with a solution of the salt under conditions which cause nucleation of salt crystals comprising the cation and the anion at a plurality of said binding sites, the plurality of charged binding sites being present on the surface of the substrate at a sufficient density so that the resulting plurality of salt crystals form a continuous layer.

Owner:CONOPCO INC D B A UNILEVER

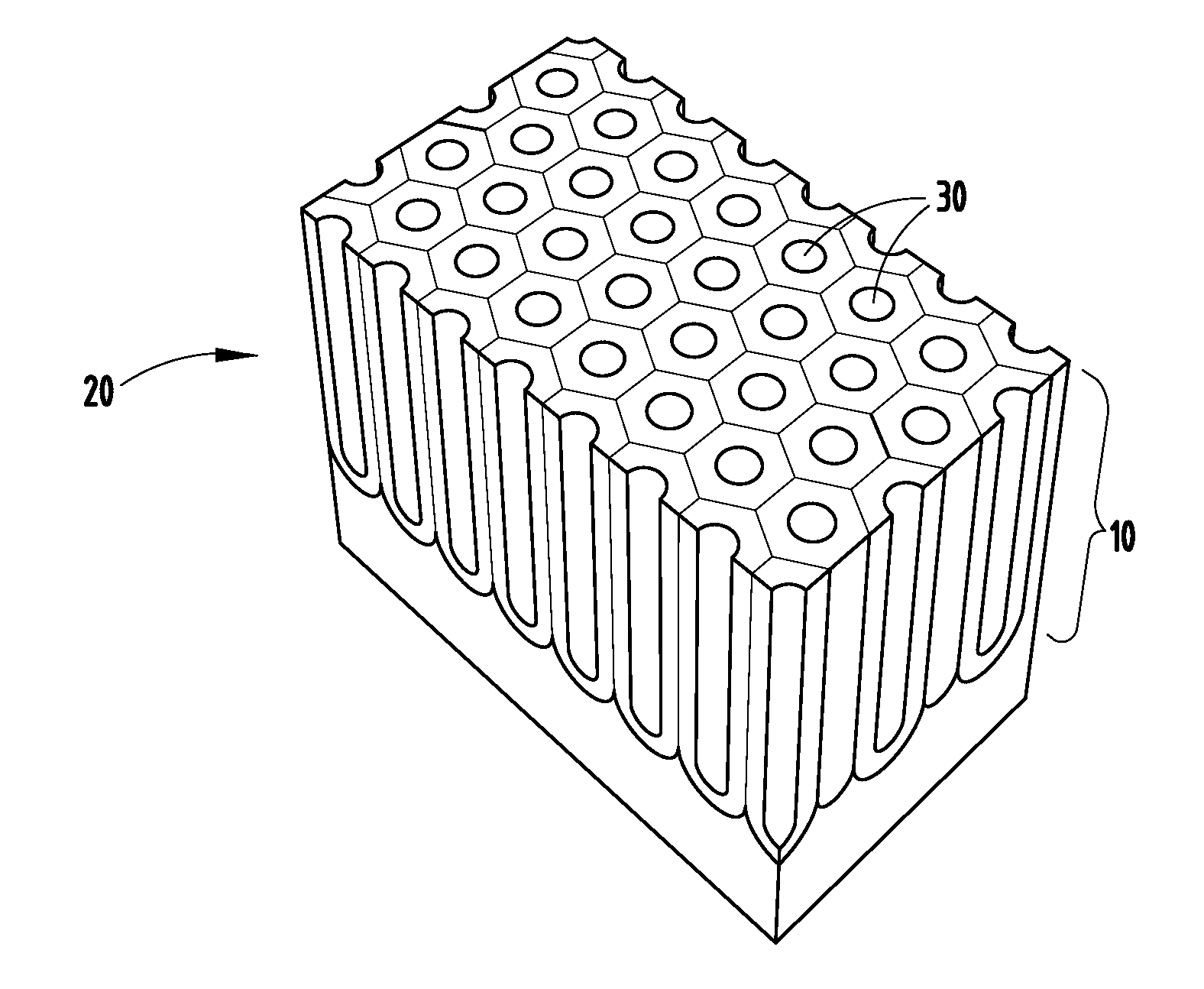

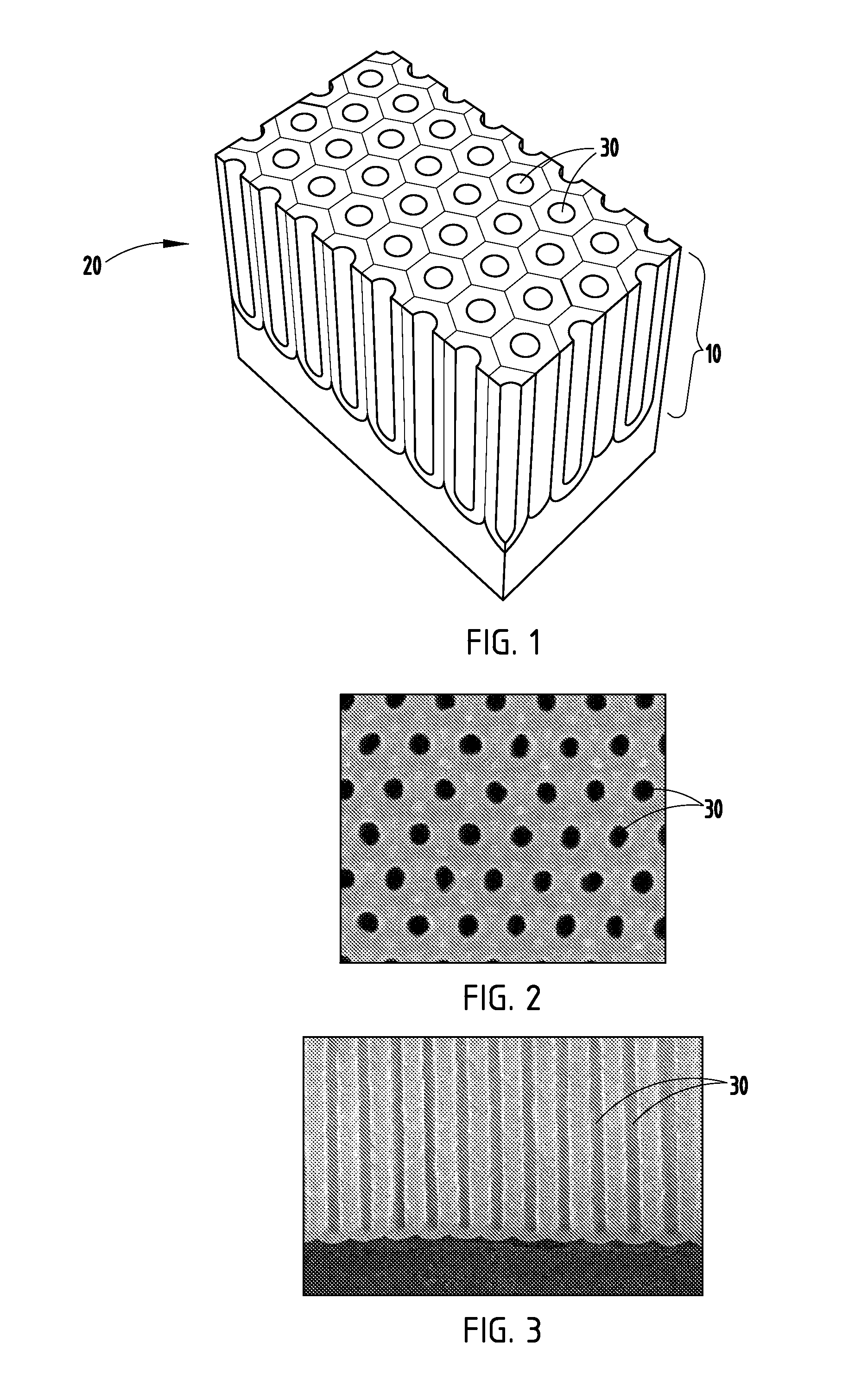

Sealed anodized aluminum components and process for their manufacture

InactiveUS20120088033A1Less equipmentLow costAnodisationPretreated surfacesProduction rateWater insoluble

