Orientated rod-shaped-structure polyaniline film and preparation method therefor

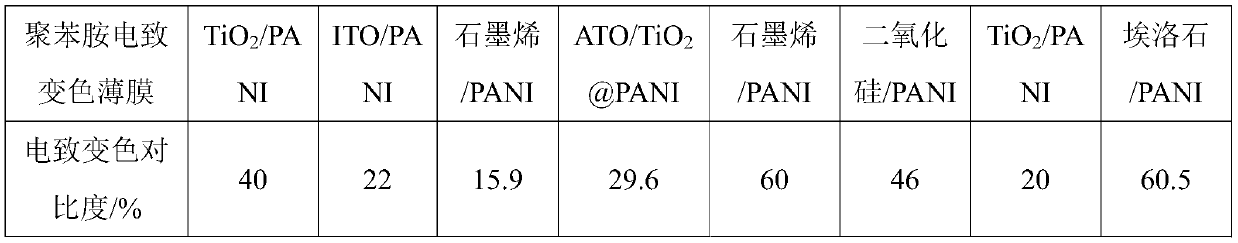

A technology of polyaniline film and rod-like structure, which is applied in the field of polyaniline film with oriented rod-like structure and its preparation, can solve the problems that the electrochromic performance needs to be further improved, the preparation process of polyaniline electrochromic film is complicated, etc., and achieve cycle stability Good performance, rich variety of discoloration, high electrochromic contrast

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

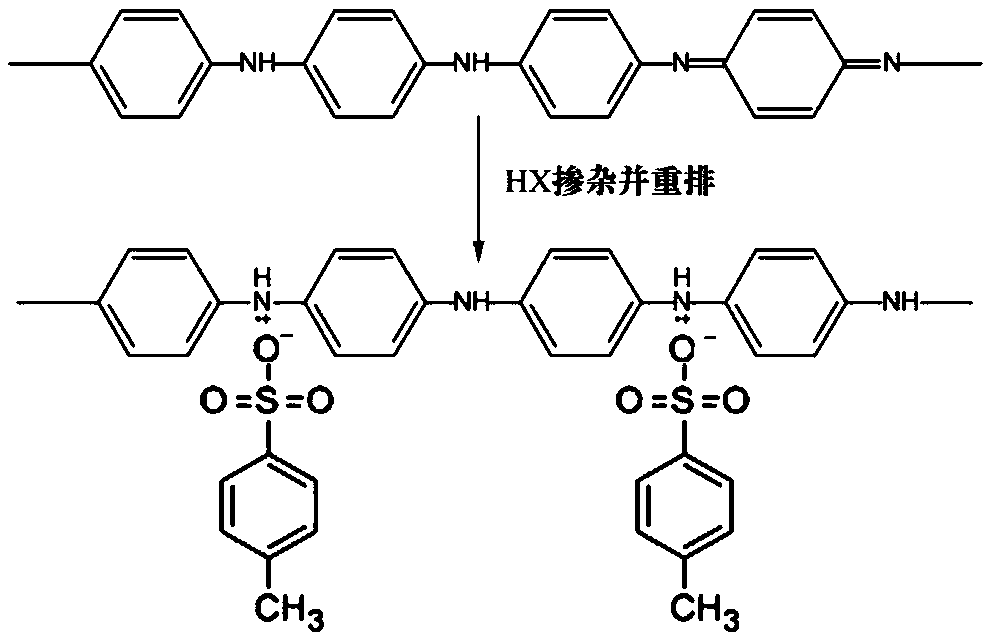

Method used

Image

Examples

Embodiment 1

[0042] A polyaniline film with an oriented rod-like structure, the preparation method of which is as follows: first, aniline and p-toluenesulfonic acid with a molar ratio of 1:10 are configured into an electrolyte solution, and the concentrations of aniline and p-toluenesulfonic acid in the electrolyte solution are respectively 0.05mol / L and 0.5mol / L, and then under the temperature condition of 20 ℃, the polyaniline film with oriented rod structure was deposited by electrochemical polymerization; a three-electrode system was adopted, and the three electrodes were working electrode, counter electrode and reference electrode; The working electrode is indium tin oxide conductive glass deposited with oriented rod-shaped polyaniline film, the counter electrode is platinum electrode, and the reference electrode is saturated calomel electrode; the constant potential mode is adopted, the voltage is 0.7V, and the voltage application time is 600s.

[0043] A polyaniline film with orient...

Embodiment 2

[0059] A polyaniline film with an oriented rod-like structure, the preparation method of which is as follows: first, aniline and p-toluenesulfonic acid with a molar ratio of 1:5 are configured into an electrolyte solution, and the concentrations of aniline and p-toluenesulfonic acid in the electrolyte solution are 0.16mol respectively / L and 0.8mol / L, and then under the temperature condition of 23 ℃, the polyaniline film with oriented rod structure was deposited by electrochemical polymerization; a three-electrode system was adopted, and the three electrodes were working electrode, counter electrode and reference electrode; The working electrode is a silicon wafer with polyaniline film deposited with an orientation rod structure, the counter electrode is a platinum electrode, and the reference electrode is a saturated calomel electrode; the constant current mode is adopted, the current is 3mA, and the current application time is 300s.

[0060] A finally obtained polyaniline fil...

Embodiment 3

[0062] A polyaniline film with an oriented rod-like structure, the preparation method of which is as follows: first, aniline and naphthalenesulfonic acid with a molar ratio of 1:5.4 are configured into an electrolyte solution, and the concentrations of aniline and naphthalenesulfonic acid in the electrolyte solution are respectively 0.28mol / L and 1.5mol / L, and then deposited by electrochemical polymerization at a temperature of 25°C to obtain a polyaniline film with an oriented rod-like structure; a three-electrode system was used, and the three electrodes were the working electrode, the counter electrode and the reference electrode; the working electrode The stainless steel electrode for depositing oriented rod-shaped polyaniline film, the counter electrode is a platinum electrode, and the reference electrode is a saturated calomel electrode; the constant potential mode is used, the voltage is 0.8V, the current is 5mA, and the voltage application time is 380s.

[0063] A polya...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com