Method for preparing polyelectrolyte composite nanofiltration membrane by using freeze drying technology

A polyelectrolyte and composite membrane technology, applied in the field of membrane separation, can solve the problems of difficult to obtain optimal membrane conditions, difficult to control the membrane process, large thickness of nanofiltration membrane, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

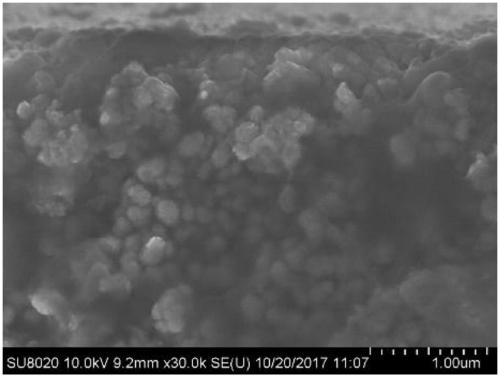

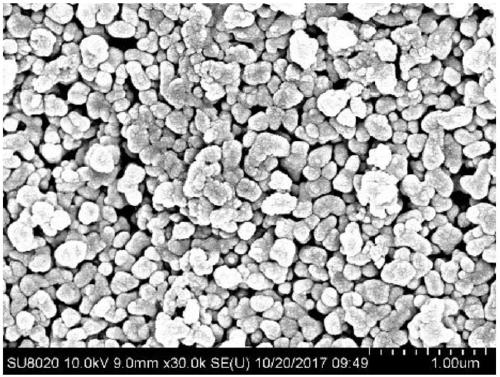

Image

Examples

Embodiment 1

[0021] The commercial porous membrane is made of alumina material, in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1 μm and a membrane area of 10 cm 2 , the selected polyanion is sodium alginate, the polycation is polyethyleneimine, and the selected solvent is deionized water.

[0022] Preparation method of f-SA / PEI composite nanofiltration membrane

[0023] (1) Rinse and pre-treat the aluminum oxide film with a length of about 5 cm with deionized water to remove organic matter, inorganic matter and microorganisms on the surface, and then dry it in an oven at 50°C;

[0024] (2) Polyethyleneimine was dissolved in deionized water to obtain solution A, and sodium alginate was dissolved in deionized water to obtain solution B. The concentrations of the two solutions were 0.05wt.% and 3.00wt.% respectively;

[0025] (3) Soak the treated alumina-based film in the prepared A solution for 3.5 hours, take it out and clean it, and then put it into an ...

Embodiment 2

[0030] The commercial porous membrane is made of alumina material, in the form of a tubular ultrafiltration membrane, with a membrane pore size of 1 μm and a membrane area of 10 cm 2 , the selected polyanion is sodium alginate, the polycation is polyethyleneimine, and the selected solvent is deionized water.

[0031] Preparation method of f-SA / PEI composite nanofiltration membrane

[0032] (1) Rinse and pre-treat the aluminum oxide film with a length of about 5 cm with deionized water to remove organic matter, inorganic matter and microorganisms on the surface, and then dry it in an oven at 50°C;

[0033] (2) Polyethyleneimine was dissolved in deionized water to obtain solution A, and sodium alginate was dissolved in deionized water to obtain solution B. The concentrations of the two solutions were 3.00wt.% and 0.05wt.% respectively;

[0034] (3) Soak the treated alumina-based film in the prepared A solution for 0.5h, then take it out for cleaning, and finally put it into a...

Embodiment 3

[0039] The commercial porous membrane is made of alumina material, in the form of a tubular ultrafiltration membrane with a membrane pore size of 0.1 μm and a membrane area of 10 cm 2 , the selected polyanion is sodium alginate, the polycation is polyethyleneimine, and the selected solvent is deionized water.

[0040]Preparation method of f-SA / PEI composite nanofiltration membrane

[0041] (1) Rinse and pre-treat the aluminum oxide film with a length of about 5 cm with deionized water to remove organic matter, inorganic matter and microorganisms on the surface, and then dry it in an oven at 50°C;

[0042] (2) Polyethyleneimine was dissolved in deionized water to obtain solution A, and sodium alginate was dissolved in deionized water to obtain solution B. The concentrations of the two solutions were 0.25wt.% and 1.00wt.% respectively;

[0043] (3) Soak the treated alumina-based film in the prepared A solution for 1 hour, then take it out for cleaning, and finally put it into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com