A more efficient process of sealing an anodized aluminum article, which can facilitate higher production rates than conventional sealing techniques, includes steps of providing an article comprised of aluminum or an aluminum alloy that has been anodized, treating the oxide layer with a solution containing an anion capable of combining with a cation to form a water-insoluble precipitate, and contacting the treated oxide layer with a second solution containing a cation which combines with the anion to form a water-insoluble precipitate. In certain embodiments, the oxide layer can be treated with a dye to provide a sealed anodized aluminum article exhibiting enhanced dye retention.

Owner:SHEEHY MICHAEL

Compositions and methods to improve oral absorption of antimicrobial agents

InactiveCN100358579CImprove stabilityAntibacterial agentsOrganic active ingredientsBiopolymerMicrobial agent

The present invention provides compositions and methods for increasing absorption of antibacterial agents, particularly third generation cephalosporin antibacterial agents, in oral dosage solid and / or suspension forms. Specifically, the composition is comprised of a biopolymer that is preferably swellable and / or mucoadhesive, an antimicrobial agent, and a cationic binding agent contained within the biopolymer such that the binding agent is ionically bound or complexed to at least one member selected from the group consisting of the biopolymer and the antimicrobial agent.

Owner:CUBIST PHARMA INC +2

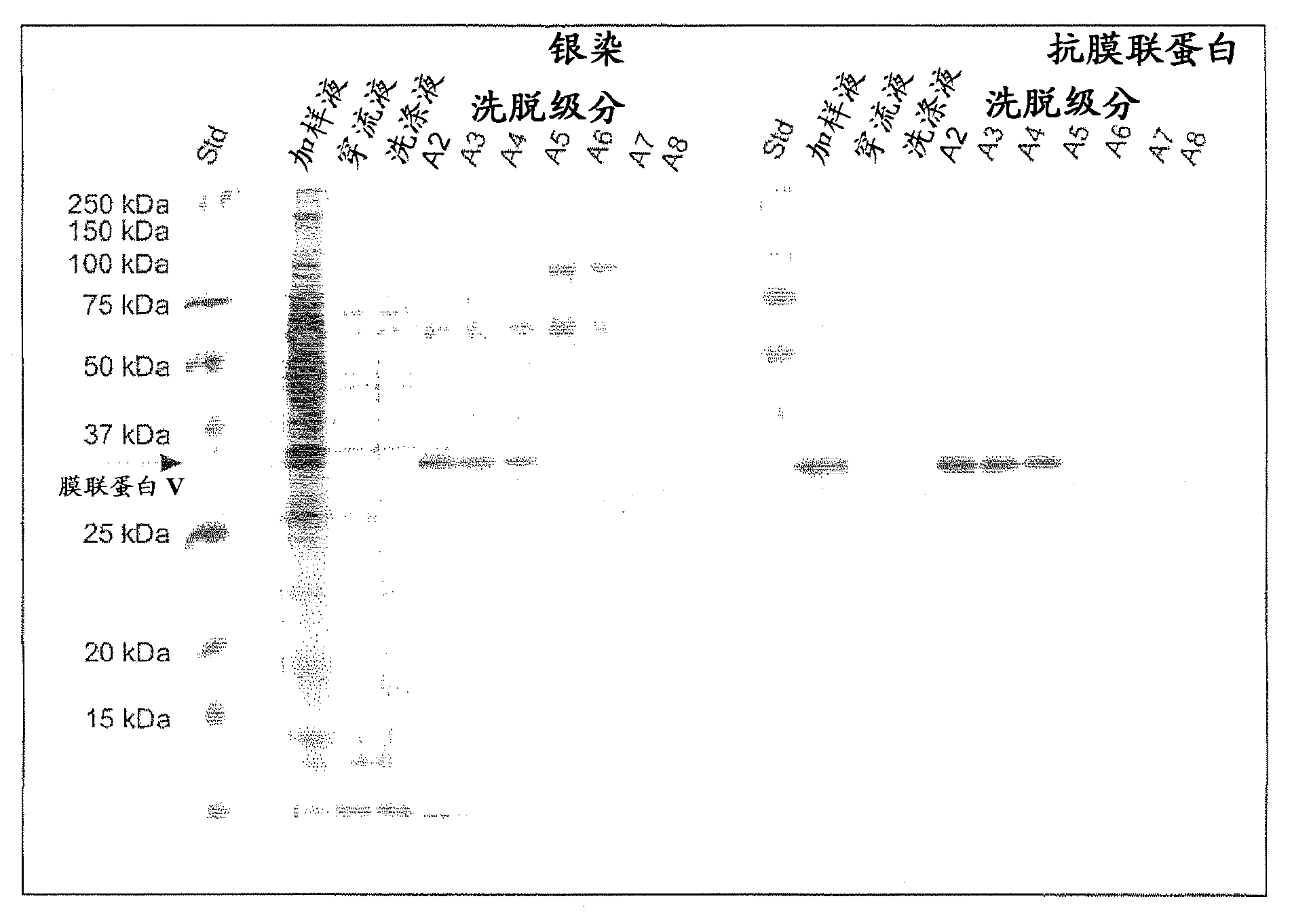

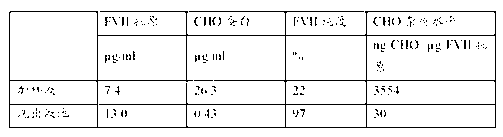

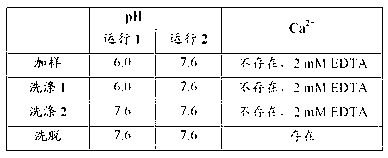

Purification method for divalent cation binding proteins on anion exchange resin

The present invention relates to a method for the purification of divalent cation binding proteins with high purity on an anion exchange resin material, to divalent cation binding proteins obtainable by said method, and to a kit comprising means for carrying out said method.

Owner:BAXALTA INC +1

Protein purification by anion exchange chromatography

ActiveUS20140302591A1Improve conductivityReduce conductivityPeptide preparation methodsBlood disorderAnion-exchange chromatographyTwo step

The present invention relates to a two-step method for the purification of divalent cation binding proteins with high yield and high purity on anion exchange resin materials, to divalent cation binding proteins obtainable by said method, and to a kit comprising means for carrying out said method.

Owner:TAKEDA PHARMA CO LTD

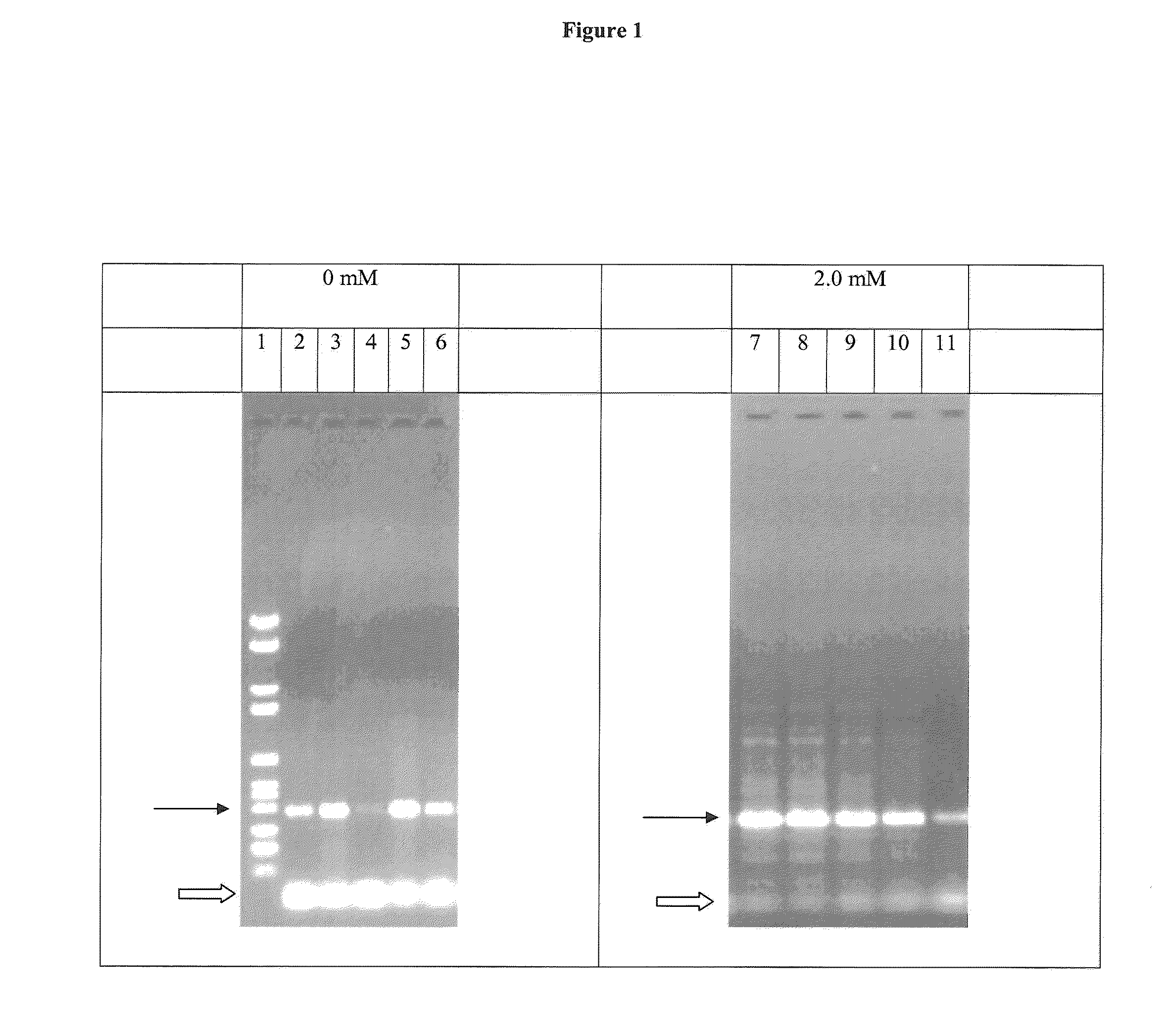

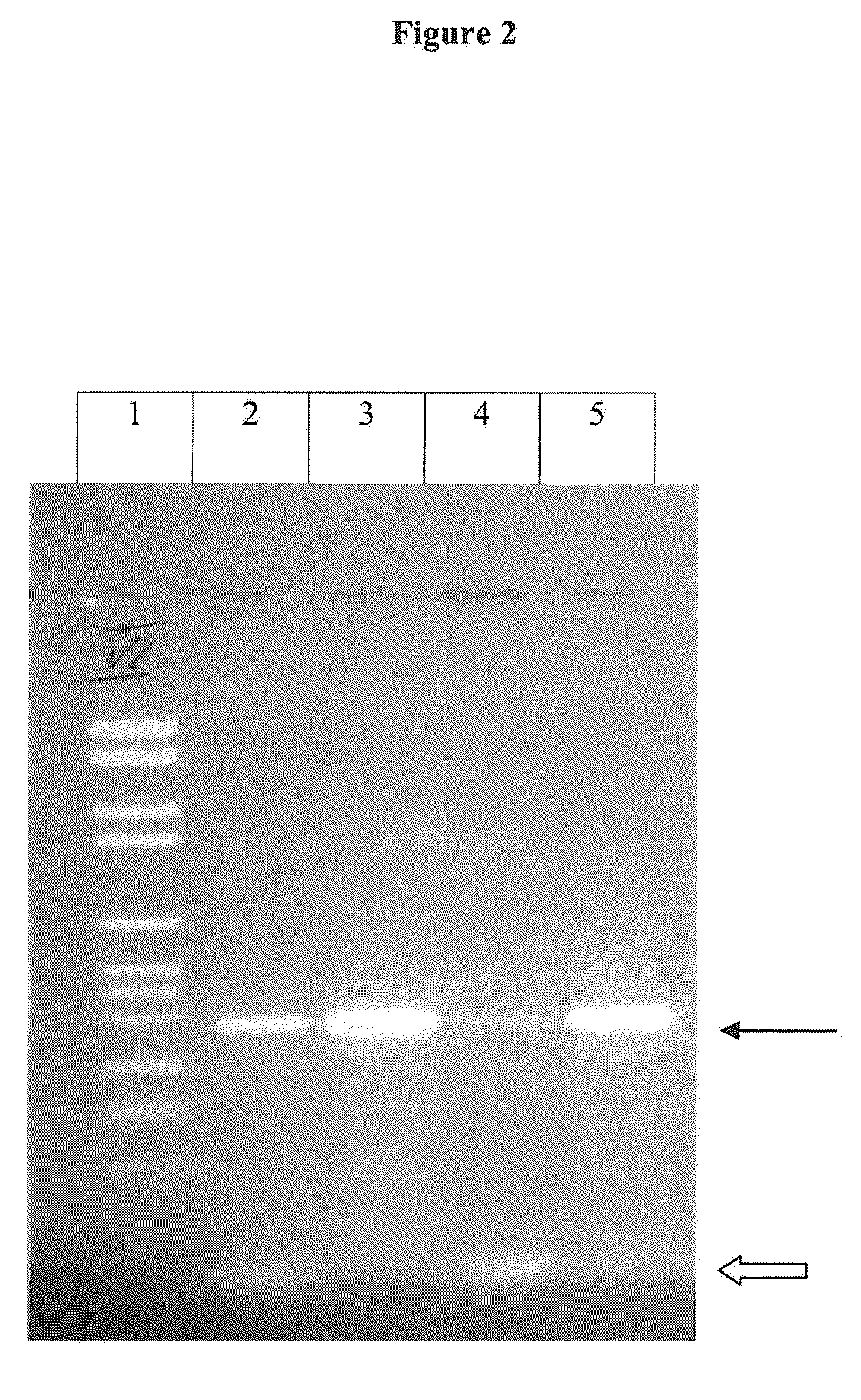

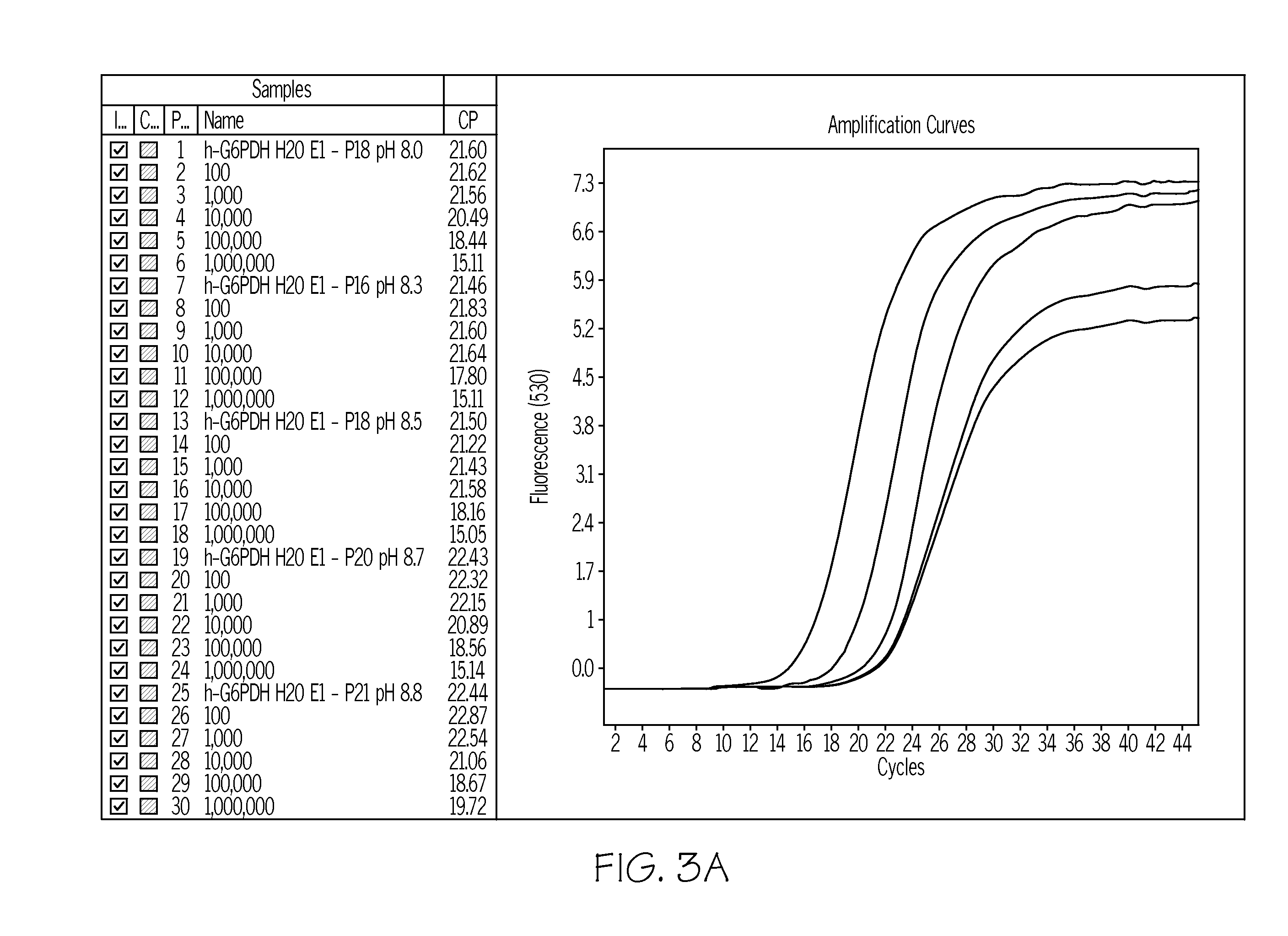

PCR hot start by magnesium sequestration

InactiveUS20100285535A1Peptide/protein ingredientsMicrobiological testing/measurementCation bindingHot start

The present invention is directed to a synthetic peptide having a length of not more than 30 amino acids comprising a divalent cation binding site. Such a peptide according to the present invention is part of a composition for nucleic acid amplification and provides for a so-called hot start effect.

Owner:ROCHE DIAGNOSTICS OPERATIONS INC

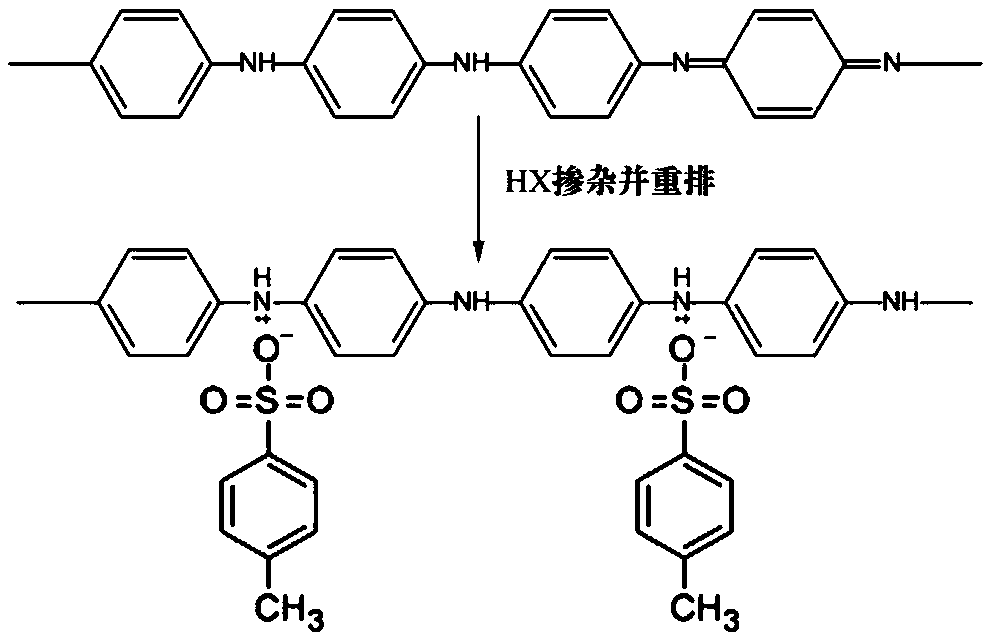

Orientated rod-shaped-structure polyaniline film and preparation method therefor

The invention relates to an orientated rod-shaped-structure polyaniline film and a preparation method therefor. The preparation method comprises the steps of preparing an electrolyte from aniline andprotonic acid, and then, carrying out deposition by employing an electrochemical polymerization method, thereby preparing the orientated rod-shaped-structure polyaniline film, wherein the protonic acid is p-toluenesulfonic acid, naphthalene sulfonic acid, salicylic acid or dodecylbenzene sulfonic acid. The prepared orientated rod-shaped-structure polyaniline film is mainly prepared from porous cross-linked polyaniline and rod-shaped polyanilines distributed on the surface of the porous cross-linked polyaniline, and the porous cross-linked polyaniline and the rod-shaped polyanilines are separately formed through cross-linking and piling stretched polyaniline molecular chains; nitrogen atoms, connected with quinone rings, in the stretched polyaniline molecular chains are bonded to cations ofthe protonic acid to form -NH<+=>, and anions of the protonic acid are attached to the -NH<+=> in the form of an ionic bond; and all the rod-shaped polyanilines are orientated along the same direction and are of non-equidistant arrangement along a direction of orientation, and holes are distributed in the rod-shaped polyanilines. The preparation method disclosed by the invention is simple, and the prepared orientated rod-shaped-structure polyaniline film is excellent in electrochromic performance.

Owner:DONGHUA UNIV

Polyamide with sulfonic acid group

InactiveCN104610542AImprove hydrophilicityImprove firmnessArtifical filament manufactureMonocomponent polyamides artificial filamentFiberPolymer science

The invention relates to a polyamide with a sulfonic acid group and a preparation method of the polyamide, and belongs to the field of high polymer material preparation. The polyamide with the sulfonic acid group is prepared by introducing a sulfonic acid group in the polyamide. The polyamide with the sulfonic acid group is characterized in that a monomer with the sulfonic acid group, a polyamide monomer, a catalyst and additives are mixed, a melt polymerization reaction is carried out, and the sulfonic acid group is introduced in the macromolecular structure of the polyamide, so that a polyamide chain is bonded with the lateral group of the sulfonic acid group, thus improving the cation binding performance and the hydrophilcity of the polymer material. The polyamide can be prepared into resin particles for spinning fibres and processing plastic products.

Owner:YIWU HUADING NYLON

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com